Automobile front bumper tensile strength test device

A front bumper and tensile strength technology, which is applied in the field of automobile front bumper tensile strength testing devices, can solve the problems of no testing equipment, etc., and achieve the effects of convenient, fast and firm clamping, improved detection efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

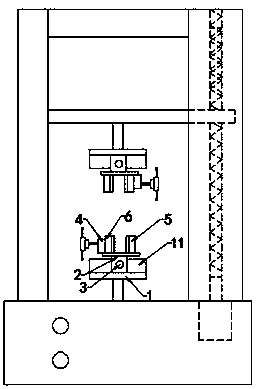

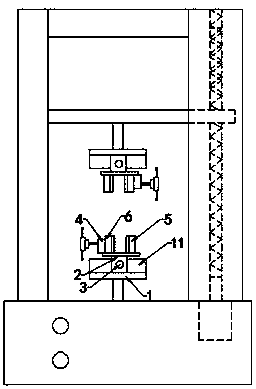

[0010] Depend on figure 1 Known, a kind of automobile front bumper tensile strength testing device, is made up of control box, frame, upper clamping part and lower clamping part; Described control box upper surface middle is provided with lower clamping part, frame horizontal Striding on the control box, the frame is movably connected with an upper clamping part, and the upper clamping part is located above the lower clamping part; the structure of the upper clamping part is the same as that of the lower clamping part. 2. The adjustment hand wheel 3, the left fixed block 4, the right fixed clamp block 5 and the left moving clamp block 6 with the adjustment wheel are composed. The base 1 is fixed in the middle of the upper surface of the control box, and the top of the base 1 is provided with a slide rail 11 and a slide plate The seat 2 is movably connected on the slide rail 11, and the adjusting handwheel 3 is arranged on the skateboard seat 2. When the skateboard seat 2 moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com