Fitting clamp for fine-pitch tube bundle

A small-pitch, fixture technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of difficult assembly of welding counterparts and hinder the production process, so as to achieve convenient and fast clamping and disassembly, and ensure manufacturing quality and cycle time , Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

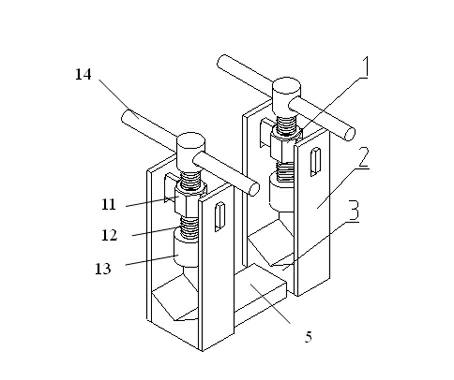

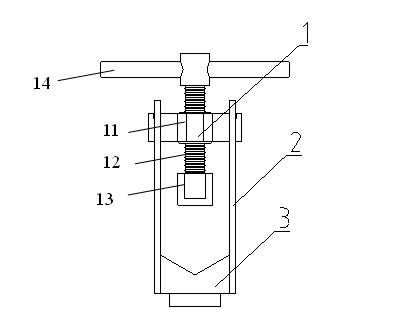

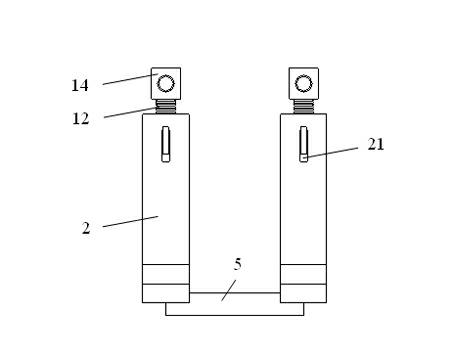

[0018] The following combination Figure 1 ~ Figure 4 , a preferred embodiment of the present invention is described in detail.

[0019] Such as Figure 1 ~ Figure 3 As shown, the pairing fixture of the small-pitch tube row includes two pairing fixture assemblies connected concentrically through the connecting plate 5, and each pairing fixture assembly includes two inserting plates 2, which are arranged at the bottom ends of the two inserting plates 2 The supporting block 3 between them, and the fastening device 1 arranged between the top ends of the two inserting boards 2 .

[0020] Among them, such as Figure 4 As shown, the thickness of the insert plate 2 is smaller than the gap between adjacent pipes 4; and the interval width between the two insert plates 2 is set correspondingly to the tube row pitch, so that each insert Each plate 2 can be inserted from the gap between adjacent tubes 4 .

[0021] The supporting block 3 is arranged in a V shape or a U shape, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com