Engine cylinder body top surface inclined hole drilling fixture

A technology for drilling inclined holes in the engine block, which is applied in clamping, manufacturing tools, and drilling templates for workpieces. It can solve problems such as the complex shape of the engine block structure and the impact on engine performance, and achieve improved firmness and stability. High performance, improved processing accuracy, novel and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

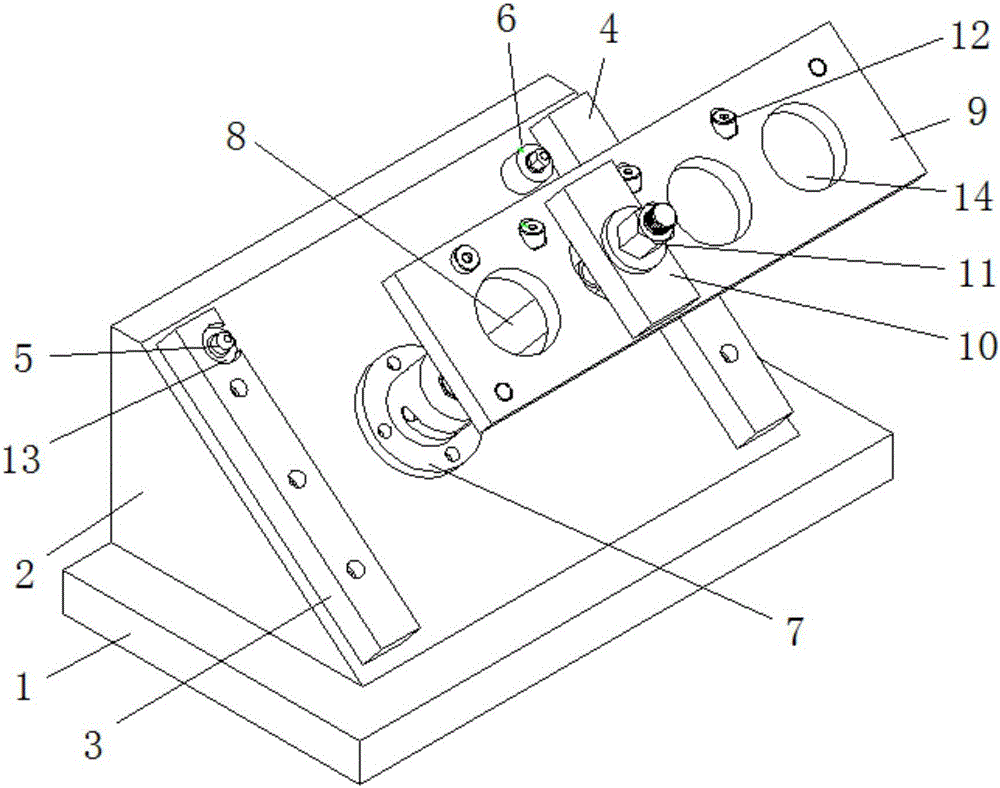

[0018] See attached picture:

[0019] The jig for drilling inclined holes on the top surface of the engine block includes a base 1, a trapezoidal support body 2 is provided on the upper end of the base 1, and a left support block 3 that cooperates with the bottom surface of the engine block is arranged symmetrically on both sides of the front slope of the support body 2 , the right support block 4, the support body slope between the left support block 3 and the right support block 4 upper ends are respectively provided with the first positioning pin 5, the second positioning pin 6,

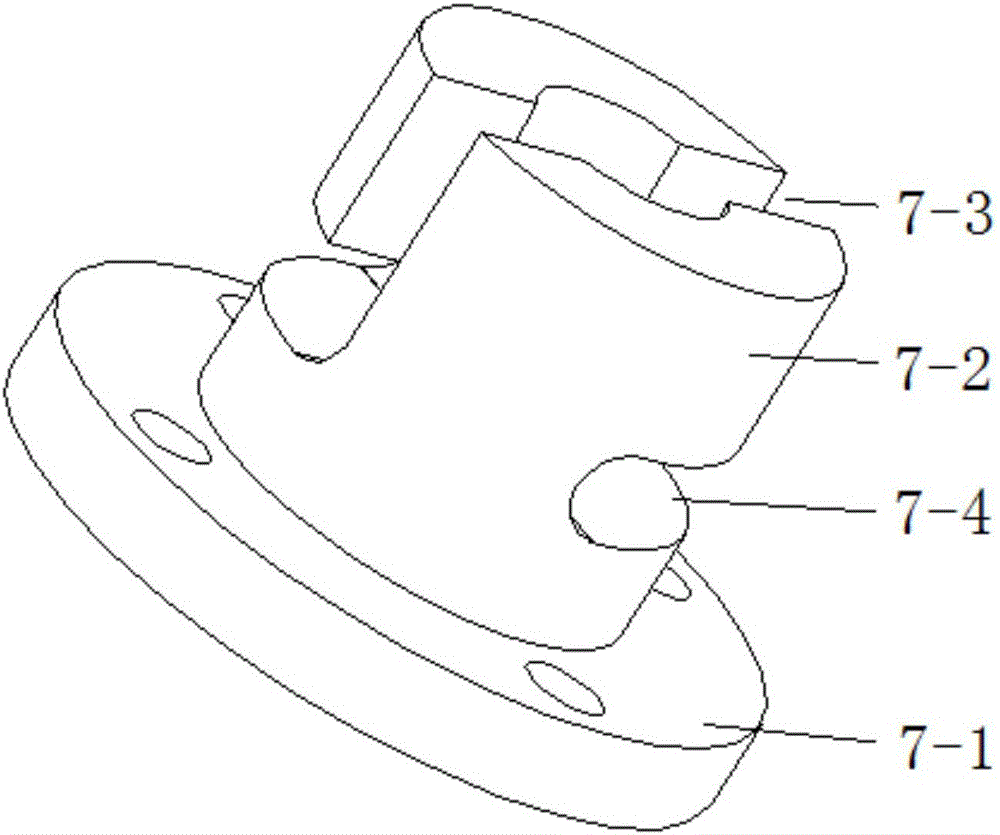

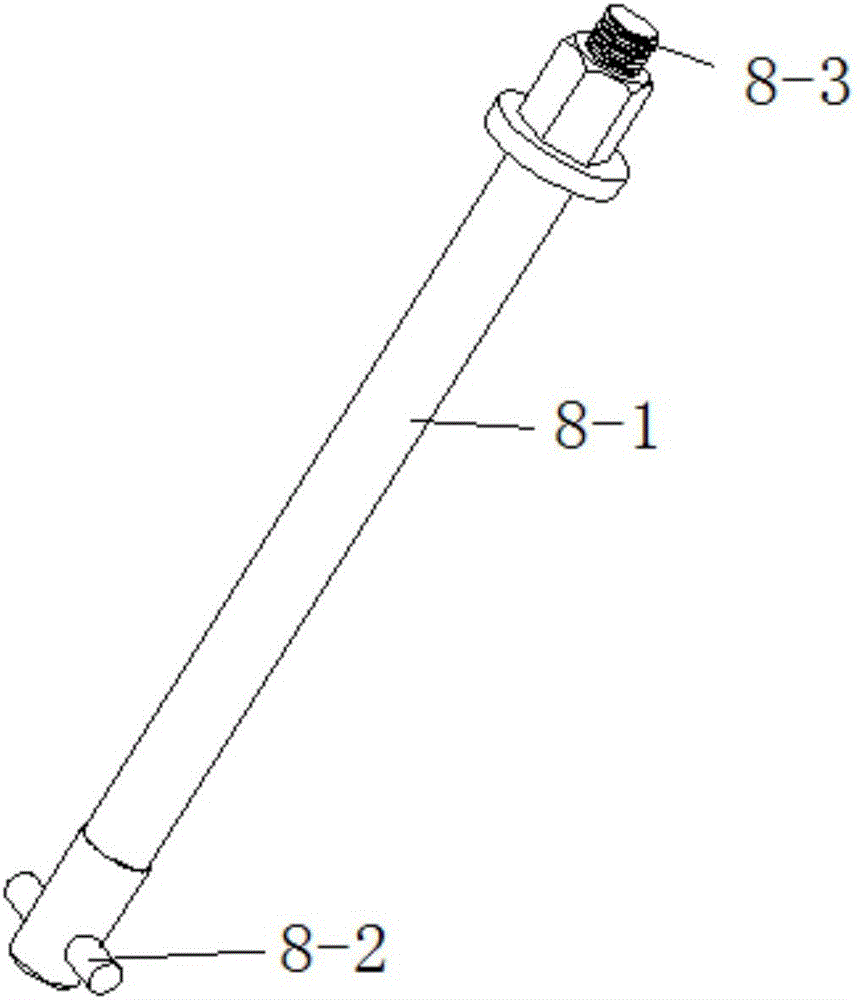

[0020] The middle part of the support body 2 slope is provided with a detachable mounting seat 7, and the detachable mounting seat 7 is equipped with a connecting rod 8 that passes through the cylinder liner hole of the engine block during work. , the compression plate 10, the top of the connecting rod 8 is screwed with the lock nut 11 for locking the compression plate, and the drill bushing mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com