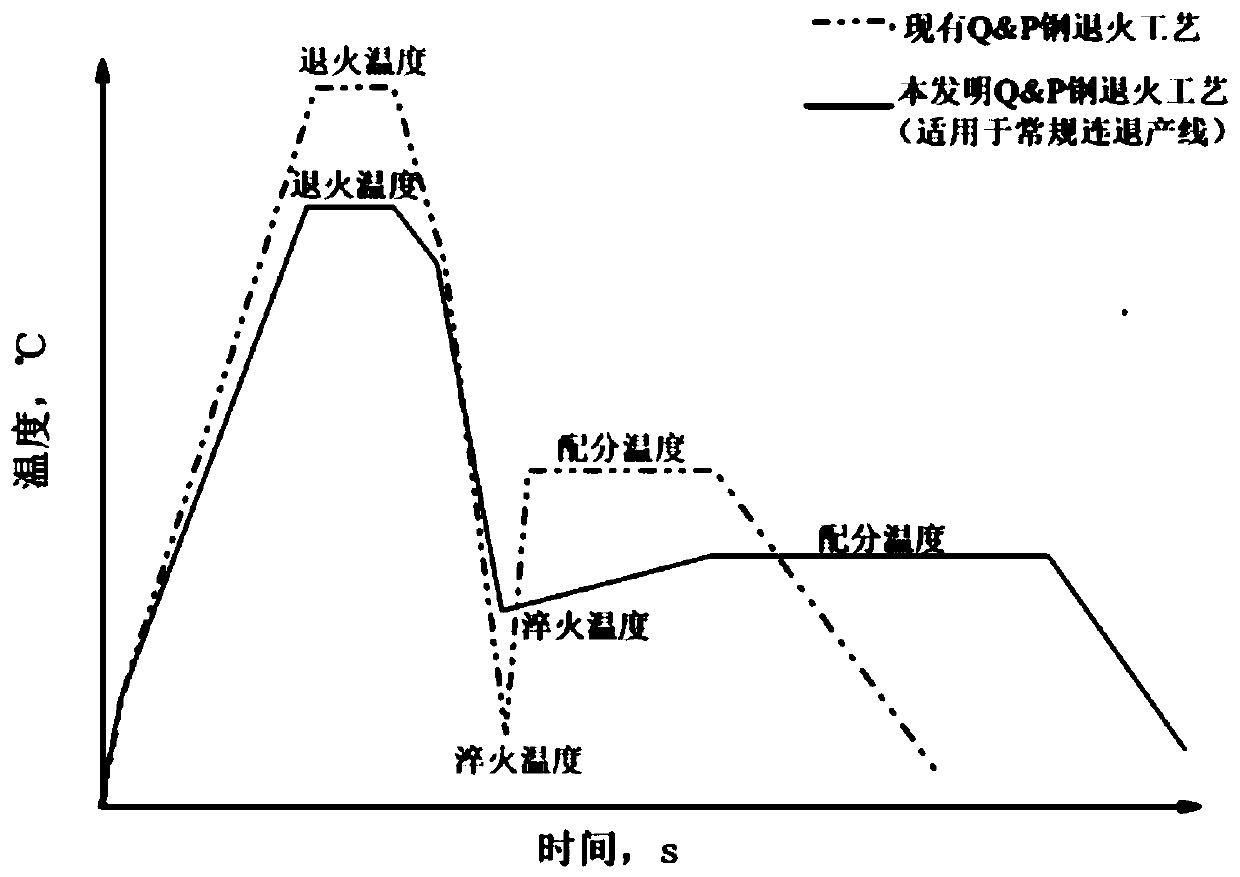

980 MPa-grade cold-rolled Q&P steel suitable for conventional continuous annealing production line and manufacturing method thereof

A manufacturing method, 980mpa technology, applied in the field of material heat treatment, can solve the problems that cannot be realized in large-scale production, the process of the two-partition method is complicated, and cannot be realized in large-scale production, so as to inhibit the precipitation of carbides, improve toughness, The effect of excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 9

[0042] A 980MPa grade cold-rolled Q&P steel suitable for conventional continuous annealing production lines, the chemical composition mass percentage of the steel is shown in Table 1.

[0043] Embodiment 1-embodiment 9 described is applicable to the manufacturing method of the 980MPa level cold-rolled Q&P steel of conventional continuous annealing production line, and the manufacturing process flow is:

[0044] Smelting → continuous casting → hot rolling → pickling cold rolling → continuous annealing → finished product.

[0045] Specifically:

[0046] (1) Smelting and continuous casting: suitable for converter, electric furnace and induction furnace smelting, using continuous casting to produce slabs, using electromagnetic stirring and dynamic light reduction devices in the pouring process to reduce component segregation during solidification;

[0047] (2) Continuous hot rolling of billets or ingots: the billets are heated at a temperature of 1200-1260°C, held for 2-3 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com