Steel for high strength fastener for marine environment

A marine environment, high-strength technology, applied in the field of steel, can solve problems such as the effect is questionable, and achieve the effect of reducing probability and risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

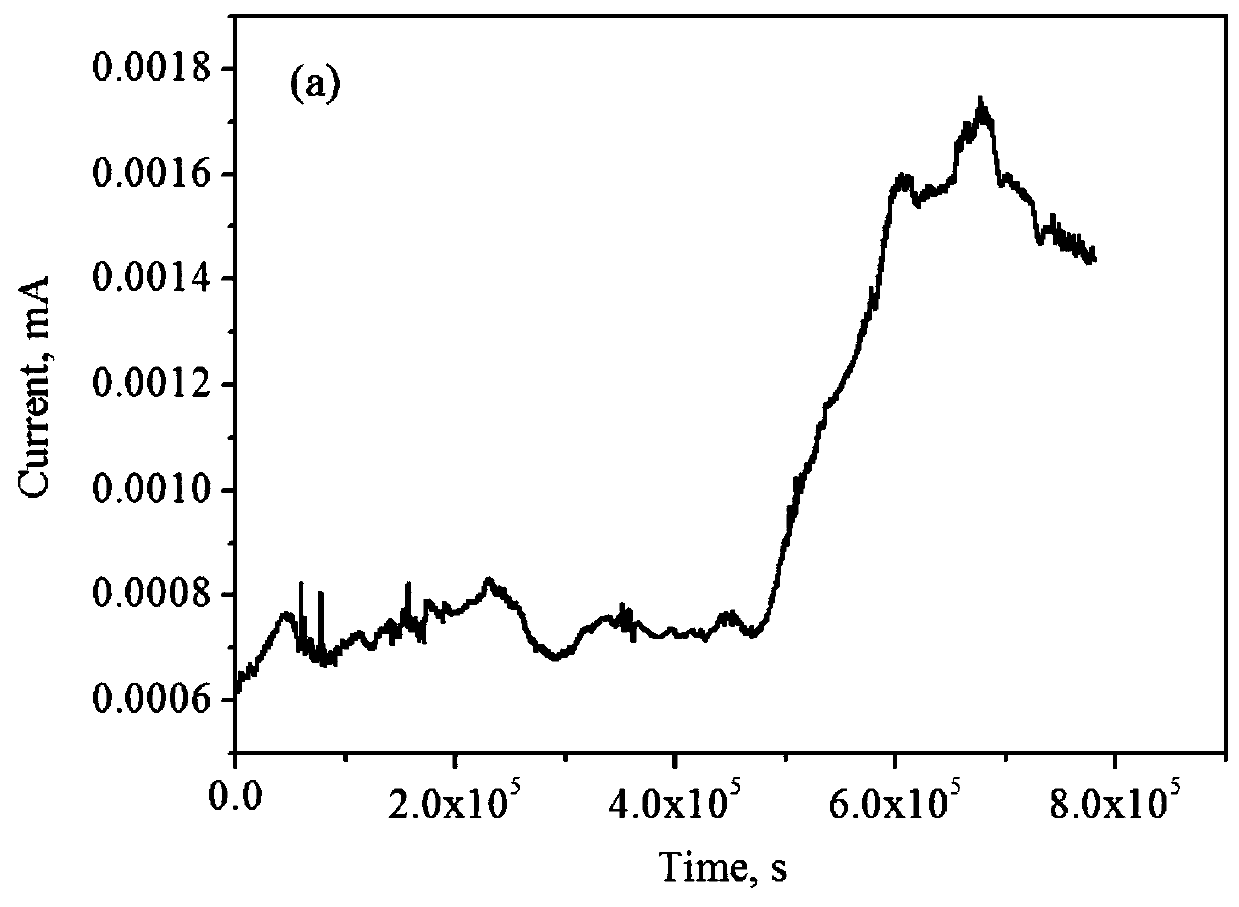

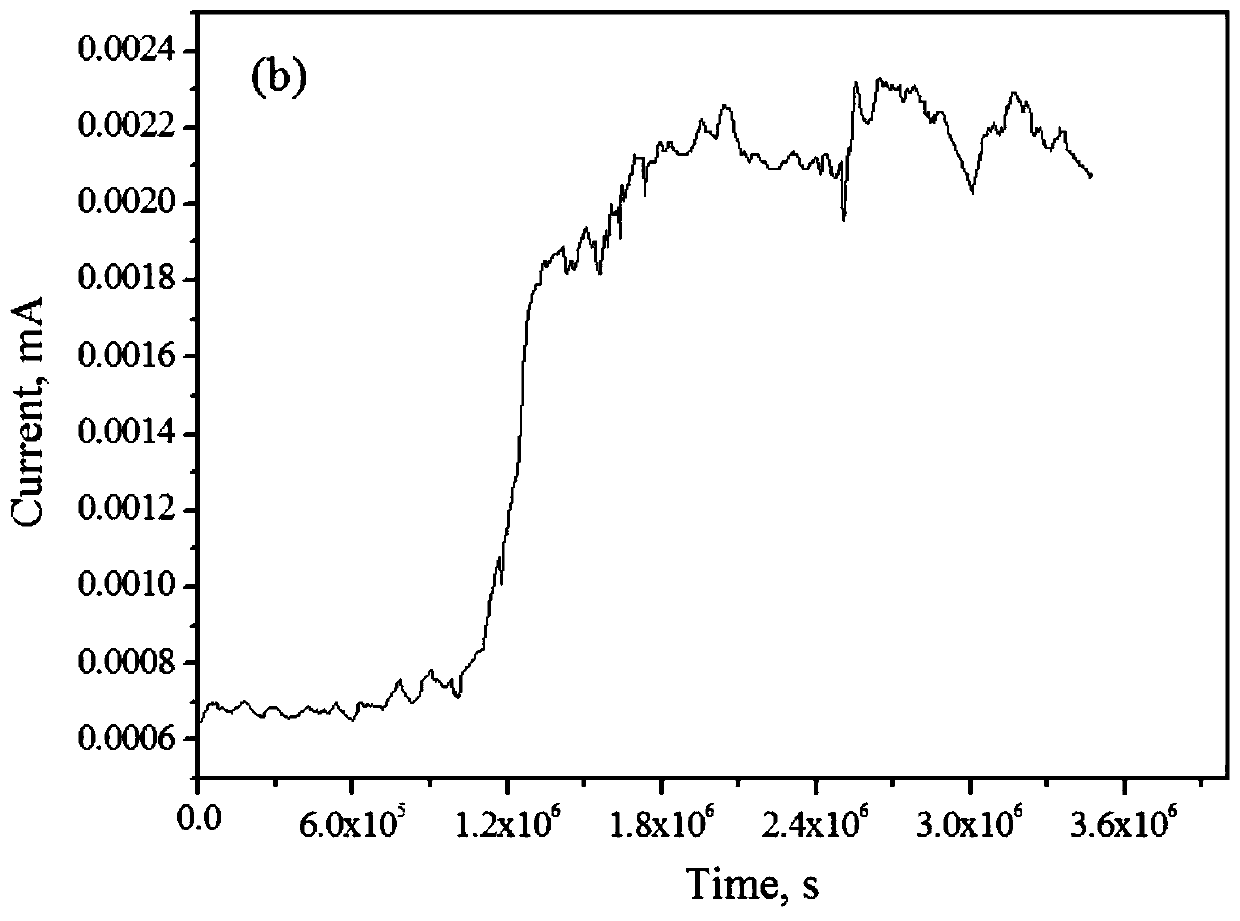

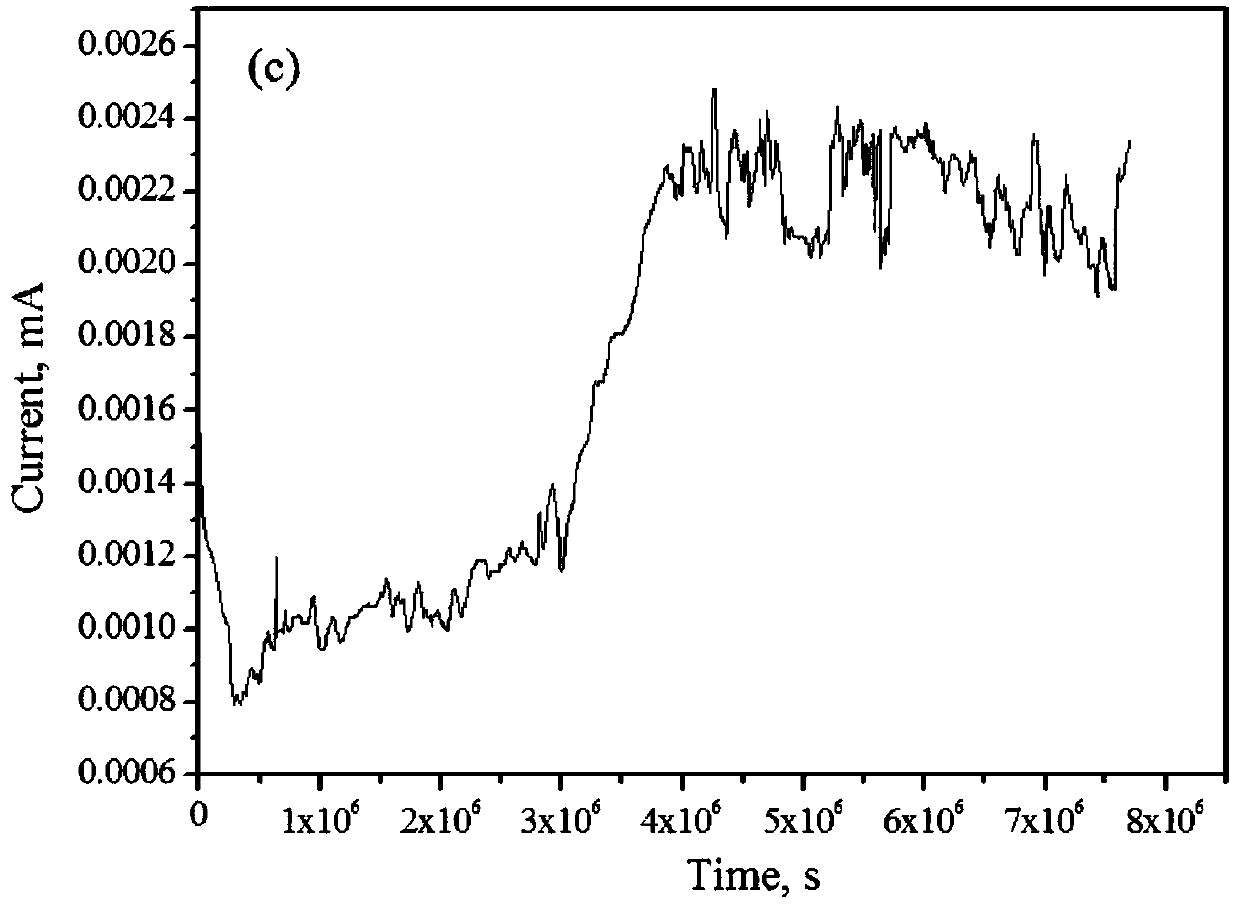

Image

Examples

specific Embodiment approach

[0047] The steel grades A1-A3 of the present invention and the comparative steel grade A4 were poured into steel ingots through a 50kg vacuum melting furnace, the chemical composition was as shown above, forged and cut to Φ45mm, and peeled to Φ40mm polished rods for subsequent test samples.

[0048] All steel types in this example are quenched + tempered to obtain the tempered martensite matrix, and the specific heat treatment process is:

[0049] A1: 870°C, water cooling; 550°C, air cooling;

[0050] A2: 900°C, water cooling, 590°C, water cooling;

[0051] A3: 900°C, water cooling, 620°C, water cooling;

[0052] A4: 860°C, water cooling, 500°C, air cooling.

[0053] In addition, the difference in the microstructure obtained in this example is that there is a small amount of reversed austenite structure in steels A1, A2, and A3. It can be seen from the results of mechanical properties that A1 steel has better strength-plastic compatibility, which is due to the increase of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com