Accumulator

A technology of accumulator and bellows is applied in the direction of accumulator device, actuator accumulator, fluid pressure actuating device, etc., to achieve the effect of ensuring sealing, reducing the number of parts, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] Next, embodiments of the present invention will be described based on the drawings.

no. 1 example ·

[0095] First embodiment...

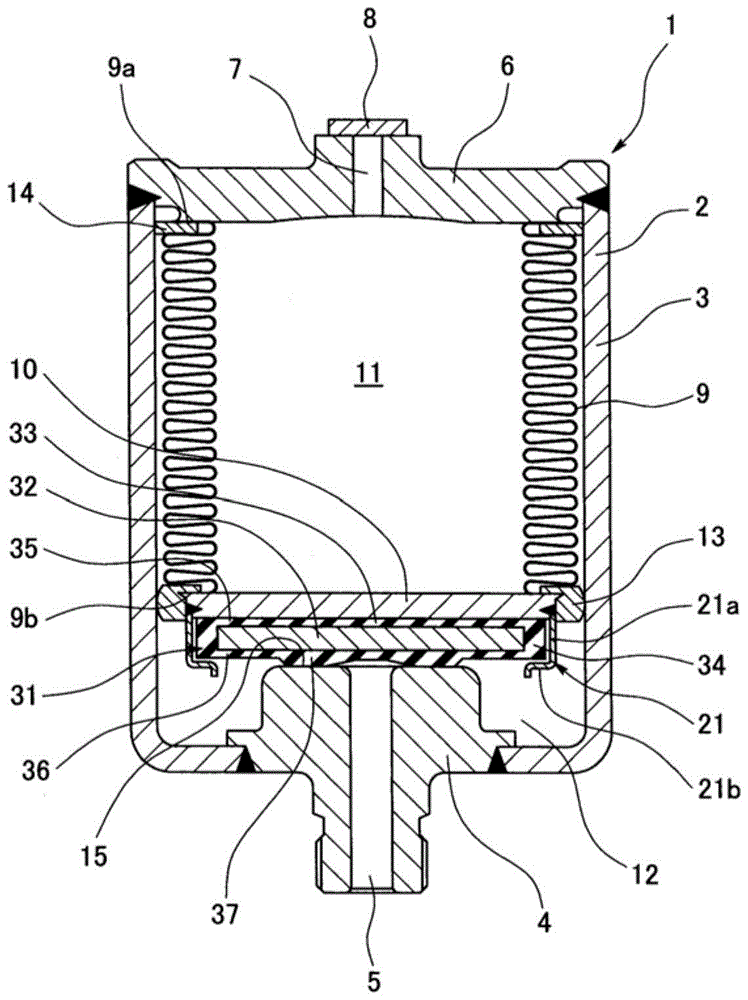

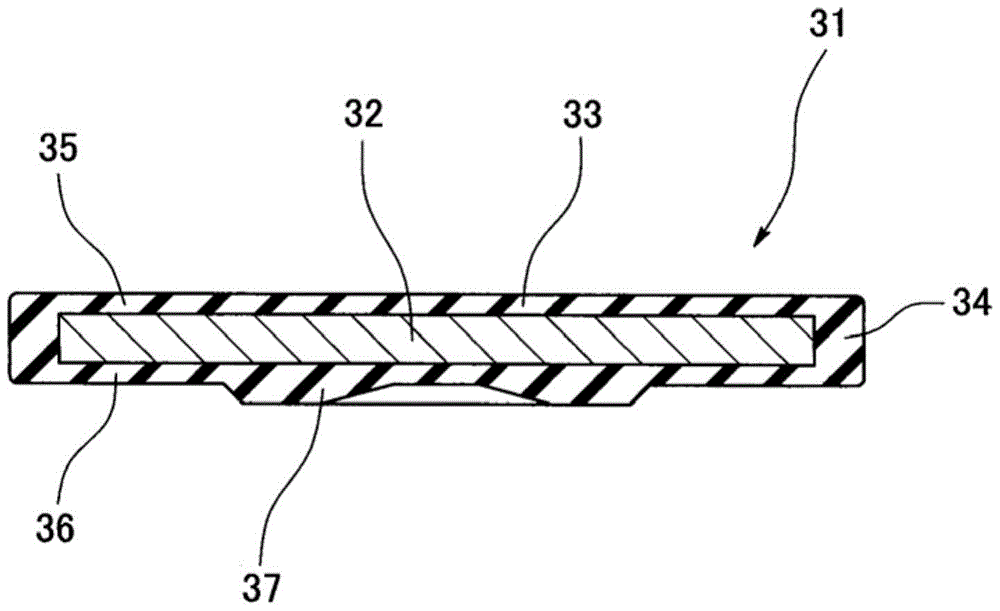

[0096] Figure 1 to Figure 5 The accumulator 1 according to the first embodiment of the present invention is shown. The accumulator 1 of this embodiment is a metal bellows type accumulator using a metal bellows as the bellows 9, and is configured as follows.

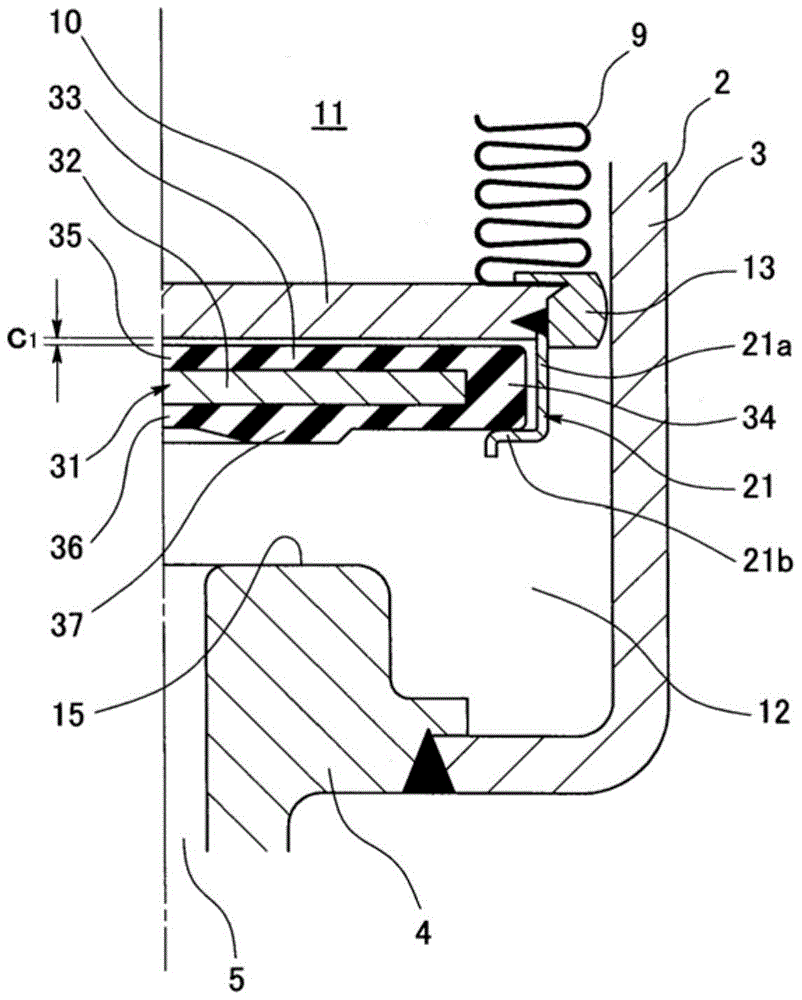

[0097] That is, if figure 1As shown, an accumulator case 2 having a port hole 5 connected to a pressure piping of an unillustrated device is provided, and a bellows 9 and a bellows cover 10 are arranged inside the case 2, and the parts of the case 2 are The inner space is partitioned into a gas chamber 11 in which a high-pressure gas (for example, nitrogen gas) is sealed, and a liquid chamber 12 in communication with the port hole 5 . As the housing 2, the bottomed cylindrical housing 3 is fixed (welded) to the bottom center of the housing 3 and the oil port 4 provided with the port hole 5 is fixed (welded) to the upper end of the housing 3. The housing is composed of the combination of ...

no. 3 example ·

[0122] (2) The third embodiment...

[0123] As a third embodiment, such as Figure 9 ~ Figure 11As shown, grooves 39 formed by partially reducing the thickness of the flexible portion 34 in the radial direction are provided on the port-side end surface and the non-port-side end surface of the flexible portion 34 of the sealing member 31 . According to this structure, similarly to the above-mentioned second embodiment, the amount of shear deformation of the flexible portion 34 can be increased, and the distance between the seal member 31 and the seal bracket 21 and between the seal member 31 and the bellows cover 10 can be increased. relative movement. In addition, in the figure, the outer peripheral protrusion 38 according to the above-mentioned second embodiment is provided together on the port side end face of the flexible portion 34, therefore, the groove portion 39 is provided on the inner peripheral side of the outer peripheral protrusion 38 on the port side end face. ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com