Valve timing control apparatus for internal combustion engine

A control device and valve timing technology, which is applied in the direction of valve devices, valve details, mechanical equipment, etc., can solve problems such as decreased accuracy and unstable control of valve timing control devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach 〕

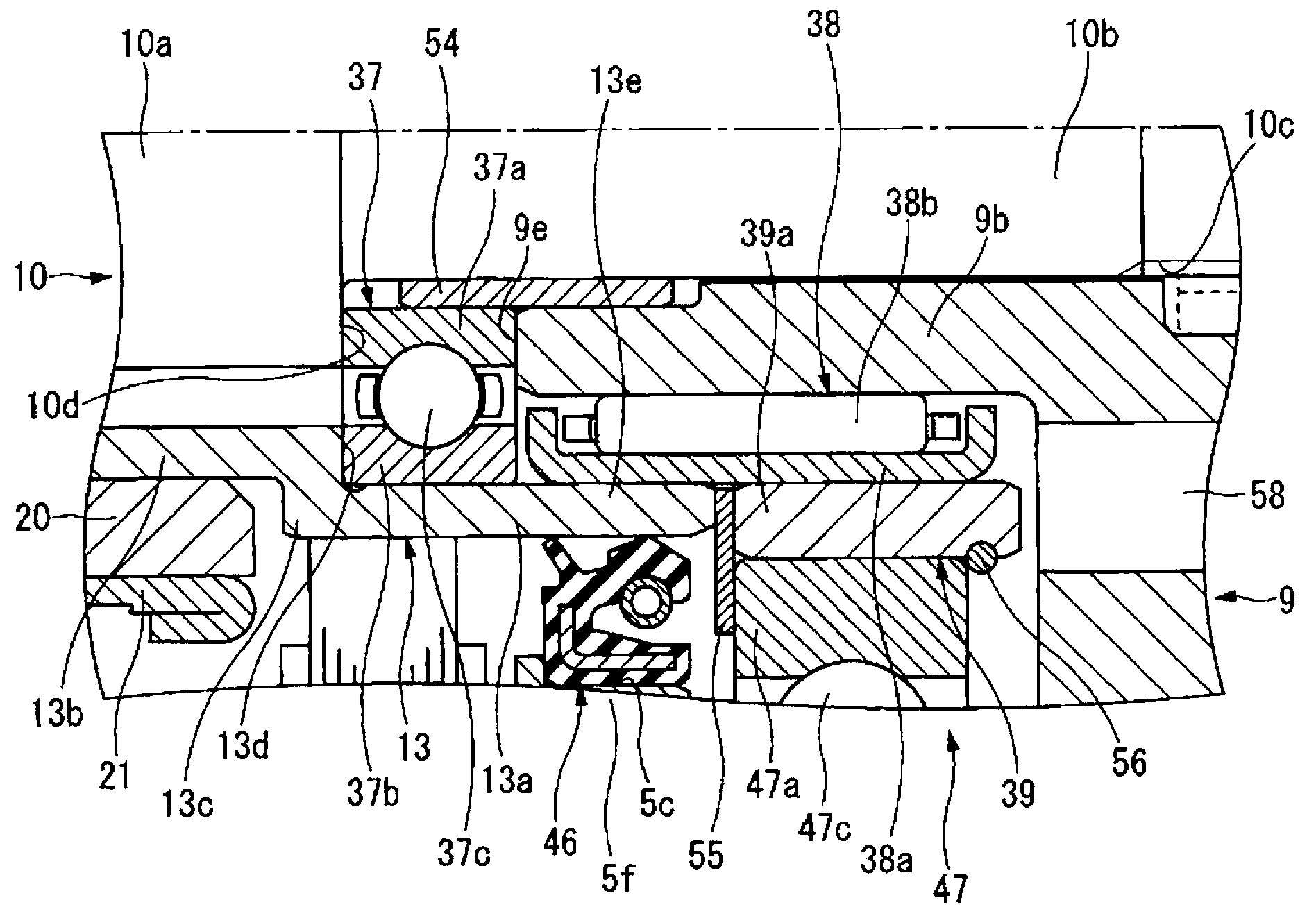

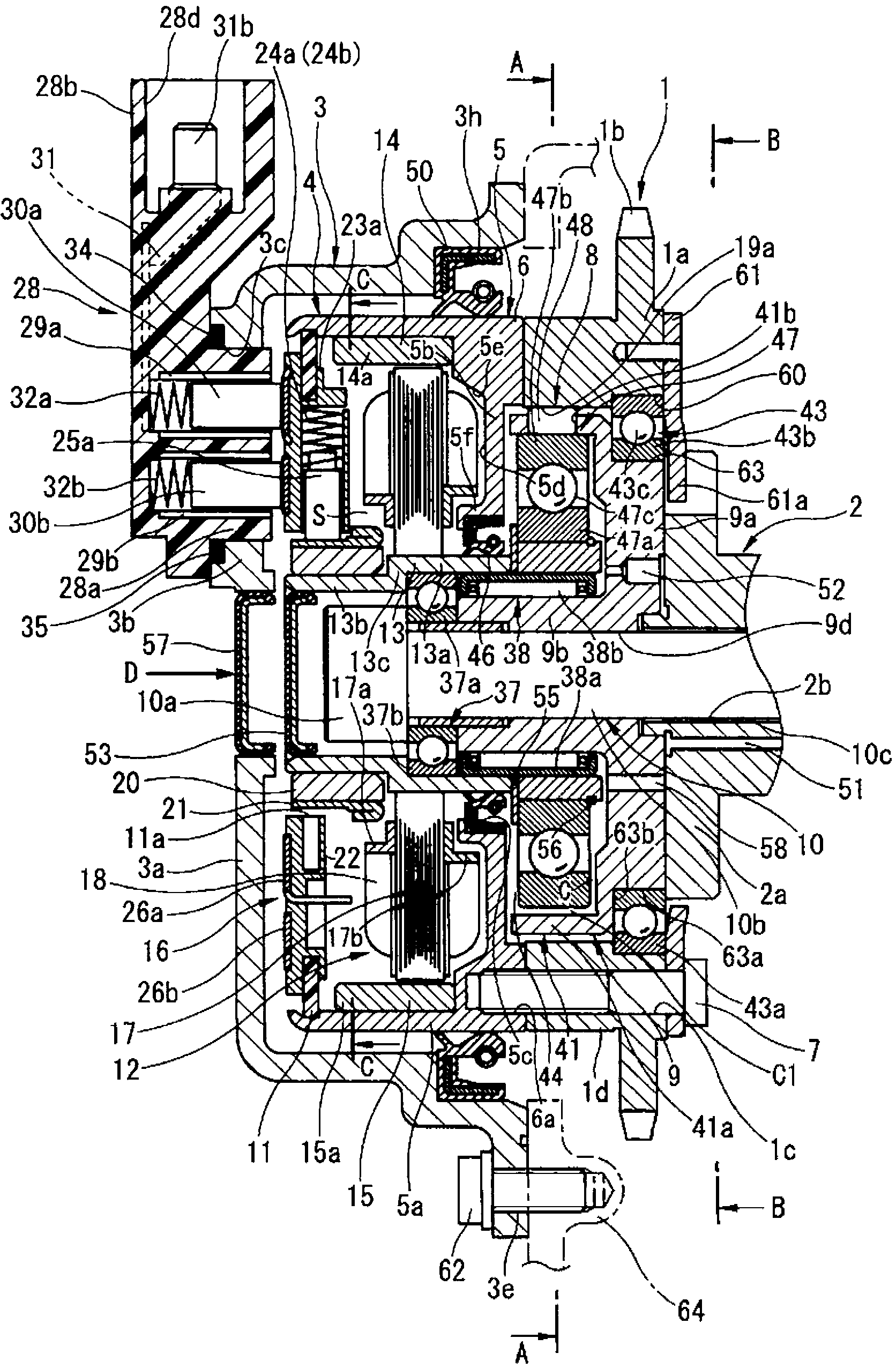

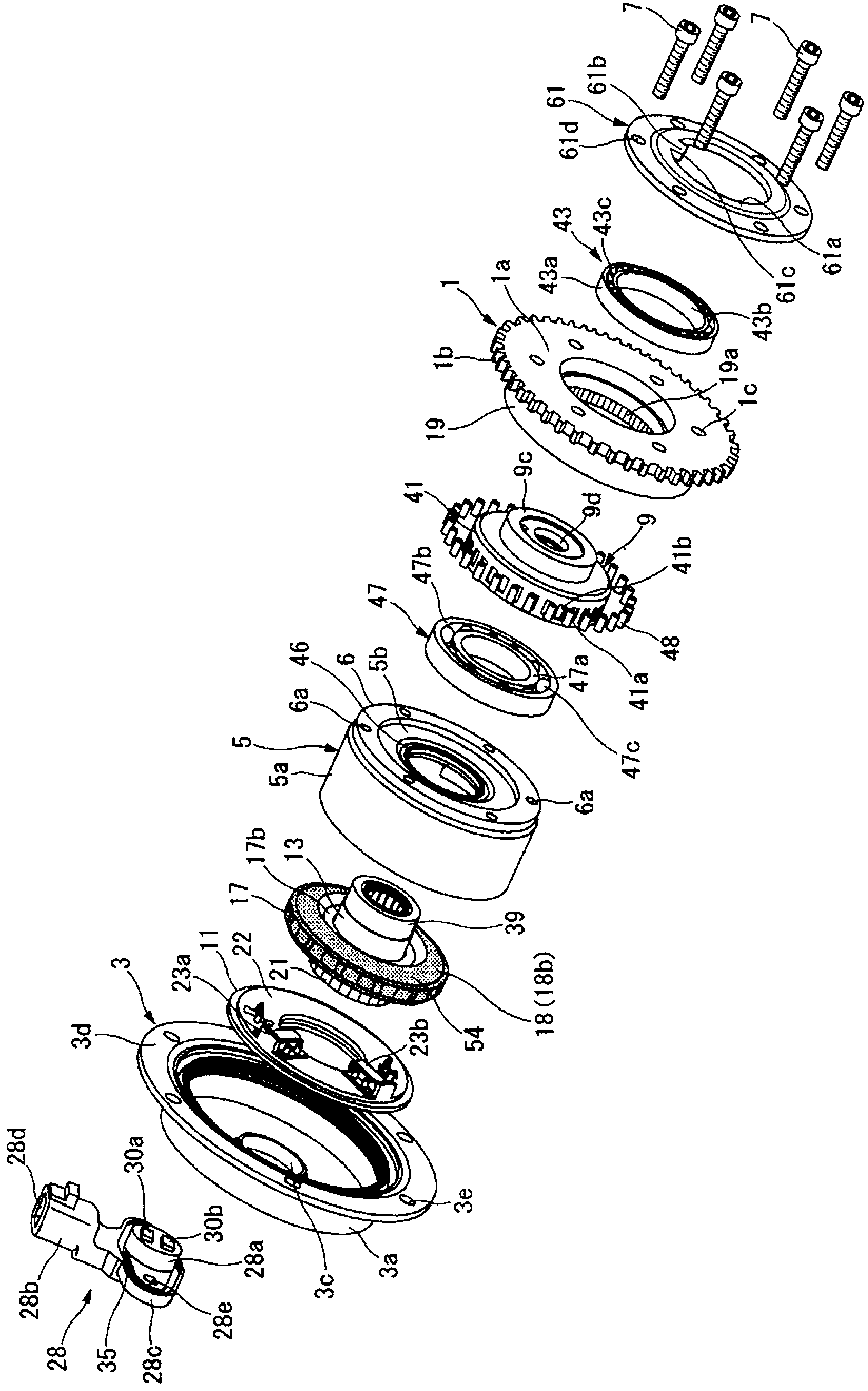

[0148] Figure 7 and Figure 8 In the second embodiment of the present invention, the thickness Q of the large-diameter portion 13 a of the motor shaft 13 is slightly larger than that of the small-diameter portion 13 b, and the axial length L is also increased by the thickness of the washer 55 .

[0149] Therefore, the inner peripheral side of the front end surface 13f of the large-diameter portion 13a abuts against the front end surface of the eccentric cam 39 from the axial direction, and the outer peripheral side of the front end surface 13f abuts against the side surface of the inner ring 47a of the ball bearing 47 through a step. catch. Therefore, axial movement of the inner ring 47a is restricted by cooperation of the front end surface 13f of the large-diameter portion 13a and the snap ring 56 .

[0150] Therefore, according to this embodiment, the washer 55 of the first embodiment can be eliminated, so that the number of parts can be reduced, and the manufacturing wor...

no. 3 approach 〕

[0153] Figure 9 The third embodiment is shown, and the outer diameter of the needle bearing 38 is formed larger than that of the first and second embodiments. In this case, the motor shaft 13 is formed with a The annular notch 13 g is formed slightly smaller than the thickness of the eccentric cam 39 .

[0154] In this way, by increasing the outer diameter of the needle bearing 38, the support rigidity of the motor shaft 13 and the eccentric cam 39 pressed into the outer peripheral surface is improved, and the bonding strength of both 13 and 39 is improved.

[0155] The other configurations are the same as those of the first embodiment, so the same effects can be obtained.

no. 4 approach 〕

[0157] Figure 10 The fourth embodiment is shown. Like the third embodiment, the outer diameter of the needle bearing 38 is formed larger, and the wall thickness Q and axial length L of the large-diameter portion 13a of the motor shaft 13 are set to be the same as those of the second embodiment. It is also larger, whereby the washer 55 can be eliminated and the support rigidity of the motor shaft 13 and the eccentric cam 39 can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com