Adhesive tape preventing adhesion by aquatic organisms

A technology for aquatic organisms and adhesive tapes, applied in the direction of pollution prevention methods, film/sheet-like adhesives, adhesives, etc. Effects of suppression of plastic deformation, excellent recyclability, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

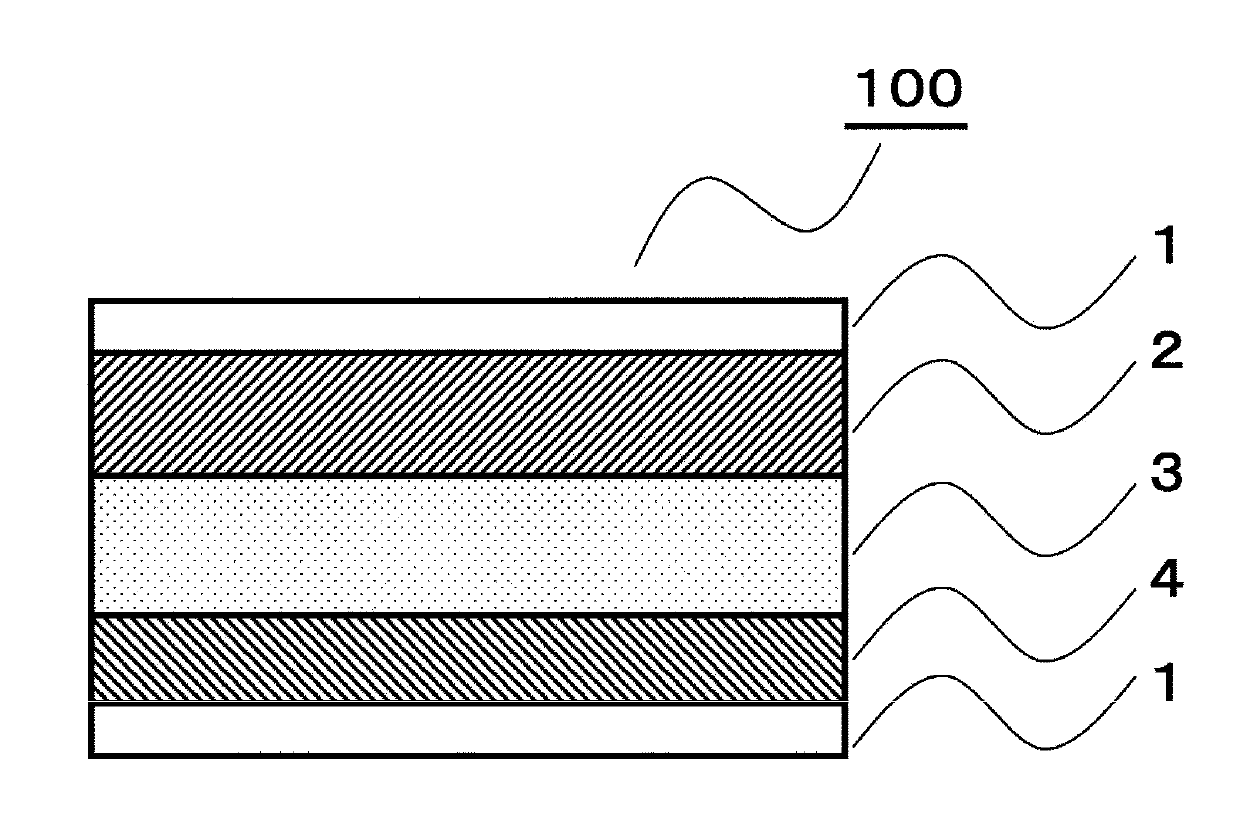

Image

Examples

Embodiment

[0124] Hereinafter, the present invention will be specifically described through examples, but the present invention is not limited in any way by these examples.

[0125]

[0126] According to JIS7161, JIS7162, JIS7127, use a tensile testing machine (AUTOGRAPH AGS-X, produced by Shimadzu Corporation) and analysis software (TRAPEZIUM X, produced by Shimadzu Corporation) to measure the elongation and elongation of the substrate layer Stress at the breaking point.

[0127]

[0128] The adhesive of the adhesive layer was transferred onto a polyester film (trade name "S-10", manufactured by Toray Co., Ltd., thickness 38 μm) using a hand roller to obtain an adhesive sheet with a substrate. Cut it into a test piece size of 80mm×20mm. A plastic FRP board reinforced with a glass cloth in an epoxy resin of 30 mm × 100 mm × thickness 2 mm as an adherend was used. The test piece was reciprocated once on the adherend with a 2 kg roller to stick it on the adherend, and after leaving it at 23°C...

manufacture example 1

[0148]

[0149] 71 parts by weight of isobornyl acrylate (trade name "IBXA", manufactured by Osaka Organic Chemical Industry Co., Ltd.) as a (meth)acrylic monomer, and n-butyl acrylate were added to a reaction vessel equipped with a cooling tube, a thermometer and a stirring device Ester (BA, manufactured by Toagosei Co., Ltd.) 19 parts by weight, acrylic acid (AA) 10 parts by weight, poly(oxytetramethylene) glycol (PTMG650, manufactured by Mitsubishi Chemical Co., Ltd.) with a number average molecular weight of 650 as a polyol ) 68.4 parts by weight, 0.01 parts by weight of dibutyltin dilaurate (DBTL) as a catalyst, and 25.5 parts by weight of hydrogenated xylylene diisocyanate (HXDI, Mitsui Chemical Polyurethane Co., Ltd.) while stirring. And react at 65°C for 5 hours to obtain a polyurethane-acrylic monomer mixture. After that, 6.1 parts by weight of hydroxyethyl acrylate (trade name "ACRYCS HEA", manufactured by Toagosei Co., Ltd.) was added and reacted at 65°C for 1 hour, ...

manufacture example 2

[0153]

[0154] A reaction vessel equipped with a cooling tube, a nitrogen introduction tube, a thermometer, and a stirrer was charged with 90 parts by weight of 2-ethylhexyl acrylate (2EHA, manufactured by Toagosei Co., Ltd.) as a (meth)acrylic monomer, and acrylic acid (AA) 10 parts by weight of 2,2-dimethoxy-1,2-diphenylethane-1-one (trade name "Irgacure651", manufactured by BASF) as a photopolymerization initiator, 0.05 parts by weight, They are dispersed, and while stirring, UV irradiation is performed from the upper part under a nitrogen stream to convert part of the monomers into polymers and adjust the viscosity to be coatable, thereby obtaining an acrylic monomer mixture. Add 0.08 parts by weight of 1,6-hexanediol diacrylate (HDDA) as a cross-linking agent to the acrylic monomer mixture, and use an applicator on the separator (trade name "MRF50", manufactured by Mitsubishi Plastics Co., Ltd.) , The thickness of 50μm) surface coating, hand-pressing roller to paste the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com