Ultrasonic rolling textured AlCrN coating on matrix surface and preparation process

A technology of ultrasonic rolling and preparation process, applied in metal material coating process, coating, vacuum evaporation coating and other directions, can solve the problems of single coating structure and preparation process, and achieve the improvement of microhardness and friction reduction. Anti-wear properties, enhanced bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

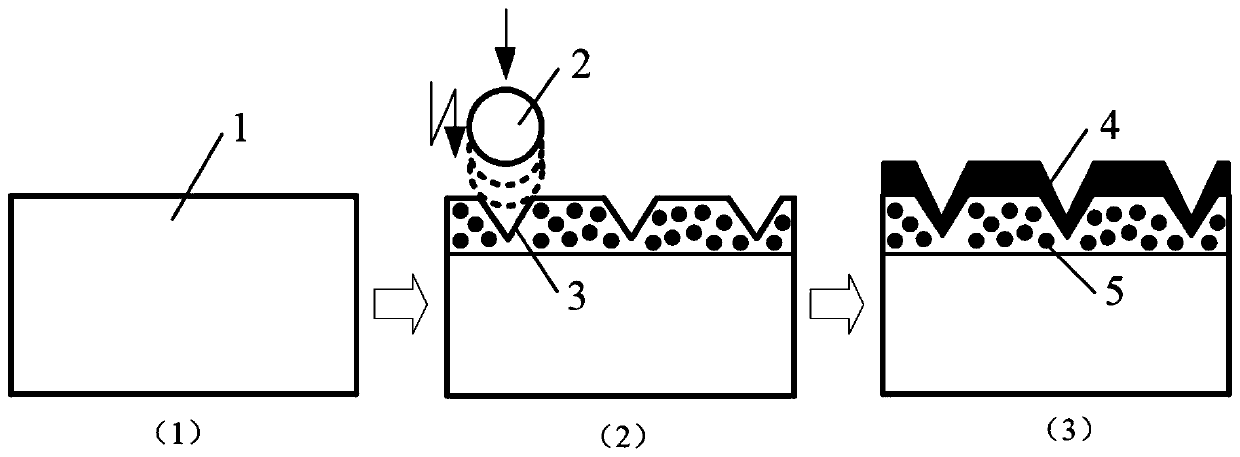

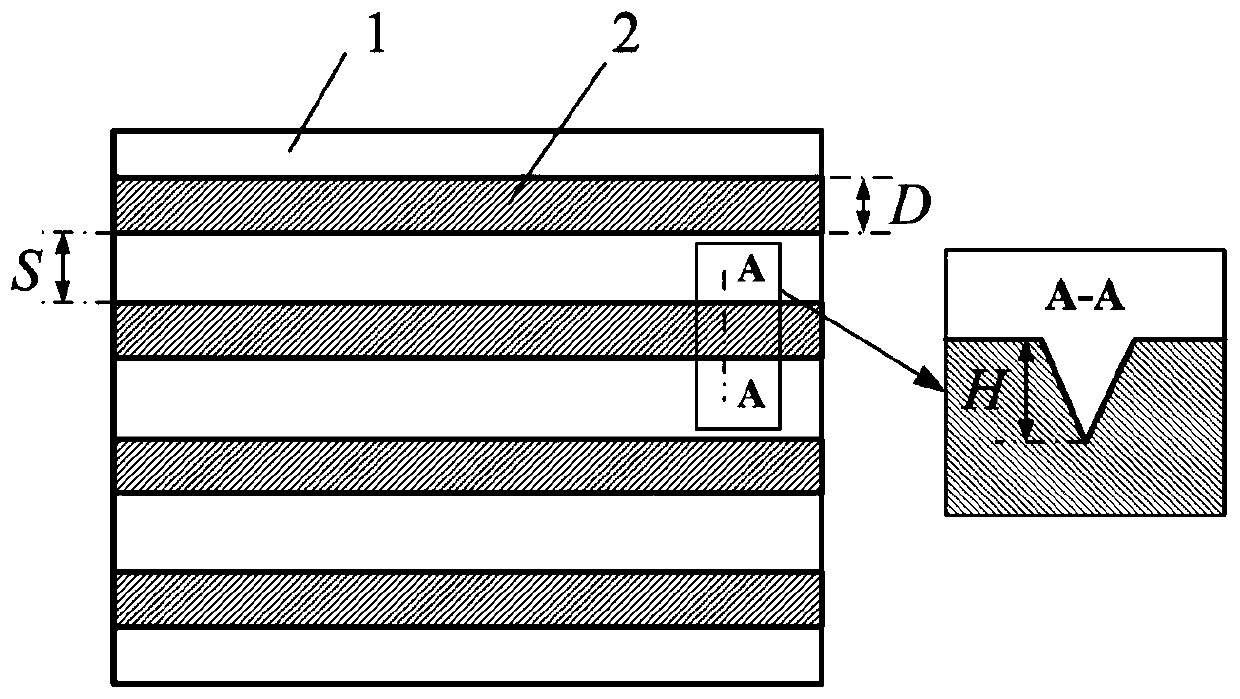

[0026] A typical embodiment of the present invention provides a preparation process for the ultrasonic rolling textured AlCrN coating on the surface of the substrate. First, the ultrasonic rolling texture is carried out on the surface of the substrate metal, and then the surface of the textured substrate metal is textured. Preparation of AlCrN coating;

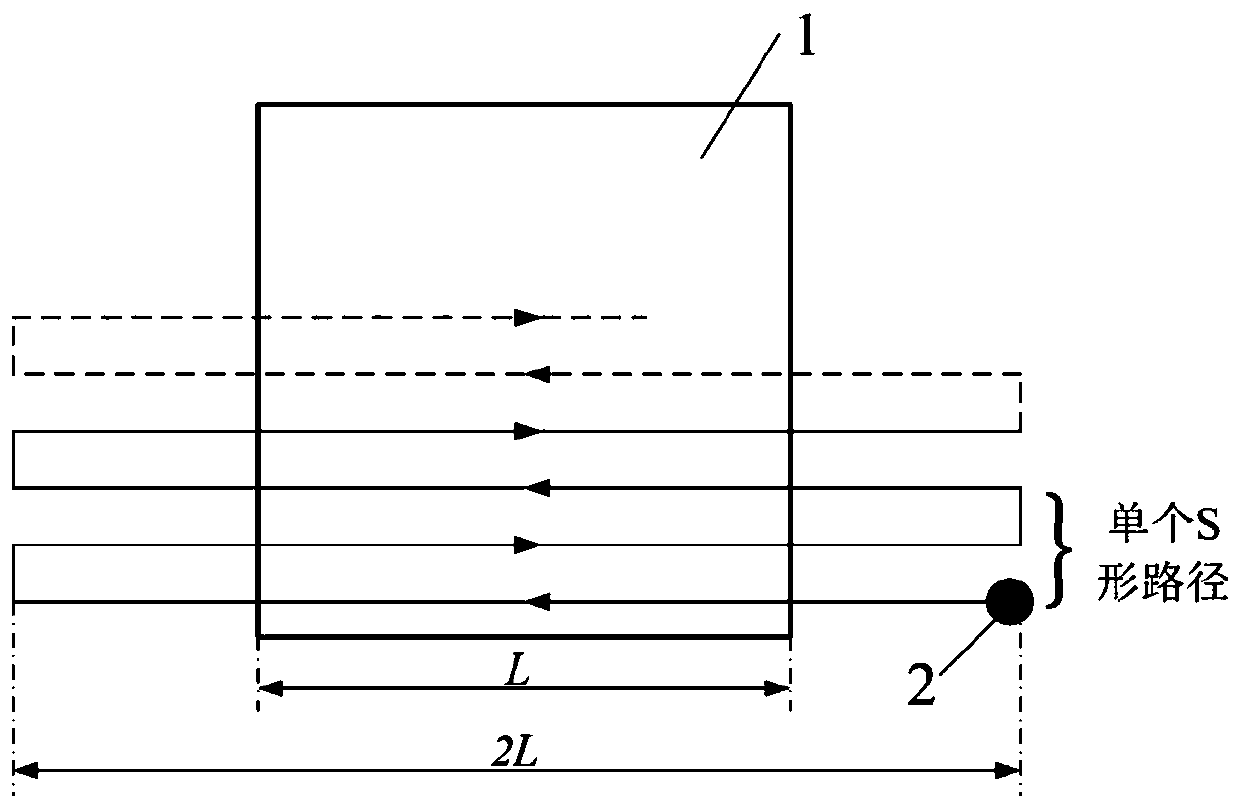

[0027] The process of ultrasonic rolling texturing is: in the continuous ultrasonic rolling process, the base metal moves a set distance along the -X direction, then moves a set distance along the +Y direction, and then moves a set distance along the +X direction , form an S-shaped tool path, and repeat the single S-shaped tool path at least once, so that the surface of the base metal is textured.

[0028] After research, the present invention found that when the surface of the base metal is textured by ultrasonic rolling, and then the AlCrN coating is prepared, the bonding force between the coating and the base can be signifi...

Embodiment 1

[0049] A preparation process of ultrasonic rolling textured AlCrN coating on the surface of a substrate. The substrate material is high-frequency quenched No. 45 steel, which is characterized in that micro-textures are produced by ultrasonic rolling on the surface of high-frequency quenched No. Textured surface deposition AlCrN coating, its preparation process, such as figure 1 As shown, the steps are as follows:

[0050] (1) Mechanically grind and polish the surface of the high-frequency quenching No. 45 steel substrate 1 to a surface roughness of Ra0.2 μm, and put it into alcohol and acetone solutions for ultrasonic cleaning for 15 minutes, and then dry it with a hair dryer , the three-dimensional topography of the treated substrate surface is shown in Figure 4 as shown in (a);

[0051] (2) On the ultrasonic rolling machine tool, set the static pressure of ultrasonic rolling to 1000N, the amplitude to 5μm, the feed rate to 0.1mm / r, the number of rolling times to 1, and th...

Embodiment 2

[0055] A preparation process of ultrasonic rolling textured AlCrN coating on the surface of a substrate. The substrate material is titanium alloy TC4, which is characterized in that micro-textures are produced by ultrasonic rolling on the surface of the titanium alloy TC4 substrate, and then deposited on the textured surface AlCrN coating, its preparation process steps are as follows:

[0056] (1) The surface of the titanium alloy TC4 substrate 1 is mechanically ground and polished until the surface roughness is Ra 0.2 μm, and then placed in alcohol and acetone solutions for ultrasonic cleaning for 15 minutes, and then dried with a hair dryer;

[0057] (2) On the ultrasonic rolling machine tool, set the static pressure of ultrasonic rolling to 1500N, the amplitude to 7μm, the feed rate to 0.05mm / r, the number of rolling times to 1, and the diameter of the rolling ball 2 to be 12mm. Under the processing parameters, the micro-texture processing is realized by adjusting the movin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com