Quick connector

A connector, fast technology, applied in the direction of couplings, pipe joints, pipes/pipe joints/pipe fittings, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

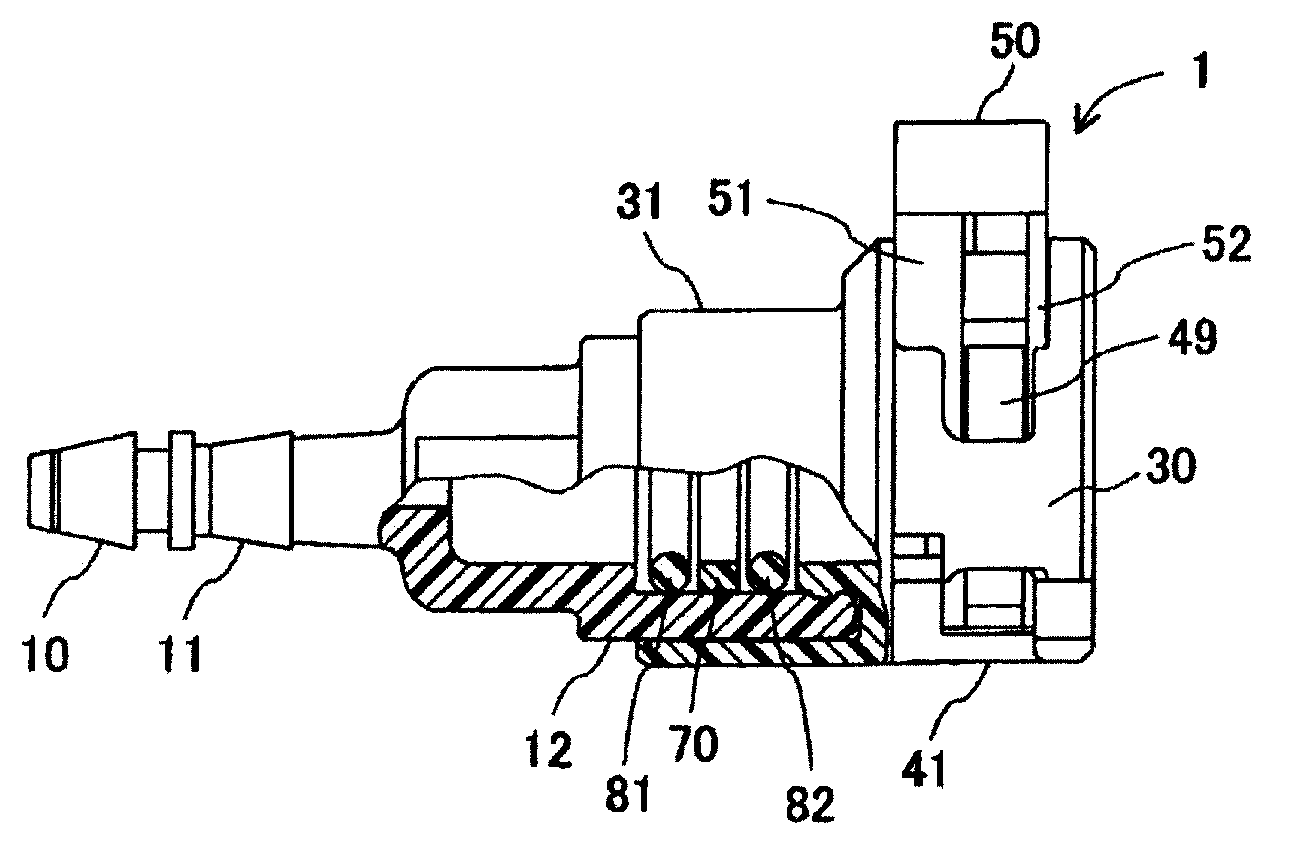

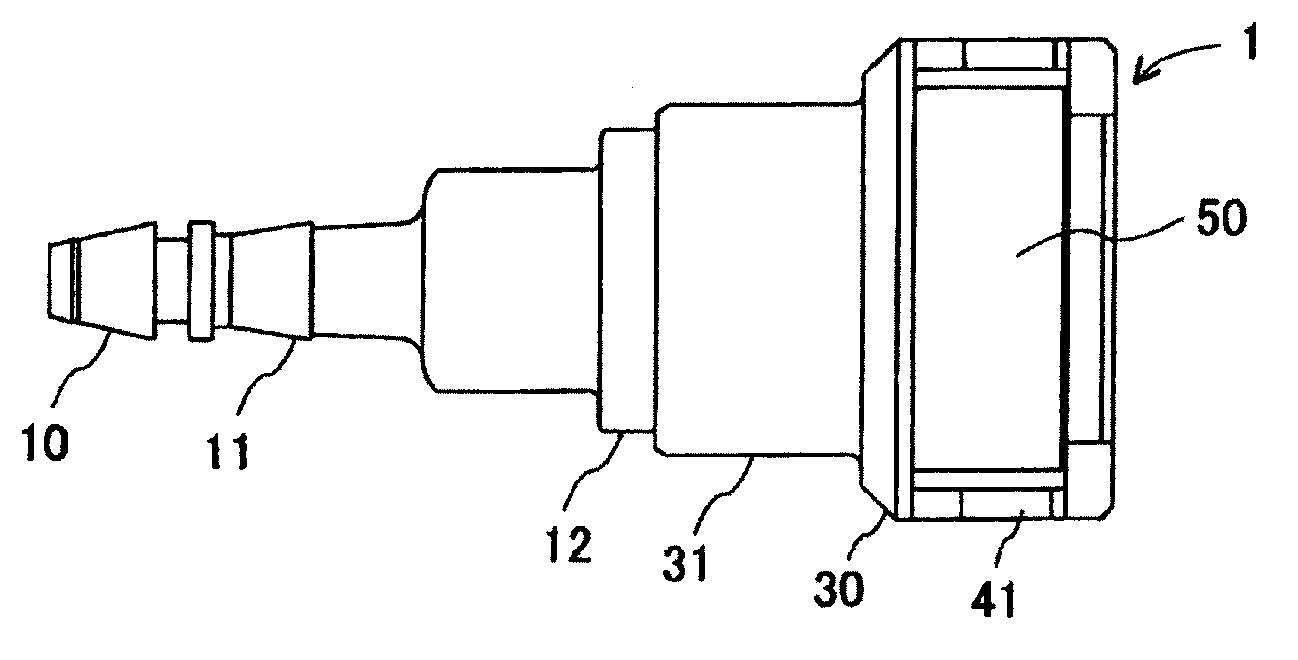

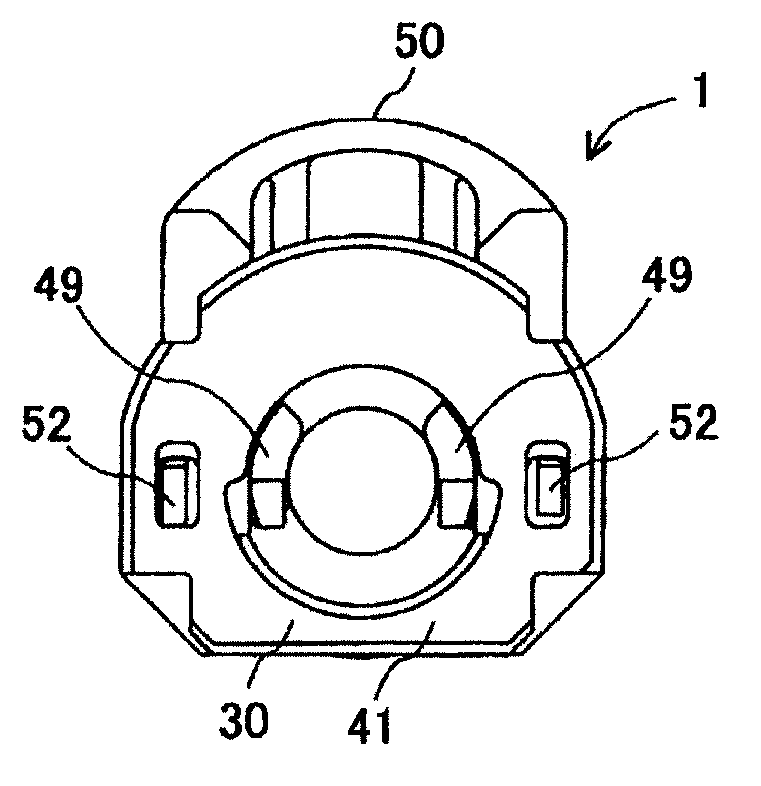

[0086] Overview of Quick Connectors

[0087] refer to Figure 1 ~ Figure 3 The outline of the quick connector 1 according to this embodiment will be described. like figure 1 As shown, the quick connector 1 is used to form, for example, gasoline fuel piping of an automobile. That is, the quick connector 1 forms a flow path through which, for example, fuel flows. One end side of the quick connector 1 ( figure 1 , figure 2 on the left side) is connected with the resin tube (not shown), the tube body 3 (such as Figure 23 shown) is inserted into the other end side of the quick connector 1 and connected with the other end side. That is, the quick connector 1 performs piping connection of the pipe body 3 and the resin pipe, and allows gasoline fuel to flow. The tube body 3 is formed in a cylindrical shape, and has an annular protrusion 3a (such as Figure 23 shown). The quick connector 1 includes a first housing 10 , a second housing 30 , a checker 50 , a collar 70 and a...

no. 2 approach

[0149] Next, the quick connector of the second embodiment will be described. The second housing and the checker of the quick connector of the second embodiment are different from the quick connector of the first embodiment. In addition, the mode in the locked confirmation state and when moving from the locked confirmed state to the released state is different from that of the first embodiment. The difference will be described below. In addition, the same code|symbol is attached|subjected to the same structure as 1st Embodiment, and description is abbreviate|omitted.

[0150] Detailed structure of the second shell

[0151] refer to Figure 38 ~ Figure 46 The detailed structure of the second housing 130 will be described. The second housing 130 includes a housing body part 131 and a holder part 141 . In addition, since the case main body portion 131 and the holder portion 141 are integrally formed, there is no strict boundary, but here, the Figure 38 The axis direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com