Laser additive manufacturing method of NiTi alloy with large recoverable strain

A laser additive and manufacturing method technology, applied in additive manufacturing, additive processing, metal processing equipment, etc., can solve the problems of low strain recovery rate of products or components, failure to meet the requirements of use, etc., and achieve excellent superelastic recovery performance and shape memory effect, no macroscopic cracks, large forming process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The first step: NiTi alloy powder particle size ranges from 50 μm to 150 μm, and is prepared by electrode induction gas atomization technology. The NiTi alloy powder is dried in a vacuum (≤0.1Pa) environment at 120°C for 2 hours, cooled to room temperature, taken out and put into a powder feeder.

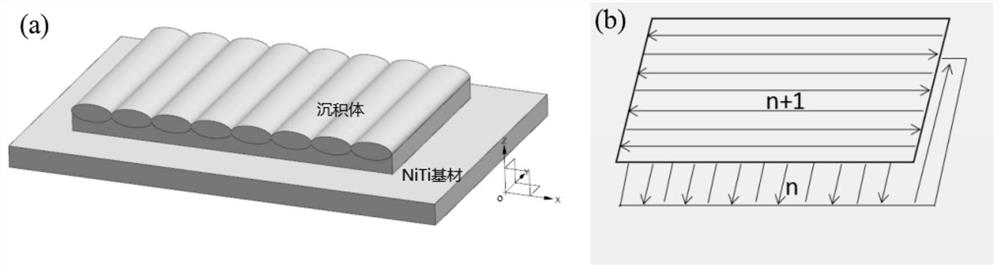

[0034] Step 2: Place and fix a NiTi alloy substrate with a size of 120mm×120mm×10mm in the forming chamber. Under the circulation of high-purity argon, the oxygen content of the atmosphere in the forming chamber is within 100ppm, and the forming starts.

[0035] Step 3: Turn on the laserline LDF6000 semiconductor laser, select a spot diameter of 3mm, and start to operate with a laser power of 1200W and a scanning rate of 800mm / min under the control of the CNC workbench, using high-purity argon as the powder delivery of the powder-carrying airflow The device sends the NiTi alloy powder to the NiTi alloy substrate for deposition at a powder feeding rate of 11.5g / min. The overla...

Embodiment 2

[0039] The first step: NiTi alloy powder particle size ranges from 50 μm to 150 μm, and is prepared by electrode induction gas atomization technology. The NiTi alloy powder is dried in a vacuum (≤0.1Pa) environment at 110°C for 2 hours, cooled to room temperature, taken out and put into a powder feeder.

[0040] Step 2: Place and fix a NiTi alloy substrate with a size of 120mm×120mm×10mm in the forming chamber. Under the circulation of high-purity argon, the oxygen content of the atmosphere in the forming chamber is within 100ppm, and the forming starts.

[0041] Step 3: Turn on the CP4000 CO 2 The laser, with a spot diameter of 2 mm, starts to operate with a laser power of 1500 W and a scanning rate of 800 mm / min under the control of a numerical control workbench. High-purity argon is used as the powder feeding device for the powder-carrying air flow to feed NiTi at a powder feeding rate of 11 g / min. The alloy powder is sent to the NiTi substrate for deposition, and the over...

Embodiment 3

[0044] The first step: NiTi alloy powder particle size ranges from 50 μm to 150 μm, and is prepared by electrode induction gas atomization technology. The NiTi alloy powder is dried in a vacuum (≤0.1Pa) environment at 120°C for 2 hours, cooled to room temperature, taken out and put into a powder feeder.

[0045] Step 2: Place and fix a NiTi alloy substrate with a size of 120mm×120mm×10mm in the forming chamber. Under the circulation of high-purity argon, the oxygen content of the atmosphere in the forming chamber is within 100ppm, and the forming starts.

[0046] Step 3: Turn on the CP4000 CO 2 The laser, with a spot diameter of 2 mm, starts to operate with a laser power of 1700 W and a scanning rate of 680 mm / min under the control of a numerical control workbench. High-purity argon is used as the powder feeding device for the powder-carrying air flow to feed NiTi at a powder feeding rate of 9 g / min. The alloy powder is sent to the NiTi substrate for deposition, and the overl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com