Method for preparing shape memory polyurethane resin

A polyurethane resin and memory technology, which is applied in the field of preparation of functional polymer materials, can solve the problems such as the mechanical properties and phase change energy storage properties of materials that are not discussed, and achieve excellent shape memory effect, outstanding shape memory effect, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 11.6g dehydrated molecular weight is 10000 polyethylene glycol, 6.6g dehydrated polyethylene glycol with 6000 molecular weight, 17.5g dehydrated polybutylene adipate glycol with 3000 molecular weight and 11.6g Diphenylmethane-4,4'-diisocyanate was mixed uniformly in the reactor and then prepolymerized at 25°C for 3 minutes; then 3.4g of 1,4-butanediol was added, stirred evenly and poured into the mold, at 70 chain extension reaction at 120°C for 20 hours; then aging at 120°C for 2 to 2.5 hours to obtain a shape-memory polyurethane resin.

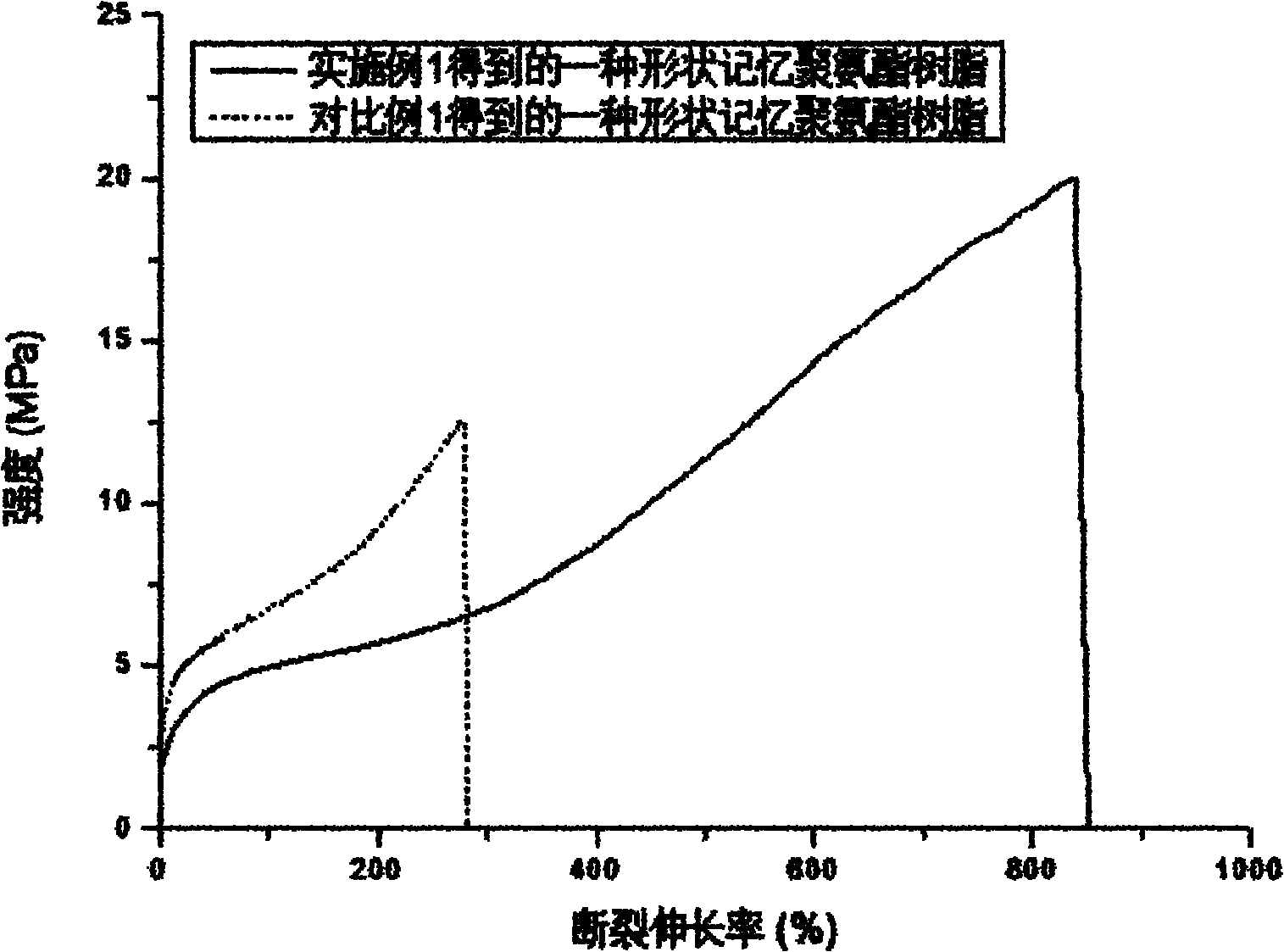

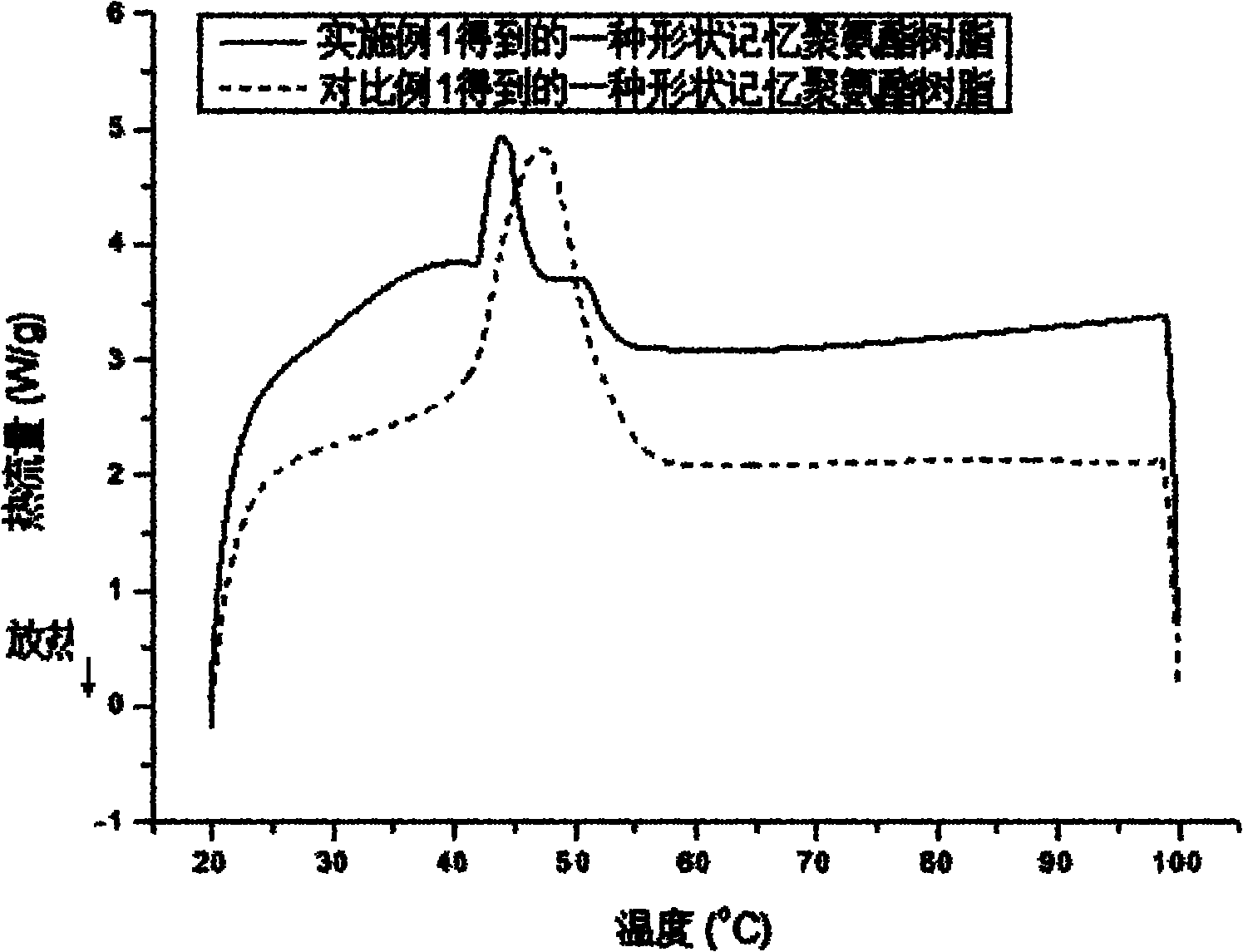

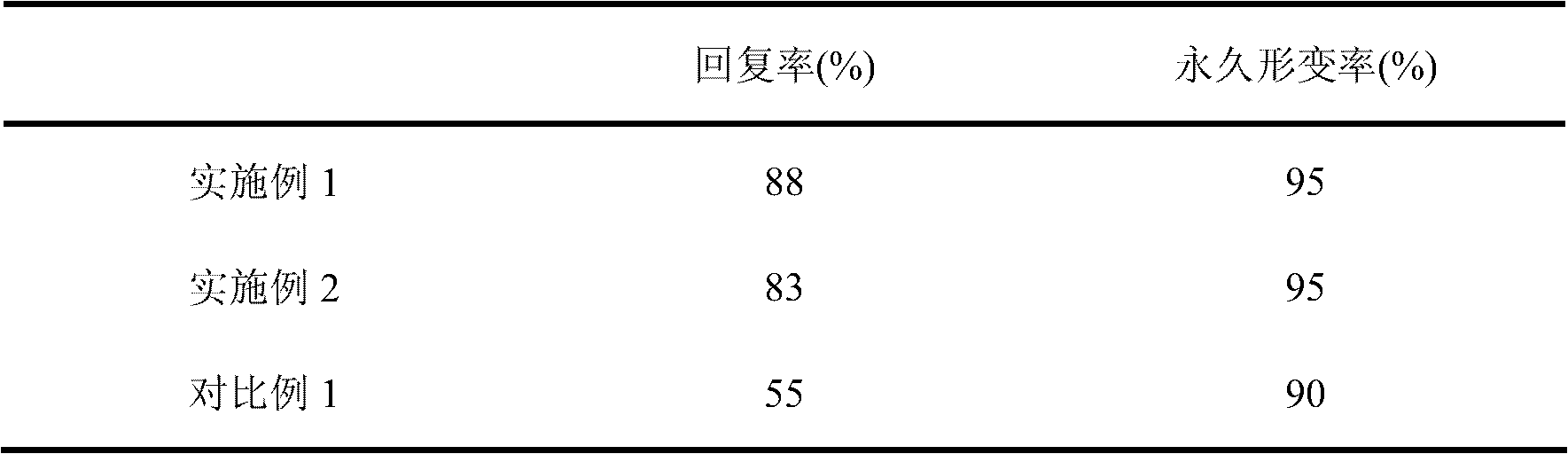

[0029]A kind of shape-memory polyurethane resin obtained in this embodiment is a kind of shape-memory polyurethane resin containing different molecular weight polyethylene glycols and polyester diols, which can be obtained from Table 1. The shape-memory recovery rate of this polyurethane can reach 88%, and the permanent The deformation rate can reach 95%, showing a good shape memory effect. Depend on figure 1 It can be obtained that...

Embodiment 2

[0031] 13.1g dehydrated molecular weight polyethylene glycol of 10000, 7.9g dehydrated polyethylene glycol of 6000 molecular weight, 17.5g dehydrated polybutylene adipate diol of 3000 molecular weight and 11.7g Diphenylmethane-4,4'-diisocyanate was mixed uniformly in the reactor and then prepolymerized at 20°C for 3 minutes; then 3.4g of 1,4-butanediol was added, stirred evenly and poured into the mold, at 70 chain extension reaction at 120°C for 20 hours; then aging at 120°C for 2 to 2.5 hours to obtain a shape-memory polyurethane resin.

[0032] A kind of shape-memory polyurethane resin that this embodiment obtains is a kind of shape-memory polyurethane resin that contains different molecular weight polyethylene glycols and polyester diols, and tensile stress-strain test records that the tensile strength of this resin is 13MPa, and elongation at break is 640%. The phase transition enthalpy of the resin measured by differential scanning calorimetry was 26 J / g, and the phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com