Method for improving shape memory effect of metastable austenitic stainless steel

A metastable austenite and memory effect technology, applied in the field of austenitic stainless steel, can solve problems such as poor memory effect, achieve the effect of improving shape memory effect and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

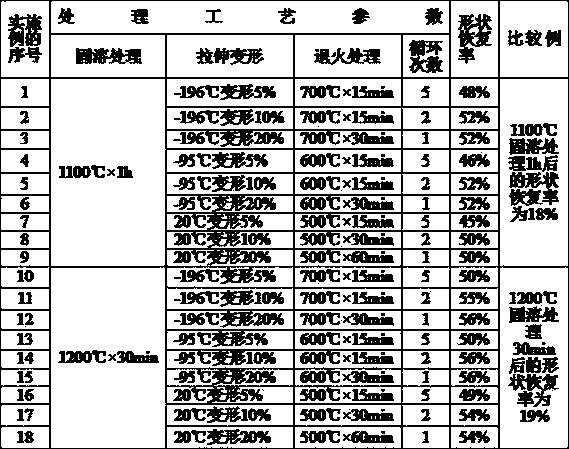

Embodiment 1~18

[0015] Commercial AISI304 stainless steel plate by weight percentage content of each element is as follows: Cr 18.12%, Ni 8.16%, Mn 1.51%, Si 0.53%, Cu 0.04%, V 0.11%, C 0.04%, the remainder is Fe and unavoidable Impurities. by formula M d =580-520C-2Si-16Mn-16Cr-23Ni-300N-26Cu-10Mo Calculate the maximum temperature M of its deformation-induced α′ martensite transformation d It is equal to 55.34°C and higher than -196°C, so the tensile deformation temperature range of this alloy is -196°C~55.34°C. The specific treatment process is as follows: first, the plate is subjected to solution treatment, and then stretched and deformed at different temperatures with different deformation amounts, followed by annealing treatment, and the above process of stretching deformation and annealing is cycled 1 to 5 times. The shape memory effect of the material is tested by bending deformation method: the sample is first deformed by 2% under liquid nitrogen, and then heated at 600°C for 5 minu...

Embodiment 19~27

[0020] Forged commercial AISI304 stainless steel by weight percentage content of each element is as follows: Cr 18.63%, Ni 8.77%, Mn 1.46%, Si 0.46%, Cu 0.05%, V 0.12%, C 0.05%, the rest is Fe and unavoidable of impurities. by formula M d =580-520C-2Si-16Mn-16Cr-23Ni-300N-26Cu-10Mo Calculate the maximum temperature M of its deformation-induced α′ martensite transformation d It is equal to 28.63°C and higher than -196°C, so the rolling deformation temperature range of this alloy is -196°C~28.63°C. The specific treatment process is as follows: first, the alloy is subjected to solution treatment, then rolled and deformed at 20°C with different deformations, and then annealed, and the above-mentioned rolling deformation plus annealing process is cycled 1 to 2 times. The shape memory effect of the material is tested by bending deformation method: the sample is first deformed by 2% under liquid nitrogen, and then heated at 600°C for 5 minutes to recover. The specific processing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com