Shape memory alloy reinforced magnesium-based composite material with three-dimensional interpenetrating network structure and preparation method thereof

A technology of interpenetrating network structure and memory alloy, which is applied in the field of magnesium-based composite materials and its preparation, can solve the problems that the mechanical properties of materials cannot be effectively regulated, the damage is difficult to automatically repair, and the original shape cannot be restored, so as to achieve the realization of structure and mechanics. Performance, Enhanced Coordination, Reduced Stress Concentration Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this example, a titanium-nickel alloy reinforced magnesium-based composite material with a three-dimensional interpenetrating network structure was prepared. The raw materials used include titanium-nickel alloy powder (the average particle size is 15 μm, and the atomic ratio of titanium to nickel is 1:1), and metal magnesium. Concrete preparation process is as follows:

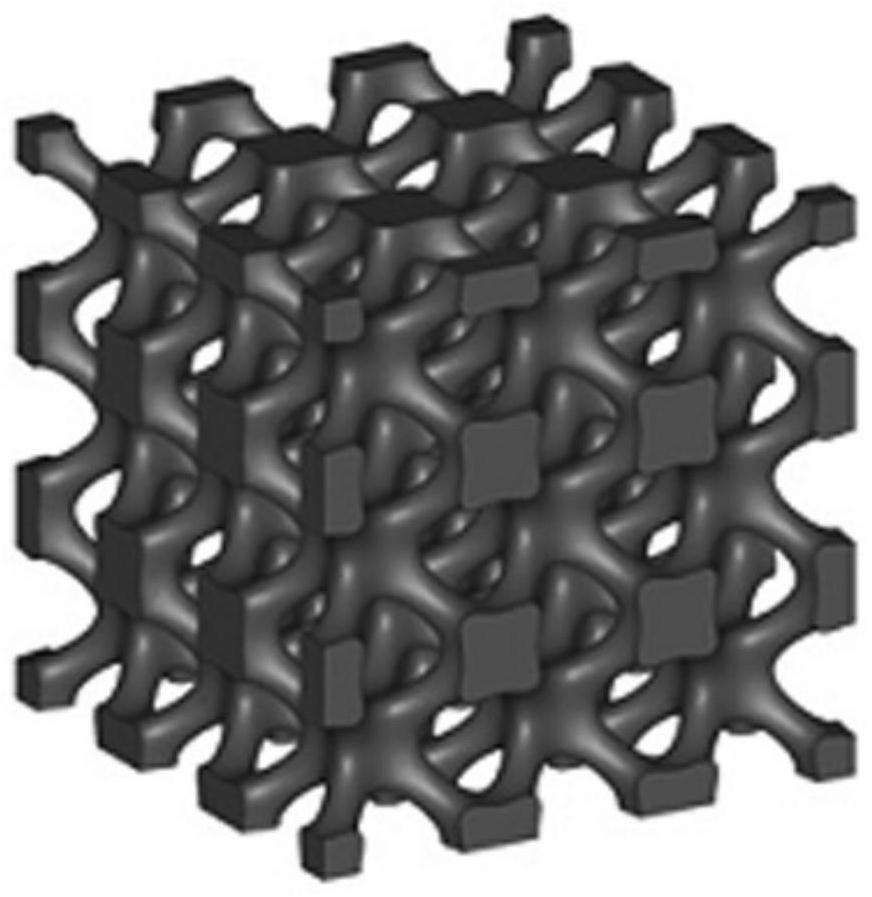

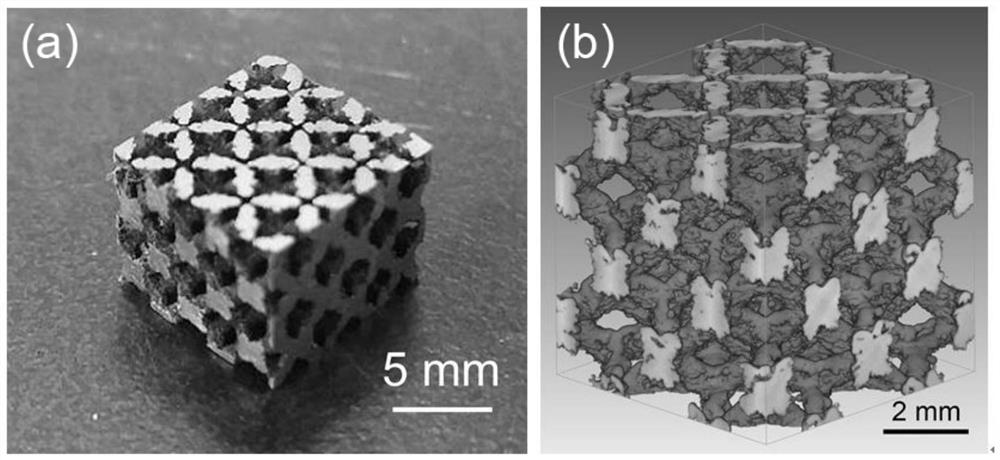

[0035] 1) Use the 3D visualization solid simulation software Autodesk Inventor Professional (AIP2019) to design a titanium-nickel alloy reinforcement skeleton with a network topology, and establish a 3D model of the skeleton. Such as figure 1As shown, the network topology of the model is established based on the principle of triple periodic minimum surface; the model is imported into the Realizer SLM 100 metal 3D printer formed by laser selective melting technology, and the titanium-nickel alloy is 3D printed under the protection of argon. The powder is prepared into a titanium-nickel alloy reinfor...

Embodiment 2

[0040] In this example, a titanium-nickel alloy reinforced magnesium alloy-based composite material with a three-dimensional interpenetrating network structure was prepared. The raw materials used include titanium-nickel alloy powder (the average particle size is 15 μm, the atomic ratio of titanium to nickel is 1:1), and AZ91D magnesium alloy. Concrete preparation process is as follows:

[0041] 1) This step is the same as step 1) in Example 1;

[0042] 2) The difference between this step and step 2) in Example 1 is that the metal used for infiltrating the nickel-titanium alloy skeleton is AZ91D magnesium alloy, and the infiltration temperature is 860°C;

[0043] 3) This step is the same as step 3) in Example 1.

[0044] After testing, the density of the composite material is 3.4g / cm 3 , the compressive strength is 400MPa, and the compressive plastic strain exceeds 30%. In addition, the composite material has a shape memory effect. When the compressive strain at room tempe...

Embodiment 3

[0046] In this example, a titanium-nickel alloy reinforced magnesium-based composite material with a three-dimensional interpenetrating network structure was prepared. The raw materials used include titanium-nickel alloy powder (the average particle size is 15 μm, and the atomic ratio of titanium to nickel is 1:1), and metal magnesium. Concrete preparation process is as follows:

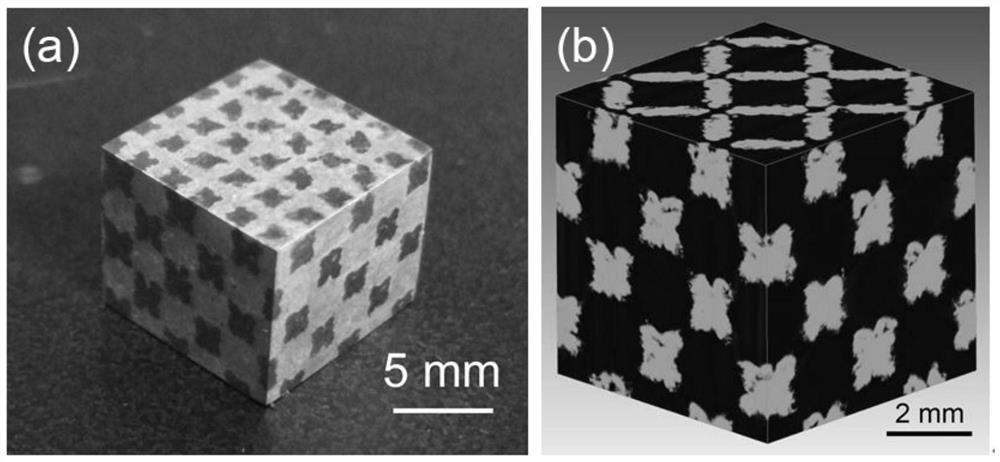

[0047] 1) This step is similar to step 1) in Example 1, the difference is that the 3D printed titanium-nickel alloy skeleton structure is different, see Figure 5 .

[0048] 2) This step is the same as step 2) in Example 1;

[0049] 3) This step is similar to step 3) in Example 1, except that the volume fraction of the titanium-nickel alloy reinforcement in the composite material is 64%.

[0050] After testing, the density of the composite material is 4.1g / cm 3 , the compressive strength is 590MPa, and the compressive plastic strain exceeds 25%. In addition, the composite material has a shape me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com