Intrinsic conduction shape memory polymer and preparation method thereof

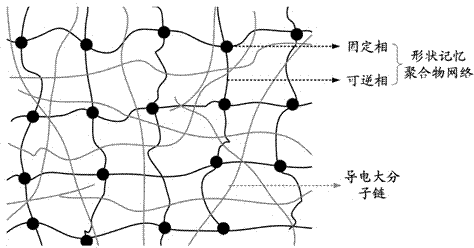

A memory polymer and intrinsically conductive technology, which is applied in the field of multifunctional polymer materials, can solve the problems that shape memory polymers do not have conductive function and limitations, and achieve large deformation of shape memory effect, low cost and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

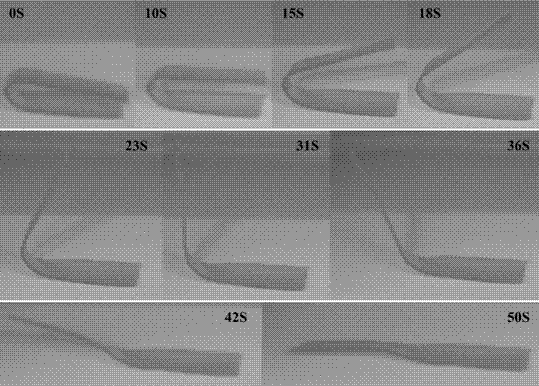

Examples

Embodiment 1

[0025] Embodiment one: The intrinsic conductive shape memory polymer comprises 100 parts of shape memory epoxy polymer and 30 parts of conductive polyaniline by weight.

[0026] The composition of the shape memory epoxy polymer in this embodiment is 100 parts of bisphenol A epoxy resin and 100 parts of amine curing agent diethylenetriamine.

[0027] The conductive polyaniline is composed of 100 parts of aniline monomer, 1000 parts of dopant dodecylbenzenesulfonic acid (DBSA) and 150 parts of oxidant ammonium persulfate.

[0028] The preparation method of the intrinsically conductive shape memory polymer is as follows:

[0029] 1. Mix the aniline monomer and the dopant DBSA in parts by weight, and stir evenly; add the oxidant ammonium persulfate in parts by weight to the mixture at 0-10°C, stir at a constant temperature for 0.5-2 hours, and then perform ultrasonic Process to obtain the emulsion; 2. Add amine curing agent diethylenetriamine and bisphenol A epoxy resin to the ...

Embodiment 2

[0031] Embodiment two: The intrinsic conductive shape memory polymer comprises 100 parts of shape memory epoxy polymer and 40 parts of conductive polyaniline by weight.

[0032] The composition of the shape memory epoxy polymer consists of 100 parts of aliphatic glycidyl ether resin (polypropylene glycol diglycidyl ether) and 85 parts of amine curing agent (m-phenylenediamine) by weight.

[0033] The conductive polyaniline is composed of 100 parts of aniline derivative (diphenylamine), 1200 parts of p-toluenesulfonic acid and 120 parts of potassium dichromate by weight.

[0034] The preparation method of the intrinsically conductive shape memory polymer is as follows:

[0035] 1. Mix diphenylamine and toluene sulfonic acid in parts by weight and stir evenly; add potassium dichromate in parts by weight to the mixture at 0~10°C, stir at constant temperature for 0.5~2h, and then perform ultrasonic Process to obtain the emulsion; 2. Add polypropylene glycol diglycidyl ether and...

Embodiment 3

[0037] Embodiment three: The intrinsic conductive shape memory polymer comprises 100 parts of shape memory epoxy polymer and 50 parts of conductive polyaniline by weight.

[0038] The epoxy shape memory polymer comprises 100 parts of cycloaliphatic epoxy resin ERL-4289, 70 parts of anhydride curing agent and 5 parts of accelerator isobutanol according to the mass fraction ratio;

[0039] The conductive polyaniline is prepared by including 100 parts of aniline monomer, 900 parts of sulfosalicylic acid and 110 parts of oxidant iodine according to the mass fraction ratio.

[0040] The preparation method of the intrinsically conductive shape memory polymer is as follows: 1. Mix the aniline monomer and sulfosalicylic acid in parts by weight, and stir evenly; Iodine; after stirring at constant temperature for 0.5~2h evenly, perform ultrasonic treatment to obtain the emulsion; 2. Add aliphatic epoxy resin ERL-4289 and tetrahydrophthalic anhydride curing agent to the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com