Shape memory material based on polylactic acid, manufacturing and using process thereof

A memory material, polylactic acid technology, applied in the field of shape memory materials, can solve the problems of low toughness of polylactic acid, limited application scope, etc., and achieve the effects of high toughness, elongation at break, and good shape memory effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] HYBRANE PS2550 from DSM Company was selected, blended with polylactic acid (molecular weight: 200,000) at a mass ratio of 2.5% in a Harker blender. The blending temperature is 180° C., the screw speed is 50 r / min, and the blending time is 5 minutes.

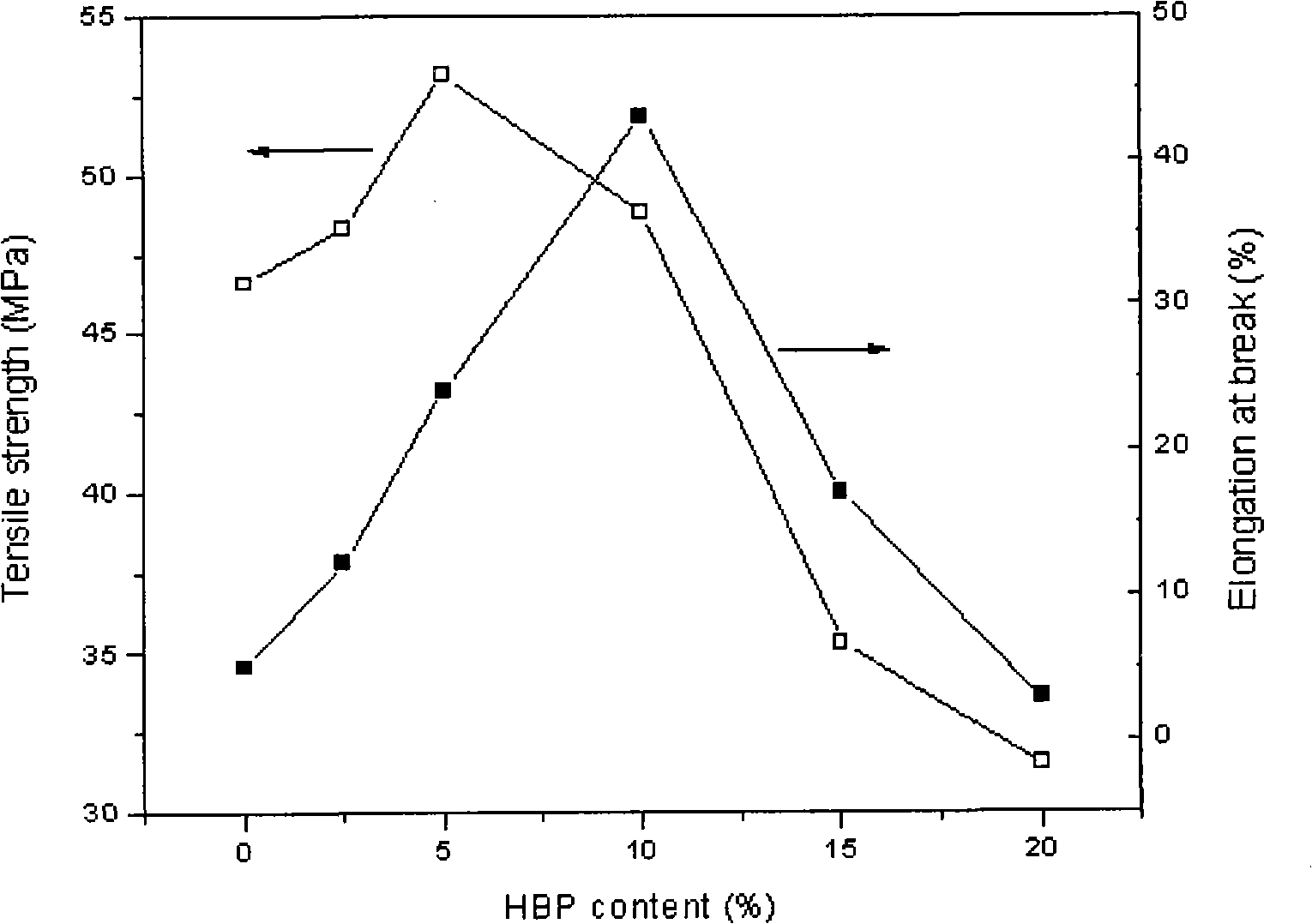

[0032] The blend was injection molded at 175°C to make a dumbbell-shaped mechanical spline with a thickness of 1 mm and a length of 8 cm. Then the blend was placed at 110° C. for about 30 minutes to crystallize and set. The tensile strength is 48.31MPa, the elongation at break is 12.11%, and the degree of recovery is 98%.

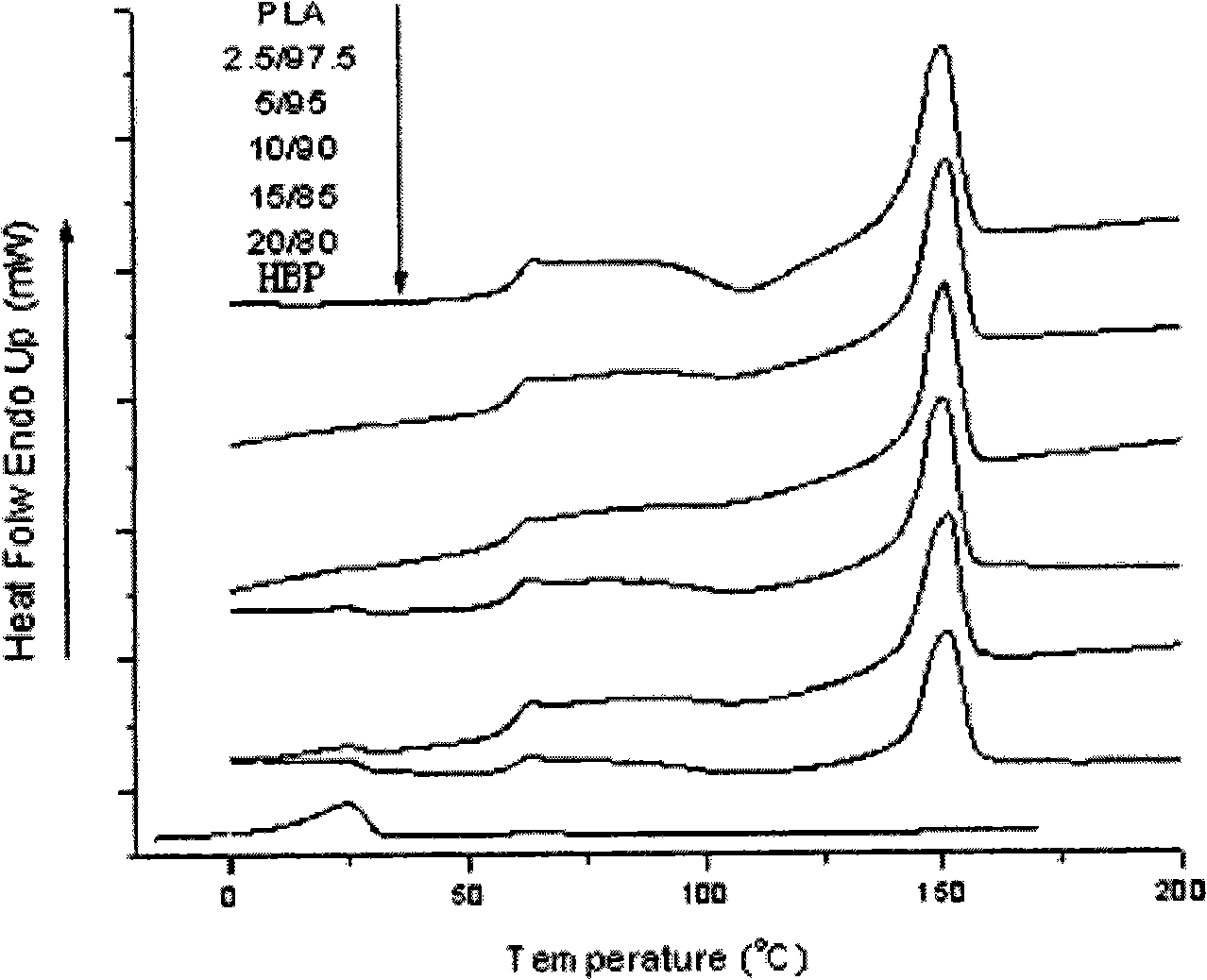

[0033] For thermal performance curves see figure 2 , see mechanical properties image 3 .

Embodiment 2

[0035] The selected HYBRANE PS2550 of DSM Company was blended with polylactic acid (molecular weight 80000) at 5% by mass in a Haake blender. The blending temperature is 180° C., the screw speed is 50 r / min, and the blending time is 5 minutes.

[0036] The blend was injection molded at 175°C to make a dumbbell-shaped mechanical spline with a thickness of 1 mm and a length of 8 cm. Then the blend was placed at 110° C. for about 30 minutes to crystallize and set. The tensile strength is 53.17MPa, the elongation at break is 24.01%, and the degree of recovery is 96%.

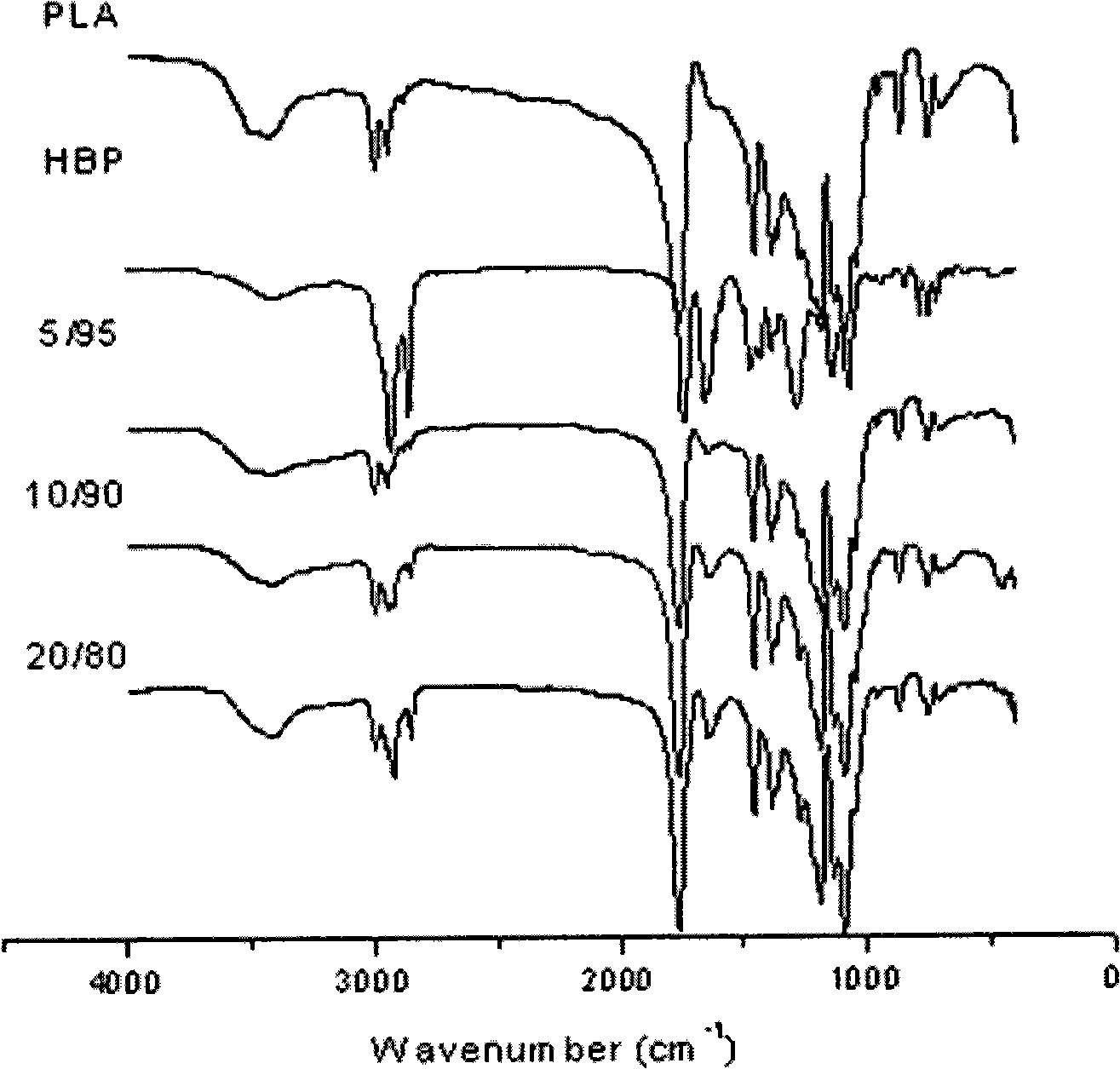

[0037] Infrared spectrum see figure 1 , thermal performance curve see figure 2 , see mechanical properties image 3 , shape memory effect see Figure 4 .

Embodiment 3

[0039] HYBRANE PS2550 from DSM Company was selected, blended with polylactic acid (molecular weight 120,000) at 10% by mass in a Haake blender. The blending temperature is 180° C., the screw speed is 50 r / min, and the blending time is 5 minutes.

[0040] The blend was injection molded at 175°C to make a dumbbell-shaped mechanical spline with a thickness of 1 mm and a length of 8 cm. Then the blend was placed at 110° C. for about 30 minutes to crystallize and set. The tensile strength is 48.81MPa, the elongation at break is 43.06%, and the degree of recovery is 94%.

[0041] Infrared spectrum see figure 1 , thermal performance curve see figure 2 , see mechanical properties image 3 , shape memory effect see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com