A kind of anti-abrasion epoxy resin mortar and preparation method thereof

An epoxy resin and anti-abrasion technology, which is applied in the field of hydraulic construction materials, can solve problems such as insufficient production process routes and insufficient toughness, and achieve excellent anti-abrasion performance and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of abrasion-resistant epoxy resin mortar described in each embodiment, comprises the steps:

[0033] (1) Epoxy resin, active diluent, ultra-high molecular weight polyethylene fiber and quartz sand are stirred evenly, and then packaged to obtain component A;

[0034] (2) After the curing agent is weighed, it is individually packaged to form component B;

[0035] (3) During construction, mix component A and component B evenly to obtain ultra-high molecular weight polyethylene fiber reinforced anti-impact epoxy mortar.

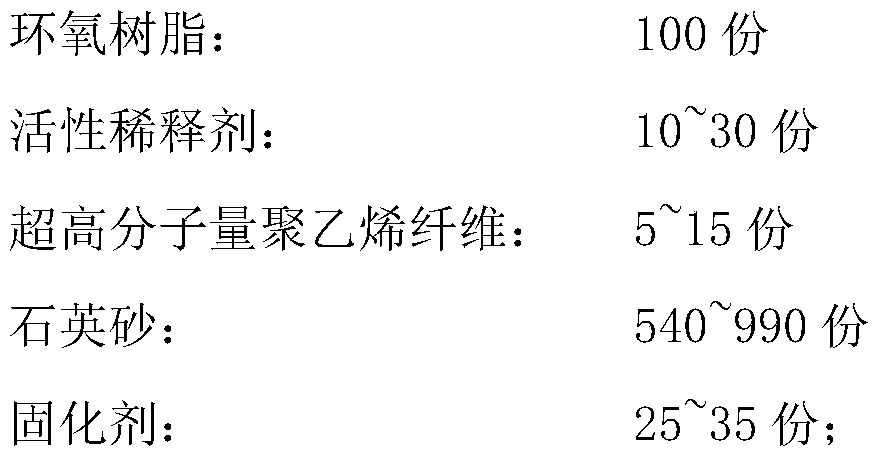

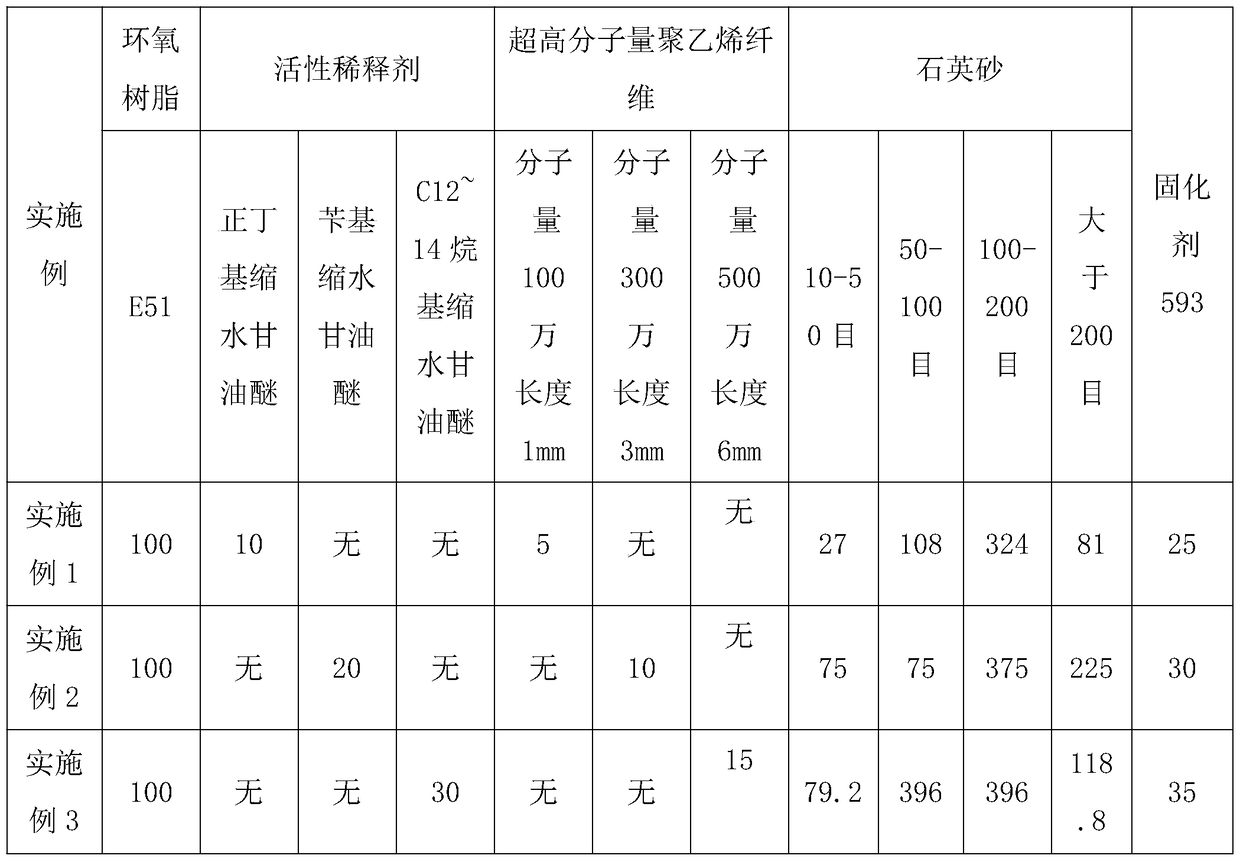

[0036] The formula ratio and performance data of each embodiment and comparative example are shown in Table 1 and Table 2.

[0037] Table 1 each embodiment and the raw material formula of comparative example

[0038]

[0039]

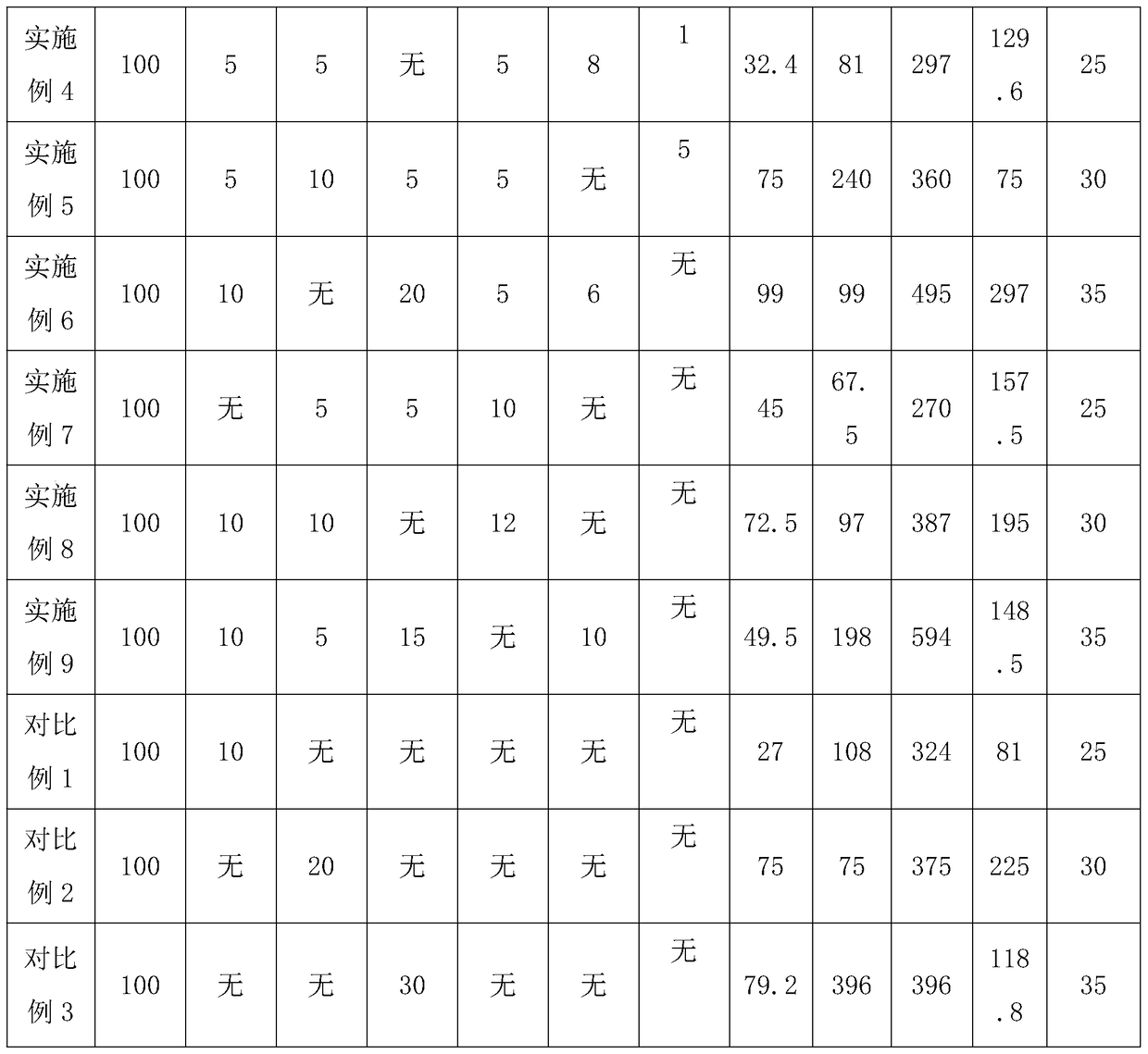

[0040] The epoxy resin mortar performance result that each embodiment of table 2 and comparative example make

[0041]

[0042]

[0043] Note: [1] The toughness of materials can be compared by u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com