Composite bipolar plate for fuel cell and its preparation method and application

A bipolar plate, polymer technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced bipolar plate cost, complex preparation process, low production efficiency, etc., to improve full battery performance and simple equipment requirements. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

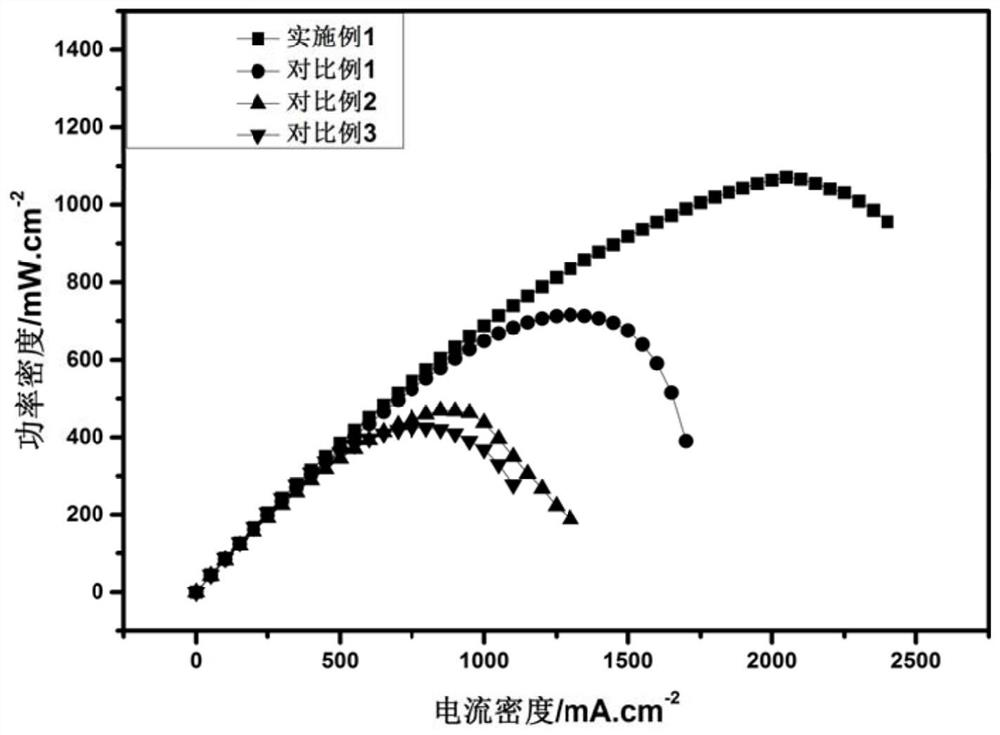

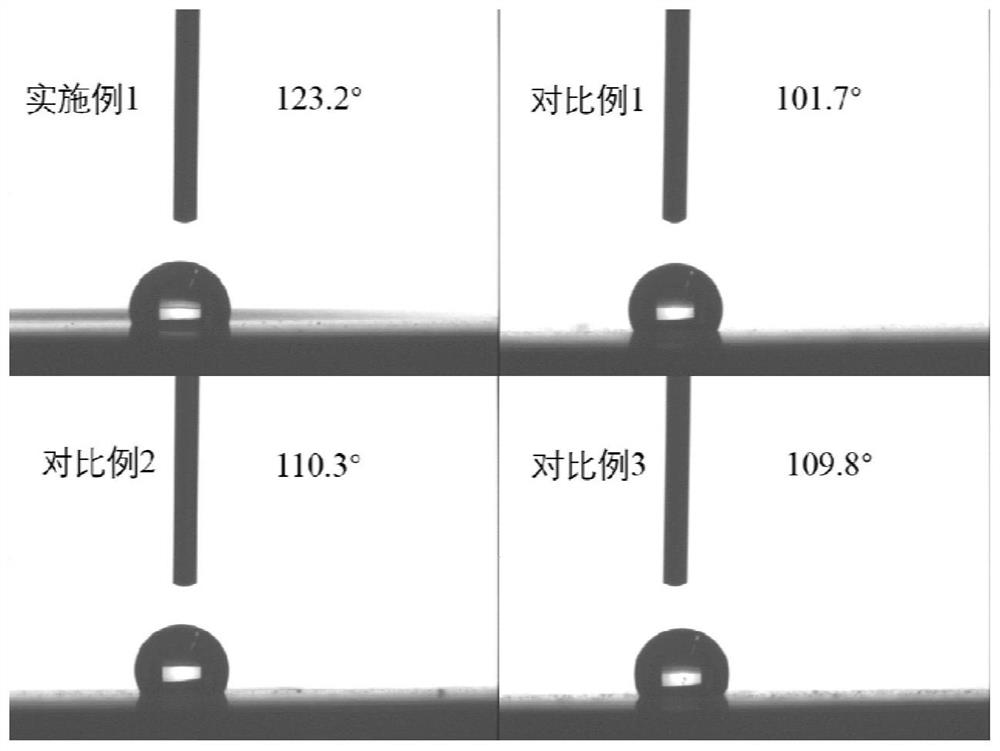

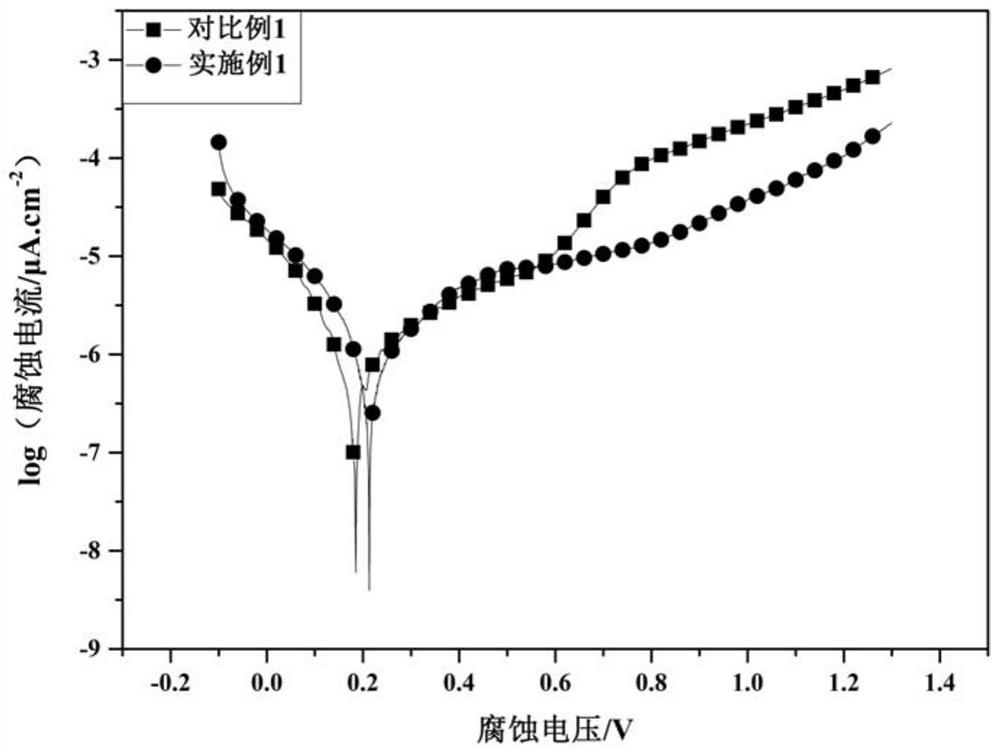

Embodiment 1

[0035] Take by weighing ABS resin (molecular weight is 500,000) 0.8kg, PVDF resin (molecular weight is 500,000) 0.8kg, graphite powder 8kg, carbon fiber 0.2kg, join in the kneader, kneading temperature is room temperature, kneading speed is 30r / min, kneading time 10min. Then the uniformly mixed material was transferred to a mold with a flow field, the pre-compression pressure was 40Mpa, the molding temperature was 160°C, the molding pressure was 80MPa, and the molding time was 5min. Finally, the cooling method of circulating water was used to lower the mold temperature to room temperature, and the carbon / polymer composite bipolar plate was obtained by releasing the pressure and demoulding.

Embodiment 2

[0037]Weigh ABS resin (molecular weight is 2 million) 0.6kg, PVDF resin (molecular weight is 1.5 million) 0.8kg, PP resin (molecular weight is 35,000) 0.1kg, graphite powder 8.5kg, carbon fiber 0.3kg respectively, add to kneading In the machine, the kneading temperature is room temperature, the kneading speed is 45r / min, and the kneading time is 15min. Then the uniformly mixed material was transferred to a mold with a flow field, the pre-compression pressure was 60MPa, the molding temperature was 180°C, the molding pressure was 100MPa, and the molding time was 15min. Finally, the temperature of the mold is lowered to room temperature by circulating water cooling, and the carbon / polymer composite bipolar plate is obtained by releasing the pressure and demoulding.

Embodiment 3

[0039] Weigh respectively ABS resin (molecular weight: 1 million) 0.4kg, PVDF resin (molecular weight: 2 million) 0.6kg, PP resin (molecular weight: 120,000) 0.3kg, graphite powder 9.0kg, carbon fiber 0.4kg, Add it into a kneader, the kneading temperature is room temperature, the kneading speed is 50r / min, and the kneading time is 30min. Then the uniformly mixed material was transferred to a mold with a flow field, the pre-compression pressure was 80MPa, the molding temperature was 200°C, the molding pressure was 120MPa, and the molding time was 25min. Finally, the cooling method of circulating water is used to lower the mold temperature to room temperature, and the carbon / polymer composite bipolar plate is obtained by releasing the pressure and demoulding;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com