Functionalized treatment method of Ti-V-Al light memory alloy for structural connection of aerospace non-metal-matrix composites

A composite material and structural connection technology, applied in the field of aerospace composite materials, can solve problems such as low shape memory effect, and achieve the effect of improving shape memory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] In this embodiment, the Ti-V-Al alloy is composed of three elements: Ti, V and Al, wherein the atomic number ratio of Ti is 84%, the atomic number ratio of V is 13%, and the atomic number ratio of Al is 3. %.

[0030] In this embodiment, the Ti-13V-3Al alloy is made of sponge titanium with a purity of 99.95wt.%, 99.99wt.% V, and 99.99wt.% Al as raw materials, and is melted in a non-consumable arc melting furnace. Draw up to 5×10 -3 Prepared after Pa. In order to ensure the uniformity of the alloy composition, each ingot was turned and smelted six times and magnetically stirred.

[0031] The smelted ingot weighs about 60g after mechanical polishing to remove surface impurities. The ingot was held at 900°C for 2 hours under vacuum to homogenize the alloy composition, and then quenched into water to form thermoelastic martensite.

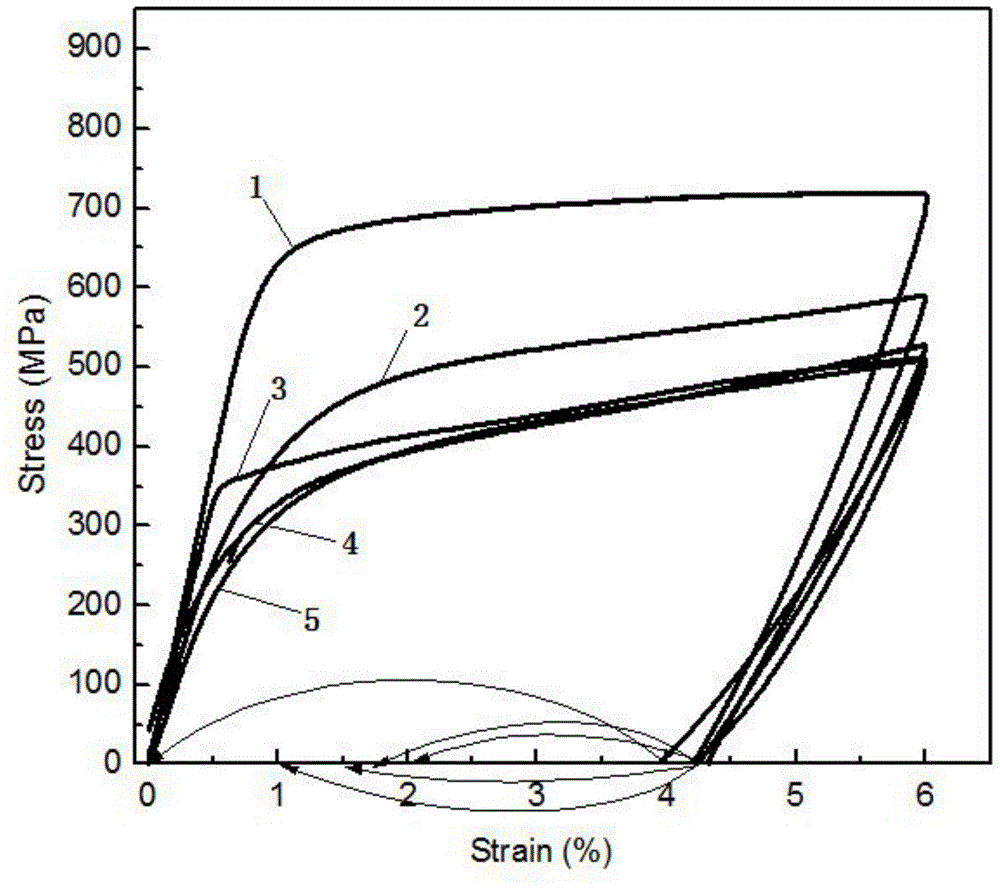

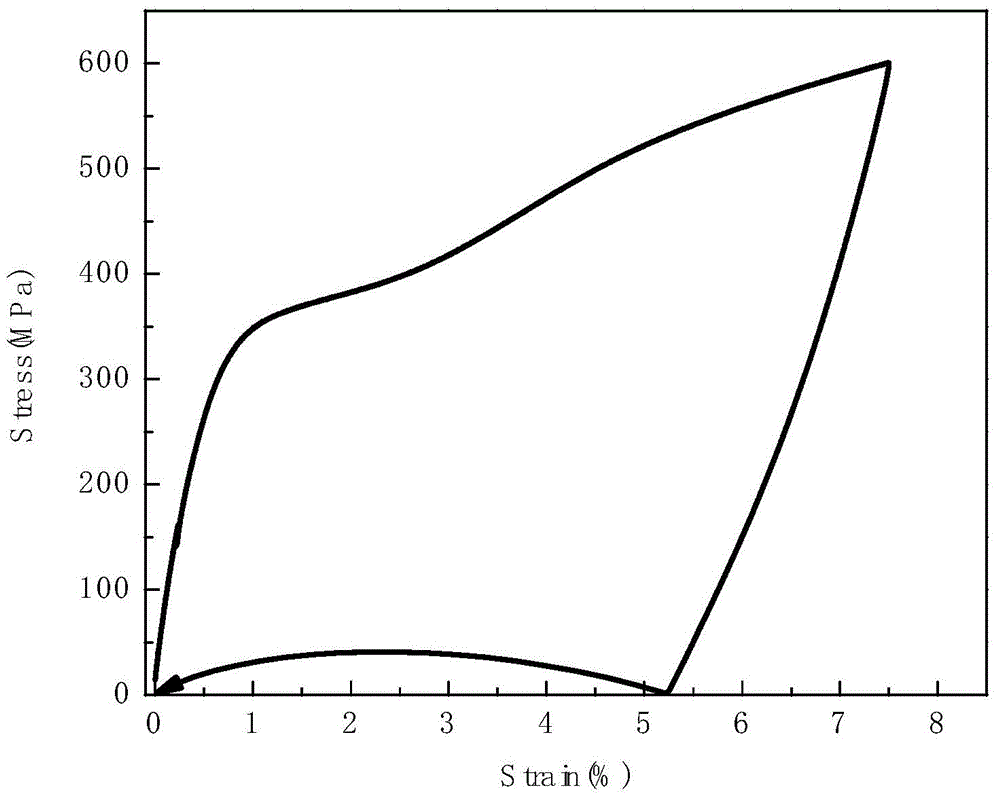

[0032] The heat-treated ingot is kept at 850° C. for half an hour and then hot-rolled, each down-rolling amount is 10%, and then returned t...

specific Embodiment approach 2

[0043] The difference between this embodiment and the first embodiment is that the tensile rate of the tensile test at room temperature is 3% / min.

specific Embodiment approach 3

[0045] The difference between this embodiment and specific embodiments 1 and 2 is that the solution treatment temperature is 850°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com