Shape memory ceramic and its prepn

A technology of memory ceramics and polycrystalline ceramics, applied in the field of shape memory ceramics, can solve the problems of incomplete shape recovery, small recoverable strain, etc., and achieve the effect of high operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In order to make the composition of 8mol% CeO 2 , 0.5mol% Y 2 o 3 and the balance is ZrO 2 The shape-memory ceramics were prepared by co-precipitation method to prepare ultra-fine powders of each component, sintered in air at 1500 ° C for 6 hours, and then gradually cooled.

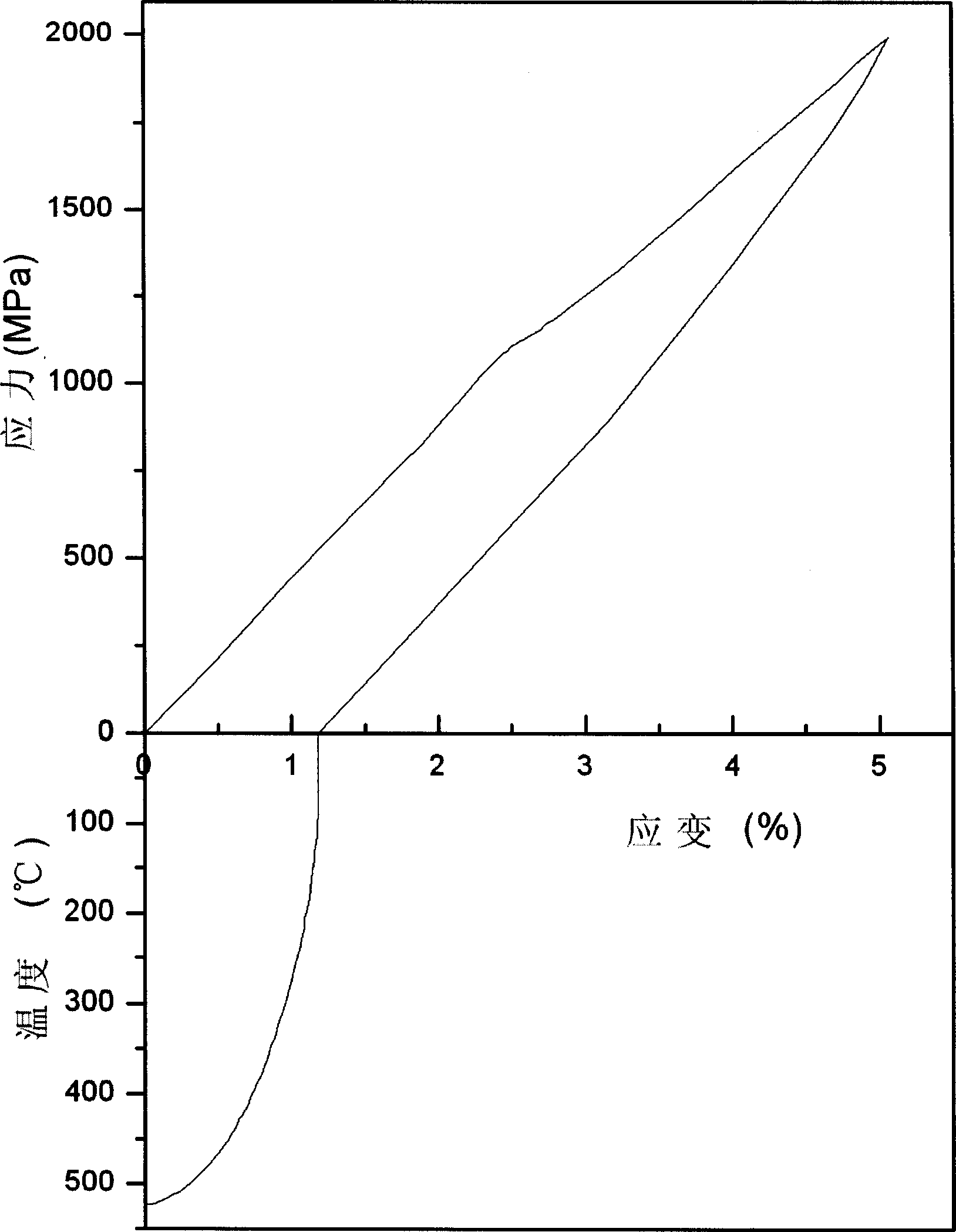

[0017] This method can be used to obtain an average grain size of 1.06μm and a density of 6.03g / cm 3 Tetragonal zirconia polycrystalline blocks, such as figure 1 shown. The test data of the recoverable strain and shape recovery rate of the polycrystalline ceramics are listed in Table 1, and the corresponding temperature-strain and stress-strain relationship curves made according to the above test data are shown in figure 2 . It can be seen from the test results that when the recoverable strain is 1.18%, the shape recovery rate is still 100%.

[0018] During the test, the length before compression of the sample is measured l 1 =6.974mm, length l after compression 0 =6.892, heat up to 600°C...

Embodiment 2

[0021] Using the same preparation and sintering method as in Example 1 to produce a composition of 7.5mol% CeO 2 , 0.45mol%Y 2 o 3 and the balance is ZrO 2 Shape-memory ceramics, the prepared tetragonal zirconia bulk material is tested by the same test method as in Example 1, and the recoverable strain is 1.2%, and the shape recovery rate is 100%.

Embodiment 3

[0023] Using the same preparation and sintering method as in Example 1 to produce a composition of 8.5mol% CeO 2 , 0.55mol% Y 2 o 3 and the balance is ZrO 2 Shape-memory ceramics, the prepared tetragonal zirconia bulk material is tested by the same test method as in Example 1, and the recoverable strain is 1.1%, and the shape recovery rate is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com