High heat stability ordered mesoporous aluminum phosphate material and its preparing method

A kind of aluminum phosphate, stable technology, applied in the direction of molecular sieve characteristic aluminum phosphate, molecular sieve and alkali-exchanged phosphate, phosphorus compounds, etc., can solve the problems of less extensive application, low thermal stability, etc. The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

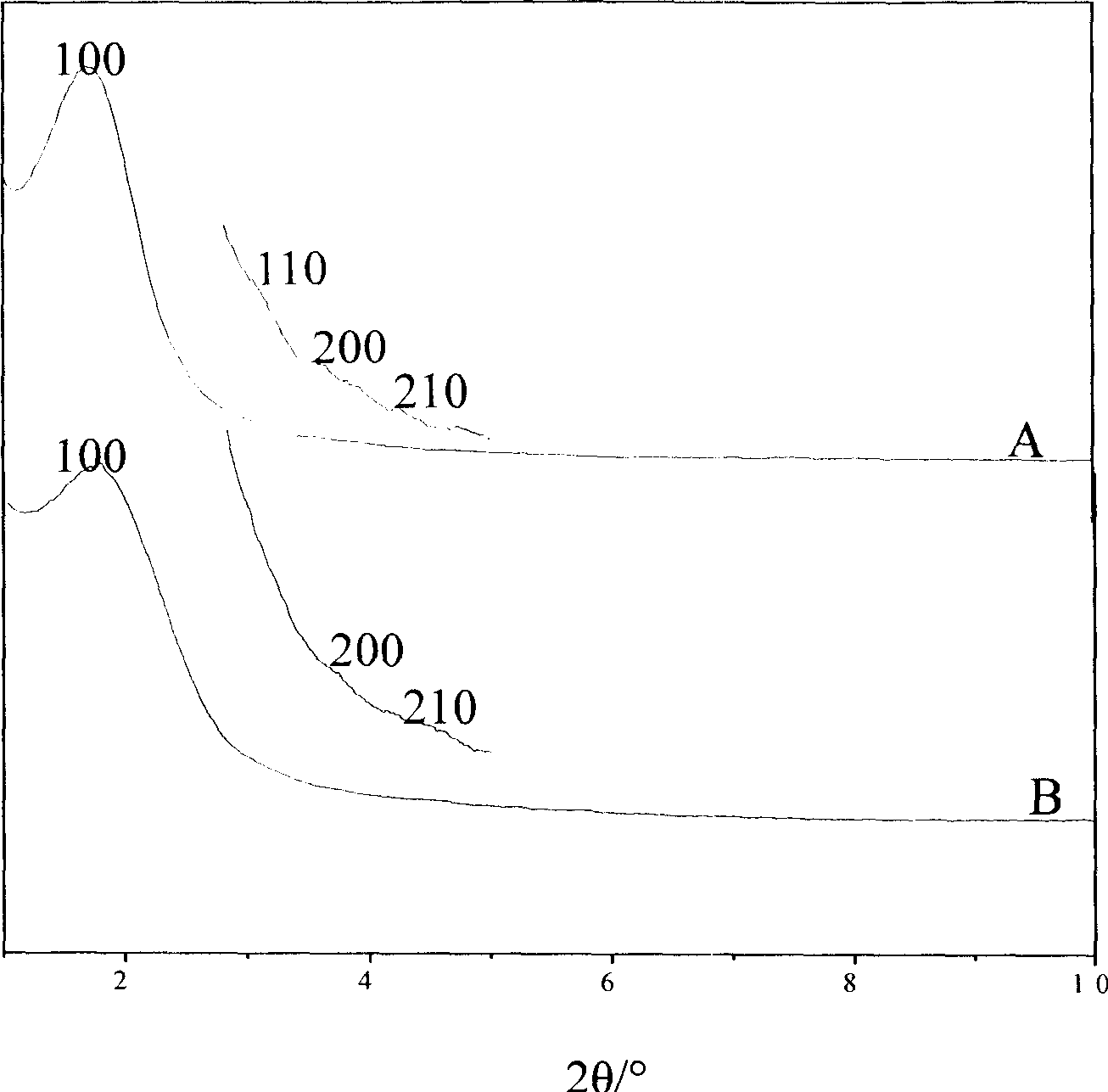

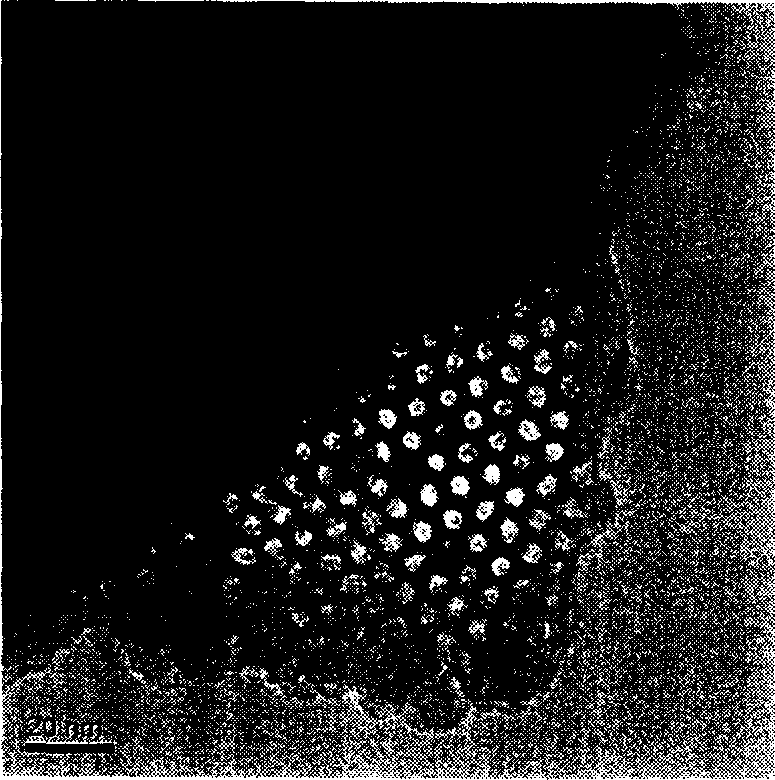

[0020] Example 1: Preparation of highly thermally stable ordered mesoporous aluminum phosphate

[0021] First, using aluminum isopropoxide as the aluminum source, phosphoric acid as the phosphorus source, and TEAOH as the template, a precursor solution containing the primary and secondary structural units of the microporous aluminum phosphate zeolite molecular sieve was synthesized. Stir the above three raw materials according to a certain ratio at room temperature to form a clear solution, then put it into a stainless steel reactor with a polytetrafluoroethylene liner and place it at 140°C for 3 hours. After the solution was taken out, it was still a clear solution. The specific ratio is as follows, Al 2 o 3 :xP 2 o 5 :m(TEA) 2 O:nH 2 O, here x=2~3.2, m=2.5~3.5, n=150~200.

[0022] Experiments have shown that as long as the temperature fluctuates up and down within 20°C and the static storage time does not exceed 1 hour in the stainless steel reactor, that is, in the r...

Embodiment 2

[0032] Example 2: Preparation of heteroatom-containing ordered mesoporous aluminum phosphate materials with high thermal stability

[0033] When preparing the precursor solution, that is, when synthesizing the microporous aluminum phosphate molecular sieve directing agent, use butyl titanate as the titanium source, use tetraethyl orthosilicate as the silicon source, and use iron sulfate and copper sulfate as the iron source and copper Source, prepared microporous aluminum phosphate molecular sieve guide agent containing various heteroatoms. Using the same raw material as in Example 1 and the same molar ratio range as in Example 1, the solution raw material consumption containing cations is Ti 4+ or Si 4+ or Fe 3+ or Cu 2+ with Al 2 o 3 The molar ratio is greater than 0 to 0.5. Process is also substantially the same as in Example 1. The prepared mesoporous aluminum phosphate material containing various heteroatoms. These samples were named Ti-JLU-50, Si-JLU-50, Cu-JLU-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com