Preparation method of L10-FePt granular film

A l10-fept, thin film technology, applied in ion implantation plating, metal material coating process, coating, etc., to achieve the effect of small magnetic interaction, lower ordering temperature, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0024] Specific Embodiment 2. This embodiment is a kind of L1 described in Specific Embodiment 1. 0 -The specific embodiment of the preparation method of FePt particle thin film:

[0025] 1. Substrate treatment: the substrate described in this embodiment is a Si(001) substrate, and the substrate is ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, and then sent into a vacuum chamber after drying;

[0026] 2. Deposition conditions: At room temperature, the ATC 1800-F multi-target magnetron sputtering system adopts DC co-sputtering, and the background vacuum of the sputtering system is better than 1.5×10 -4 Pa, the working pressure of Ar during sputtering is 4.5mTorr, the rotation speed of the substrate is 20r / min, the purity of Fe and Ag targets is 99.95%, and the FeAg nano film is obtained;

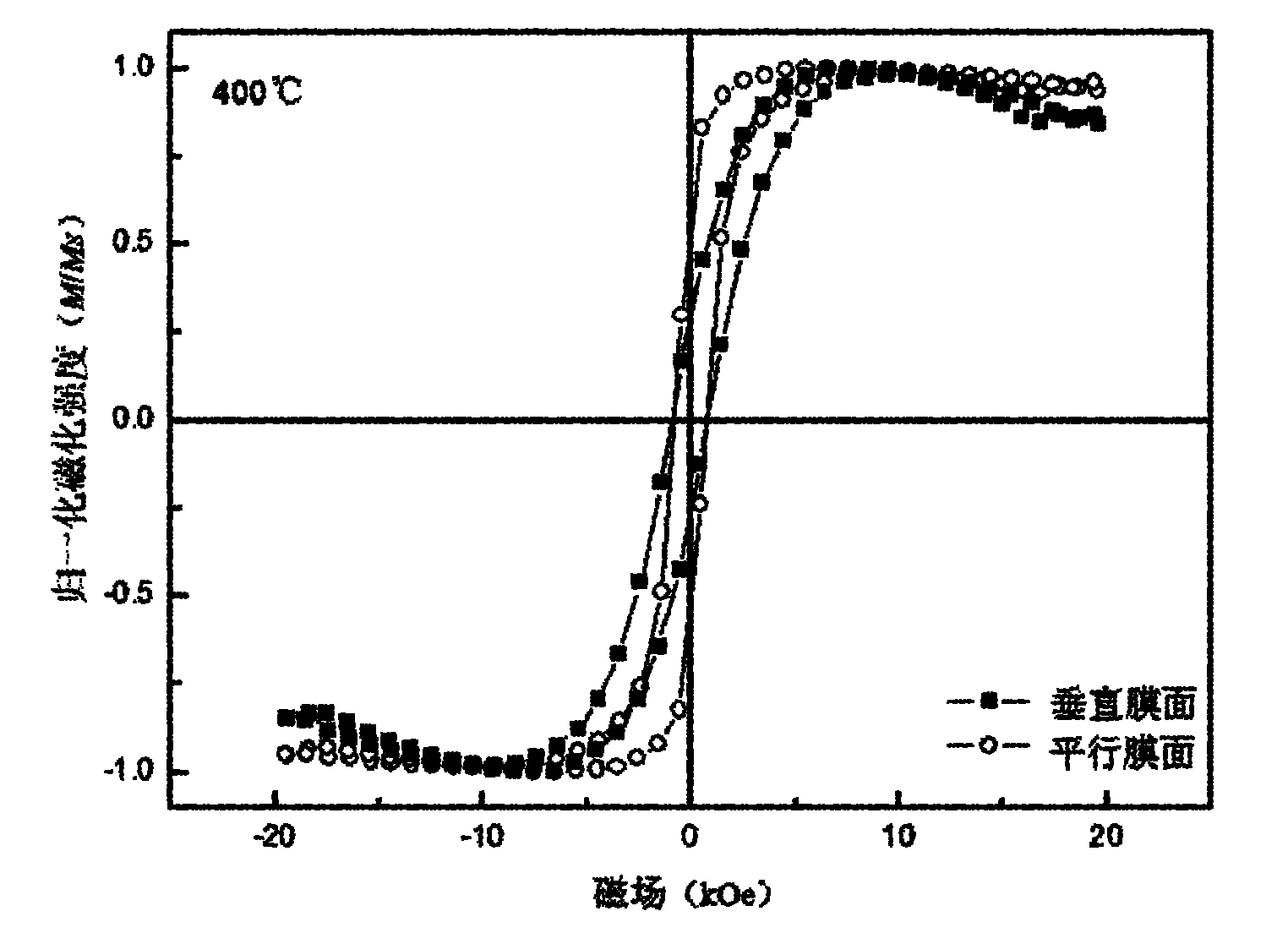

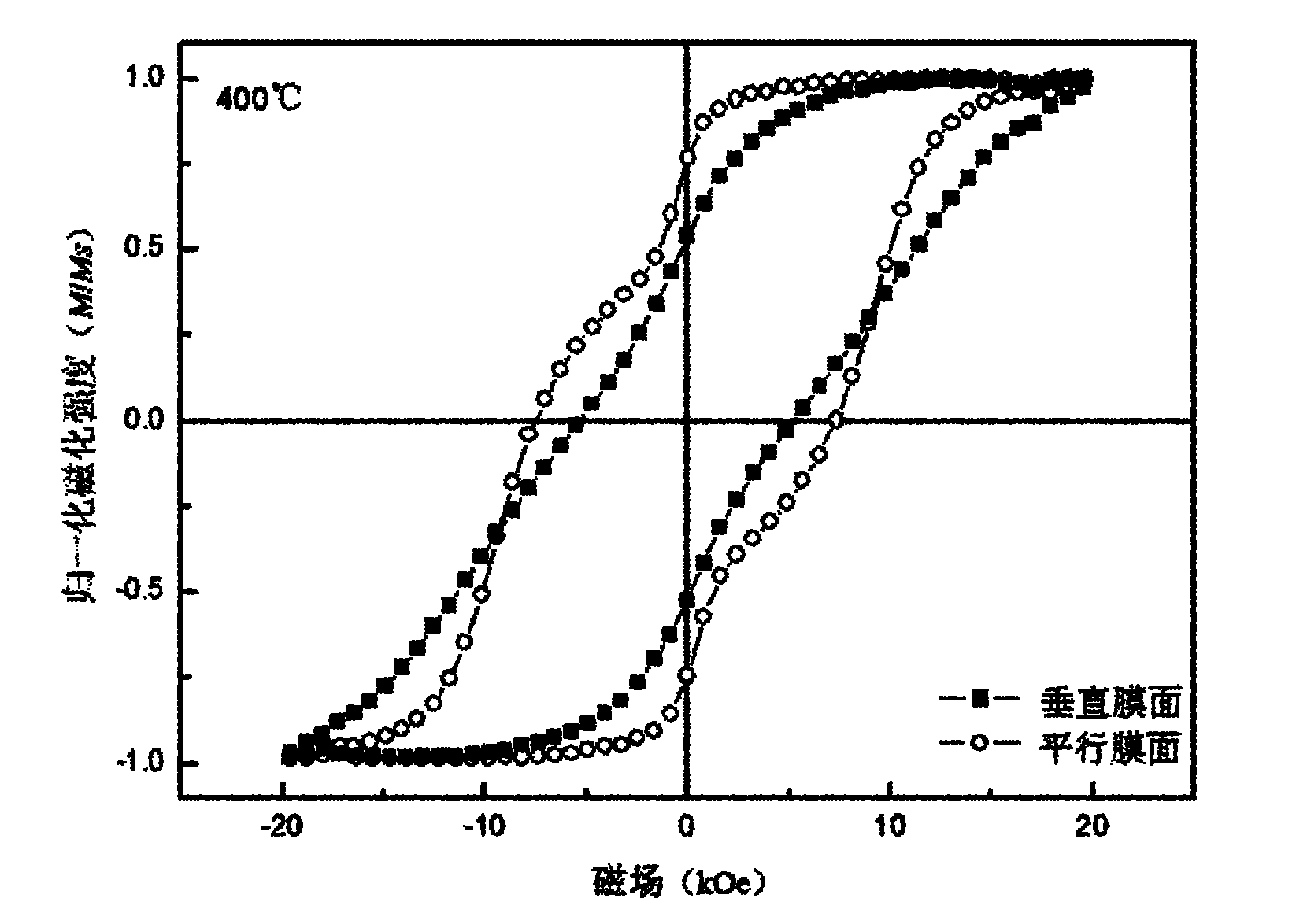

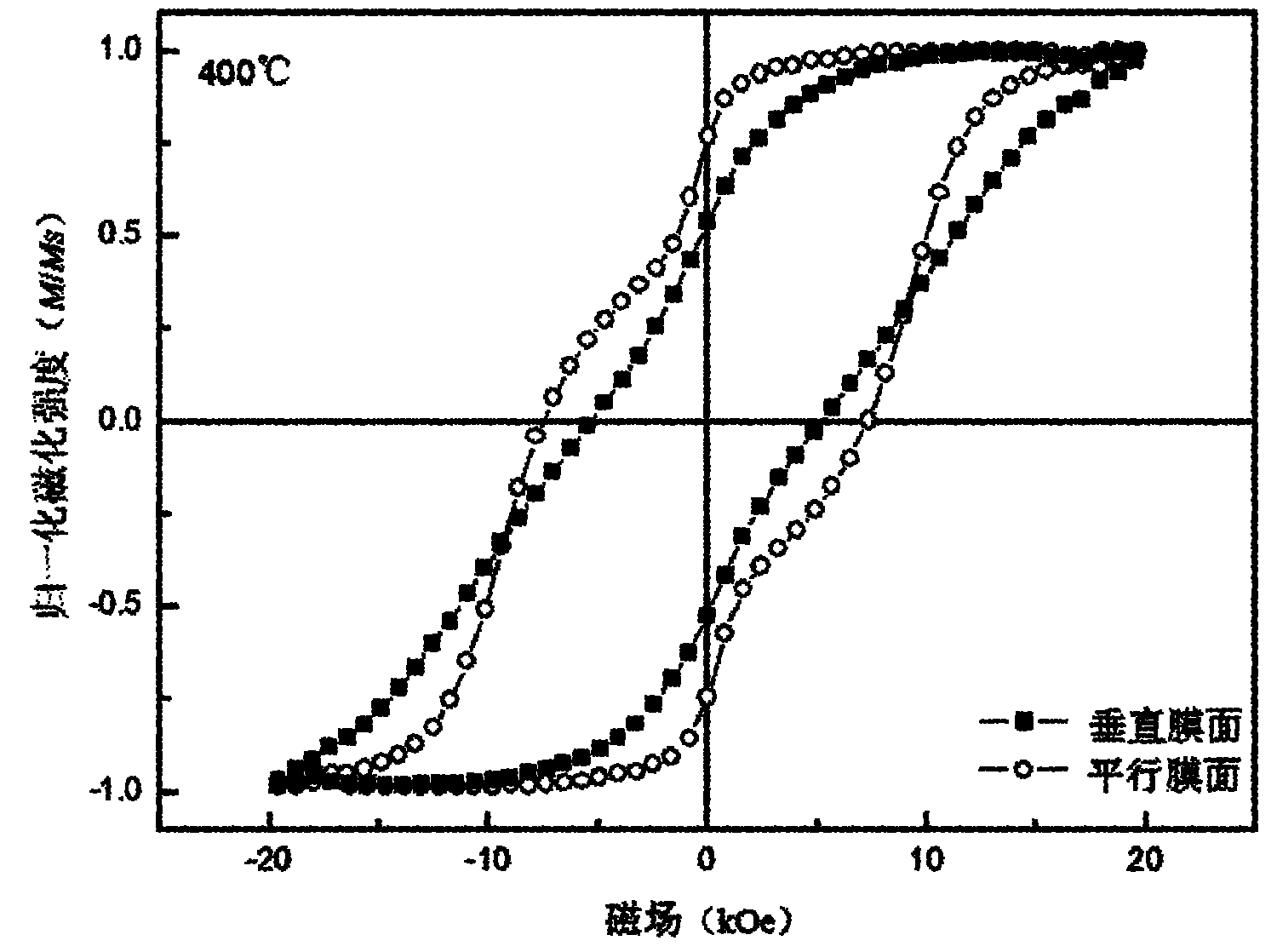

[0027] 3. Annealing treatment: The obtained FeAg thin film samples were annealed at 400°C in a vacuum magnetic annealing furnace under 0 and 10kOe magnetic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com