Method for improving L10-Fept thin film performance with surface activating agent

A surfactant, l10-fept technology, applied in the direction of coating with magnetic layer, cathode sputtering application, sputtering coating, etc., to improve the degree of ordering, fast surface diffusion ability, reduce ordering effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

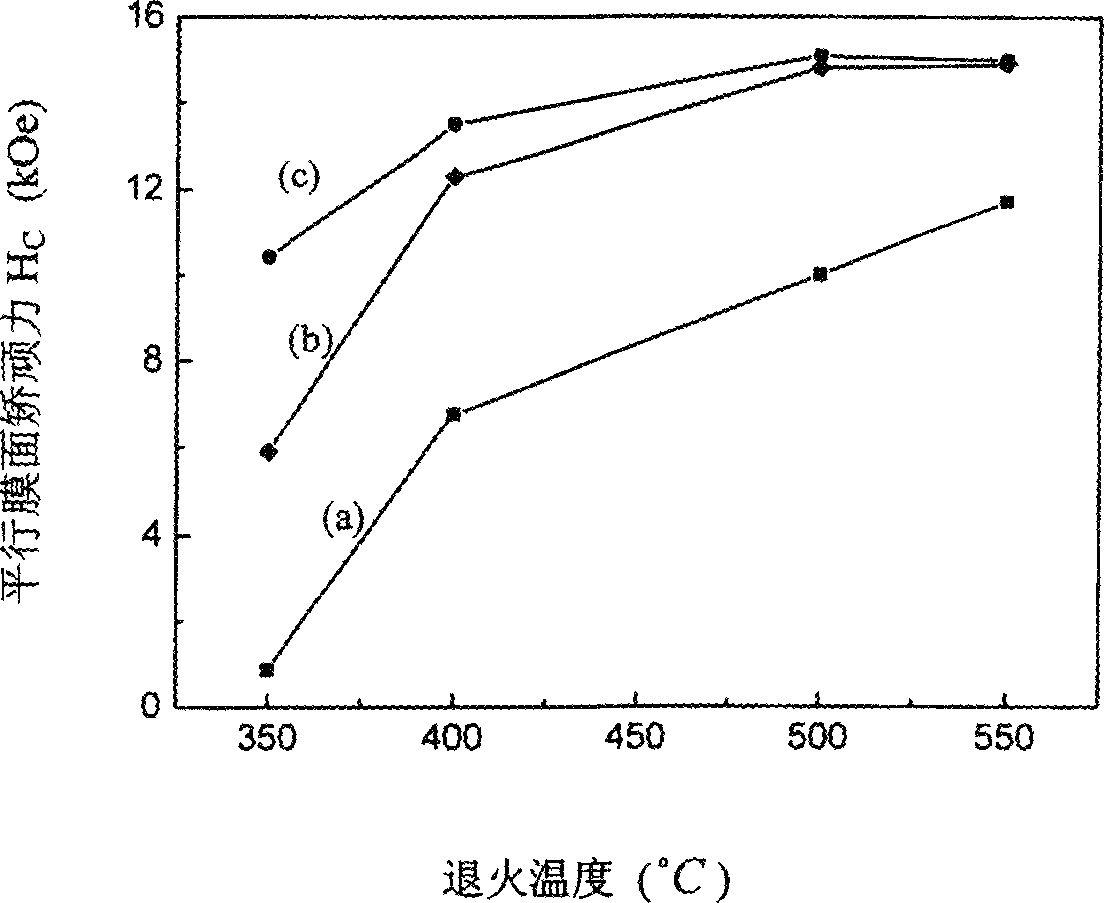

[0011] Thin films were prepared in a magnetron sputtering apparatus. Firstly, the glass substrate is ultrasonically cleaned with organic chemical solvent, deionized water and alcohol, and then placed on the sample base of the sputtering chamber. The substrate was kept at room temperature. Sputtering chamber background vacuum 3×10 -5 Pa, Bi (200 Å) / FePt (200 Å) films were prepared by sequentially depositing bismuth Bi (200 Å) and iron platinum FePt (200 Å) under the condition of sputtering argon gas (purity 99.99%) at a pressure of 0.45 Pa , deposit bismuth Bi (400 Å) and iron platinum FePt (300 Å) to prepare Bi (400 Å) / FePt (300 Å) film. After sputtering, the sample is rapidly vacuumed at a degree of 2×10 -5 Pa heat treatment in vacuum annealing furnace. from figure 1 It can be seen that the FePt film without Bi layer has a higher coercive force (6.8kOe) after annealing at 400°C, while Bi(200) / FePt(200) and Bi(400) / FePt( 300 Å) thin film, the coercivity values reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com