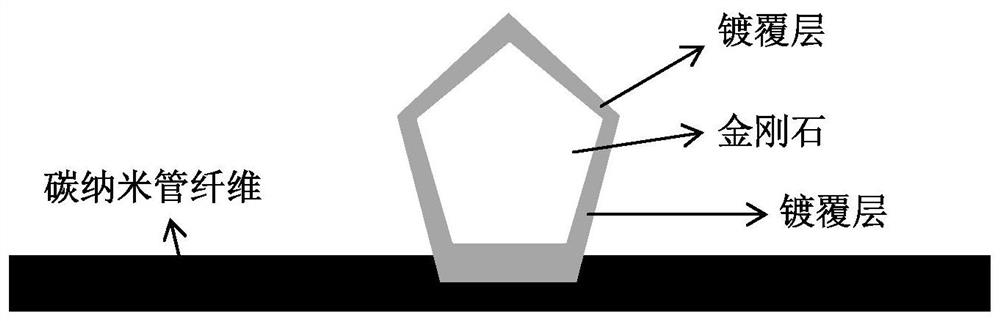

Preparation method of fine-grained diamond-plated carbon nanotube fiber composite material

A carbon nanotube fiber and composite material technology, applied in electrophoretic plating, fiber chemical characteristics, metal processing equipment, etc., can solve the problems of poor diamond dispersion of fiber filaments, poor toughness of ordinary fibers, and poor metal bonding ability, etc., to achieve Enhanced mechanical and electrochemical properties, low degree of graphitization, and enhanced tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

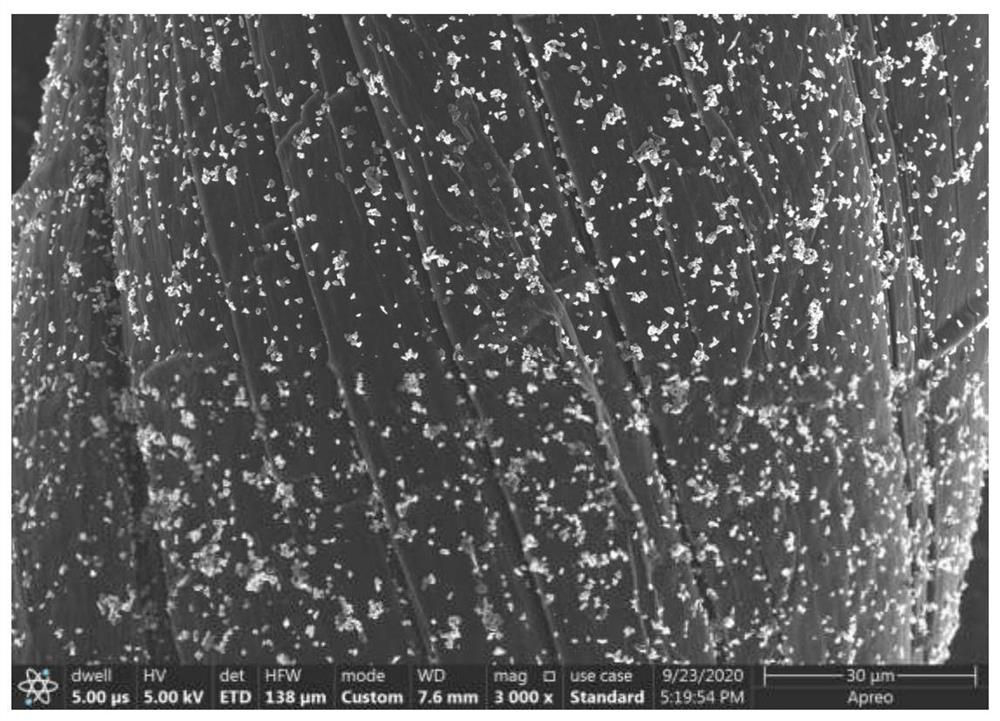

[0037] (1) Evenly mix 32g of diamond with a particle size of 1μm and 8g of titanium powder into a stainless steel container, place the stainless steel container in a vacuum reaction furnace chamber, turn on the vacuum pump and heating valve, and heat up at a rate of 5°C / min to 700°C with a vacuum of 10 -4 Pa, keep warm for 30min, then close the heating valve and cool to 150°C, turn off the vacuum pump, take out the stainless steel container after cooling to room temperature, and obtain coated diamond;

[0038] (2) After the coated diamond obtained in step (1) is cleaned with distilled water, then centrifugally dried, then ultrasonically dispersed in 100 mL of distilled water for 10 min, to make a diamond dispersion with a concentration of 0.005 wt %;

[0039] (3) be 110 μ m and the carbon nanotube fiber that length is 5cm with diameter as positive pole, 304 stainless steel is negative pole, by electrophoretic co-deposition, DC voltage is 5V, and the time is 30s, the diamond di...

Embodiment 2

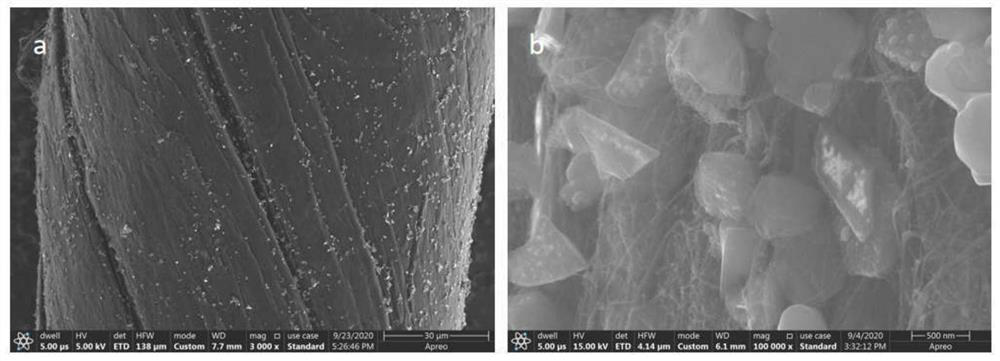

[0042] (1) Evenly mix 40g of diamond with a particle size of 3μm and 8g of molybdenum powder into a stainless steel container, place the stainless steel container in a vacuum reaction furnace chamber, turn on the vacuum pump and heating valve, and heat up at a rate of 5°C / min to 800°C with a vacuum of 10 -3 Pa, keep warm for 30 minutes, then close the heating valve and cool to 150°C, turn off the vacuum pump, take out the stainless steel container after cooling to room temperature, and obtain coated diamond;

[0043] (2) Clean the coated diamond obtained in step (1) with absolute ethanol, then centrifuge and dry it, and then ultrasonically disperse it in 100 mL of absolute ethanol for 10 min to make a diamond dispersion with a concentration of 0.005 wt %;

[0044] (3) be 120 μ m and the carbon nanotube fiber that length is 4cm with diameter as positive pole, 304 stainless steel is negative pole, by electrophoretic co-deposition, DC voltage is 10V, and the time is 20s, the diamon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com