Method for synthesizing ordered array of single crystal Sic Nano filament with small diameter through heat evaporation method

A thermal evaporation method and ordered array technology, which is applied in the field of nanomaterials, can solve the problems of complex process of SiC nanowire ordered array and cannot be synthesized by direct reaction, and achieves low gas price, low cost, and simple and easy process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The synthesis process is carried out in a simple horizontal quartz tube furnace. A ceramic boat containing 2g of ZnS powder and 3 clean silicon wafers is placed in the center of the tube furnace, and the carbon material is fixed in the quartz tube through sintering. side of entry. First, the temperature was raised to 900°C at a rate of 25°C / min, and then to a reaction temperature of 1100°C at a rate of 15°C / min. When the temperature reaches 250°C, argon gas with a gas flow rate of 5 l / h is introduced; at a reaction temperature of 1100°C, the gas flow rate in the chamber is maintained, and the reaction continues for 2 hours. After the reaction, the reaction product is taken out and placed on a silicon wafer A large number of ordered arrays of small-diameter single-crystal SiC nanowires were obtained on the surface.

Embodiment 2

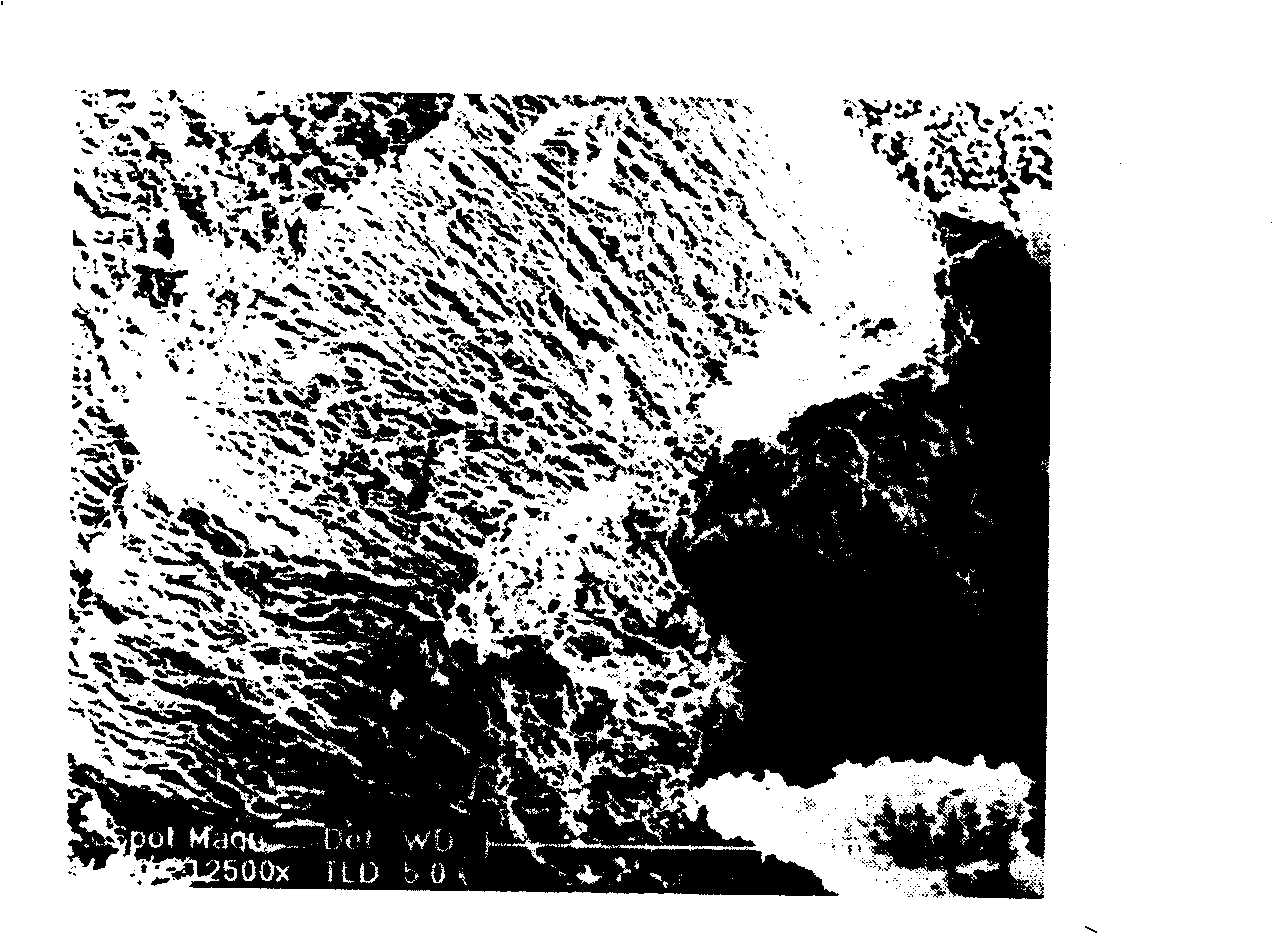

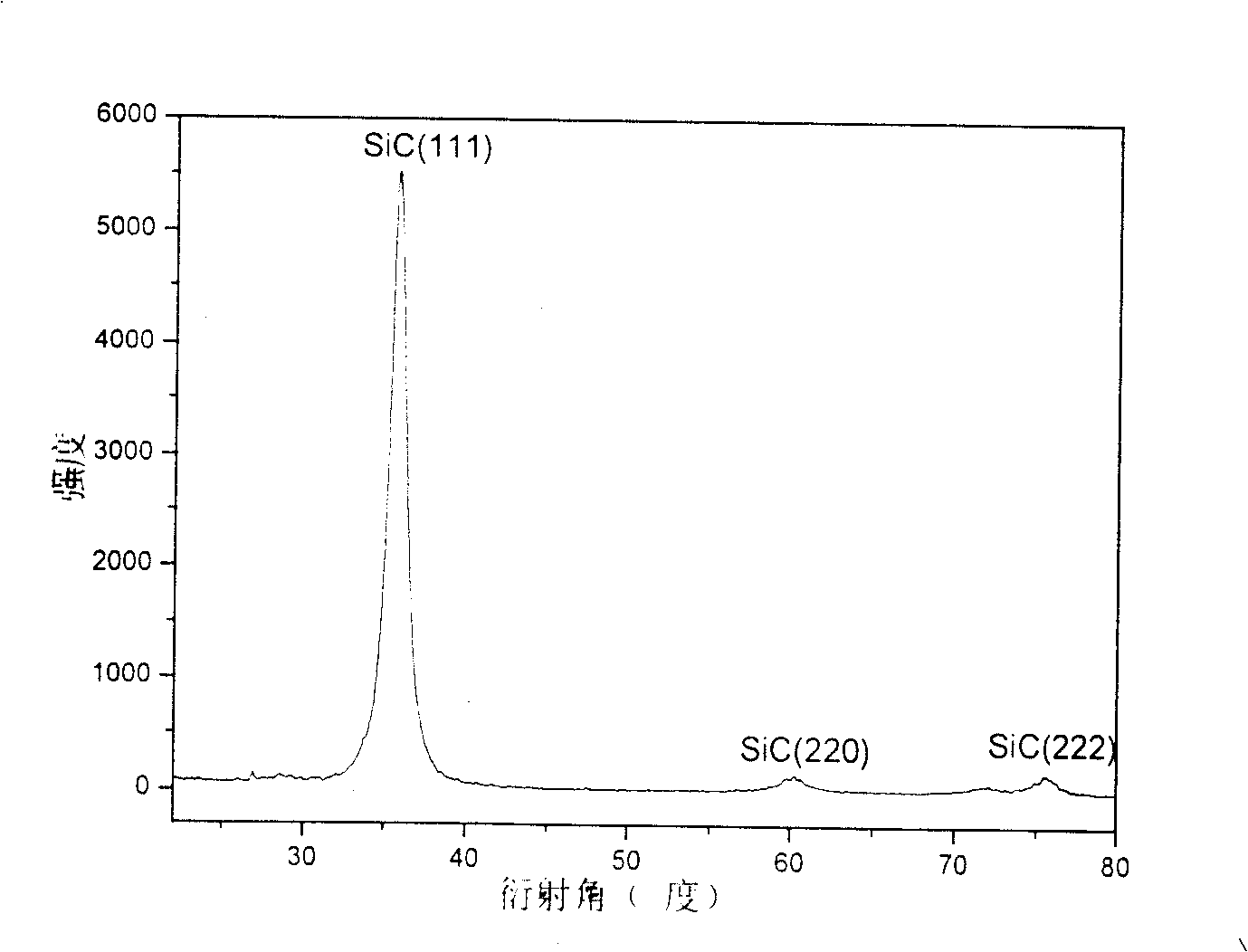

[0030] The synthesis process is carried out in a simple horizontal quartz tube furnace. A ceramic boat containing 3g of ZnS powder and 5 clean silicon wafers is placed in the center of the tube furnace, and the carbon material is fixed in the quartz tube through sintering. side of entry. First, the temperature was raised to 900°C at a rate of 25°C / min, and then to a reaction temperature of 1100°C at a rate of 15°C / min. When the temperature reaches 250°C, the inert gas argon gas with a gas flow rate of 16 l / h is introduced; at a reaction temperature of 1100°C, the gas flow rate in the chamber is maintained, and the reaction continues for 3 hours. After the reaction is completed, the reaction product is taken out. A large number of small-diameter single-crystal SiC nanowire ordered arrays were obtained on the surface of the silicon wafer (see figure 1 ). It can be seen from the figure that a large number of SiC nanowire arrays arranged in an orderly manner are produced on the ...

Embodiment 3

[0032] The synthesis process is carried out in a simple horizontal quartz tube furnace. A ceramic boat containing 4g of ZnS powder and 4 clean silicon wafers is placed in the center of the tube furnace, and the carbon material is fixed in the quartz tube through sintering. side of entry. First, the temperature was raised to 900°C at a rate of 25°C / min, and then to a reaction temperature of 1100°C at a rate of 15°C / min. When the temperature reaches 250°C, the inert gas argon gas with a gas flow rate of 30 l / h is introduced; at a reaction temperature of 1100°C, the gas flow rate in the chamber is maintained, and the reaction continues for 4 hours. After the reaction is completed, the reaction product is taken out. A large number of ordered arrays of small-diameter single-crystal SiC nanowires were obtained on the surface of the silicon wafer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com