Magnetic recording medium based on FePt magnetic layer and producing method thereof

A technology of magnetic recording medium and magnetic layer, which is applied in the field of information storage and can solve the problems of increasing annealing temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

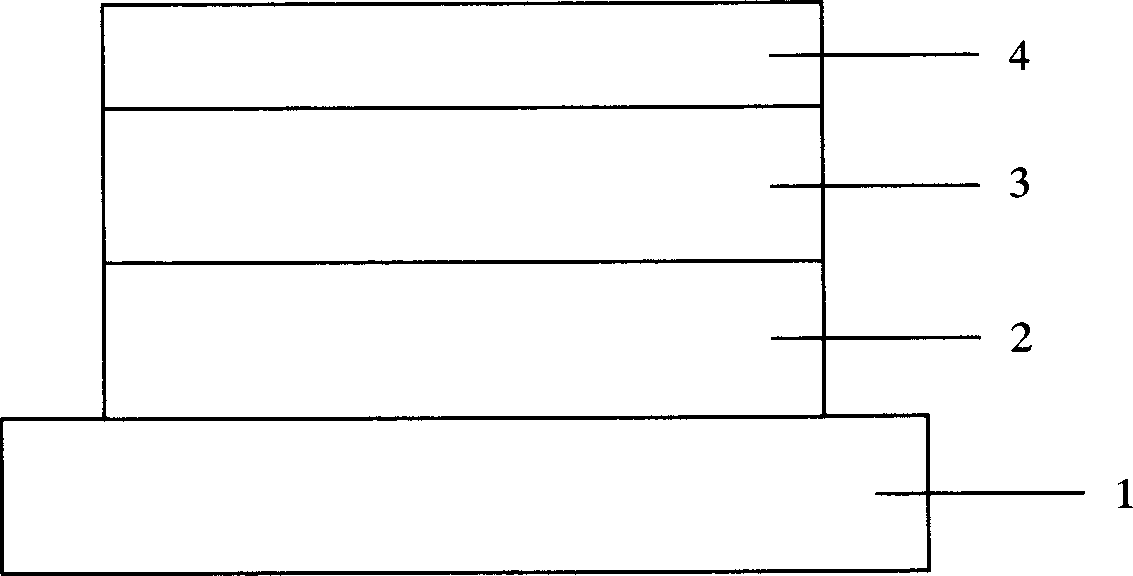

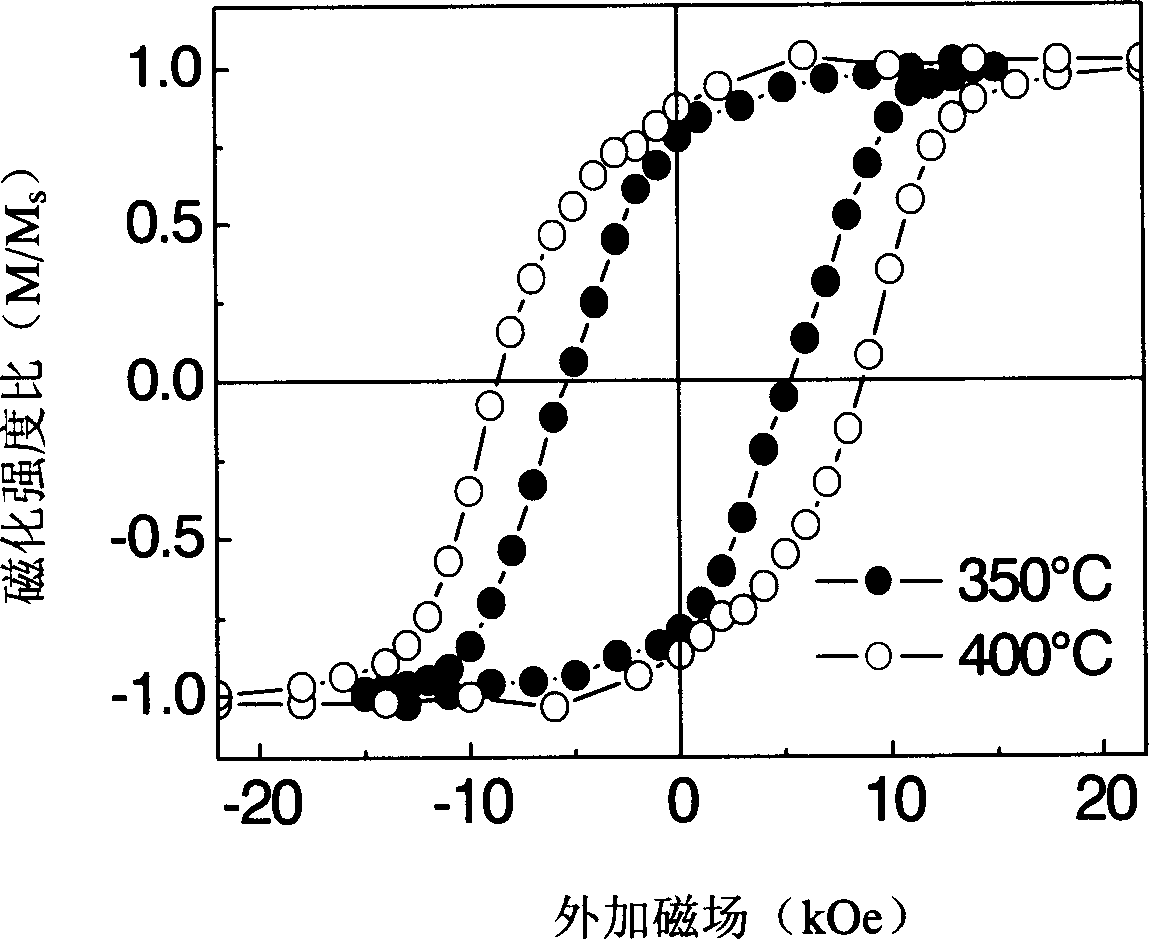

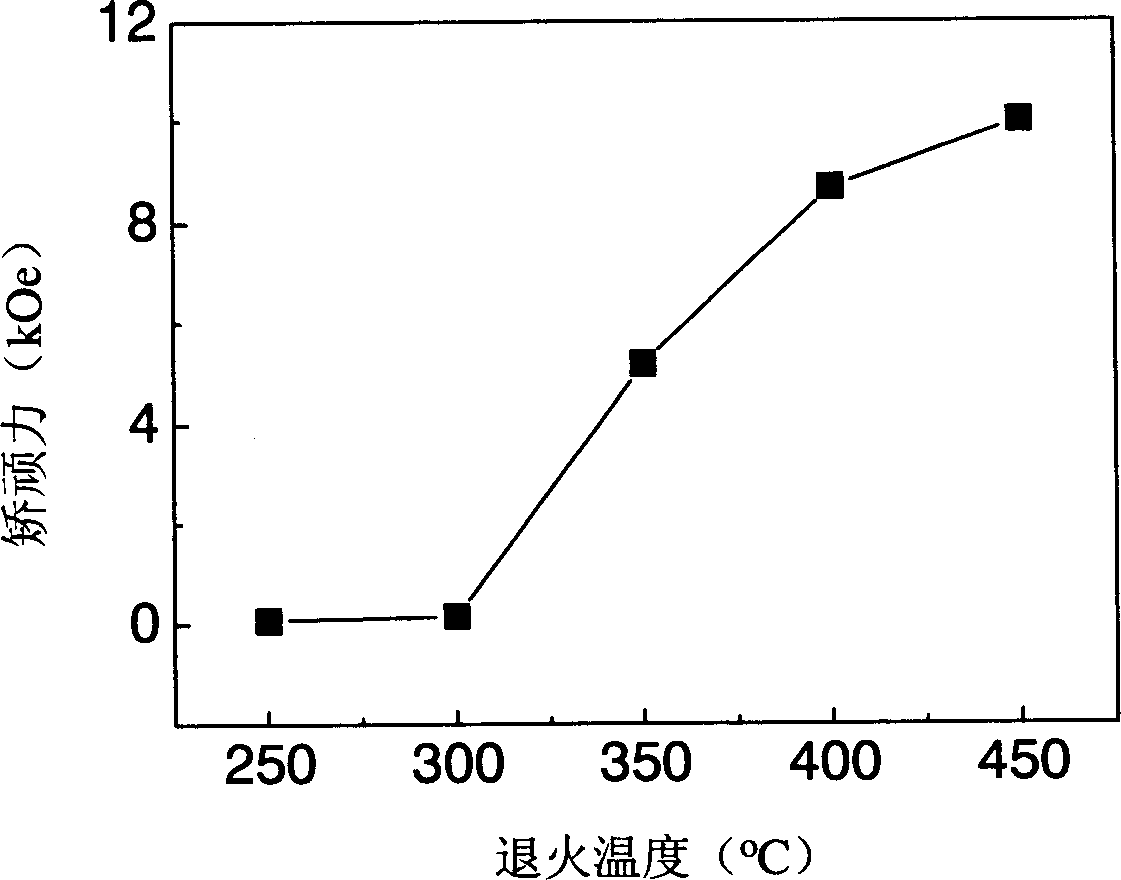

[0022] The structure of the magnetic recording medium based on the FePt magnetic layer is: substrate glass 1, the AuCu buffer layer 2 with a thickness of 10nm, the FePt magnetic layer 3 with a thickness of 9nm, and the protective layer 4 (material is C) with a thickness of 5nm, all The thickness or composition of each layer is the value when the sample was vacuum deposited or before annealing. figure 2 It is the hysteresis loop measured by a vibrating sample magnetometer and a superconducting quantum magnetometer after the product has undergone vacuum annealing at temperatures of 350°C and 400°C for 1 hour. image 3 The dependence of the coercivity of this product on the annealing temperature is shown.

Embodiment 2

[0024] The structure of the magnetic recording medium based on the FePt magnetic layer is: a substrate glass 1, an AuCu buffer layer 2 with a thickness of 1nm to 50nm, a FePt magnetic layer 3 with a thickness of 9nm, and a protective layer 4 with a thickness of 5nm (the material is C) , all thicknesses or compositions of the individual layers are the values when the samples were vacuum deposited or before annealing. Figure 4 It shows the dependence of the coercivity of the product on the thickness of the buffer layer after vacuum annealing at 350°C and 400°C for 1 hour.

Embodiment 3

[0026] The structure of the magnetic recording medium based on the FePt magnetic layer is: a substrate glass 1, an AuCu buffer layer 2 with a thickness of 10nm, a FePt magnetic layer 3 with a thickness of 2nm to 50nm, and a 5nm protective layer 4 (material is C), All thicknesses or compositions of individual layers are at the time of vacuum deposition of the samples or before annealing. Figure 5 The dependence of the coercivity of the product on the thickness of the magnetic layer after vacuum annealing at 350°C and 400°C for 1 hour is shown.

[0027] The preparation method of the magnetic recording medium based on FePt magnetic layer of the present invention is described below with embodiment 1:

[0028] First adopt vacuum deposition method, such as magnetron sputtering method, the background vacuum degree is better than 10 -5 Pa, and the deposition working pressure under inert atmosphere is 5×10 -1 Pa to 6×10 -1 Pa, a buffer layer AuCu, a magnetic layer FePt, and a prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com