Micro-structured optical fiber for generating and transmitting vortex light beams

A technology of micro-structured optical fiber and vortex beam, applied in the direction of multi-layer core/clad optical fiber, clad optical fiber, etc., can solve problems such as difficult matching, and achieve the effects of reducing manufacturing cost, reducing process difficulty, and periodic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principle on which the technical solution provided by the invention is:

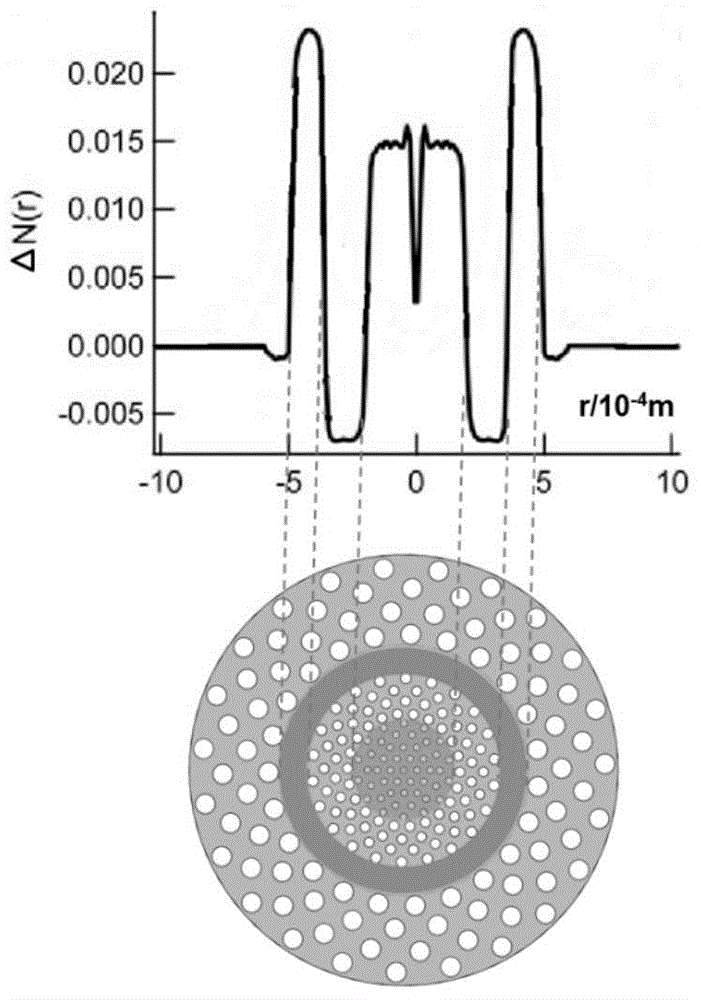

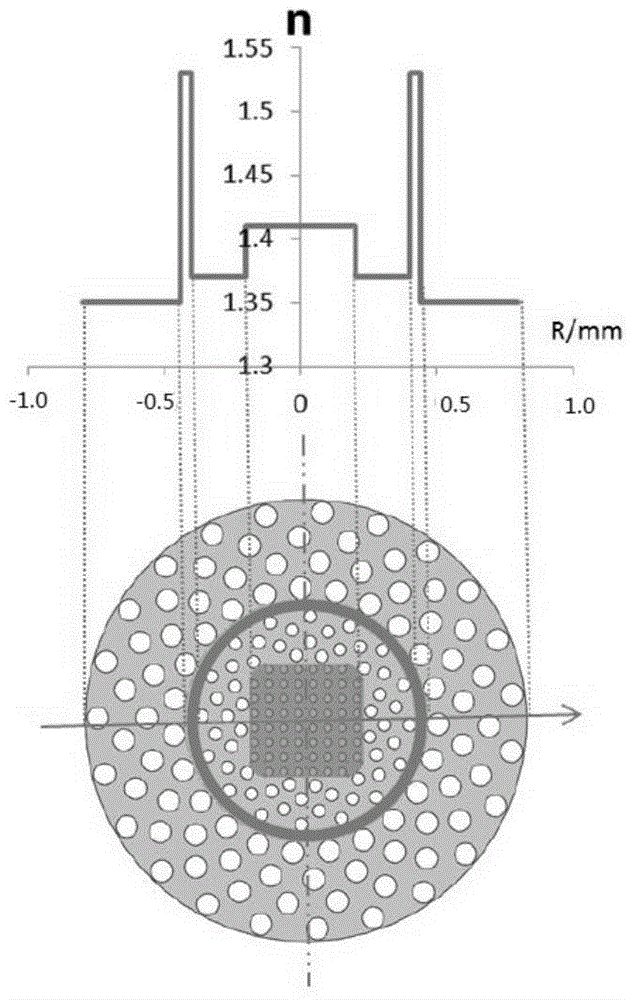

[0020] By adopting COP as the structural material of the vortex fiber, the design requirements of high-purity separation of different vortex beams are achieved with the subwavelength porous fiber structure; the design of the subwavelength porous core reduces material loss, and the macroporous cladding structure , to achieve the design requirements of adjusting the refractive index and reducing the loss, increasing the flexibility of the optical fiber. On this basis, high-quality (no impurities, no bubbles), large-size (7 cm diameter, 50 cm length) vortex optical fiber preform with square core and ring core, and vortex optical fiber prefabricated with round core and ring core are prepared. Rods; master the optimal process conditions for thermoforming preforms with two different structures; prepare two high-quality preforms with the best technology; use the preforms to pull out vortex optical fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com