Core-shell silicon carbon composite negative electrode material for high-capacity type lithium ion battery and preparation method therefor

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of difficult formation of solid electrolyte interface, aggravation of silicon corrosion and capacity decay, and active material shedding and other problems, to achieve excellent cycle stability, improve cycle stability, and improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

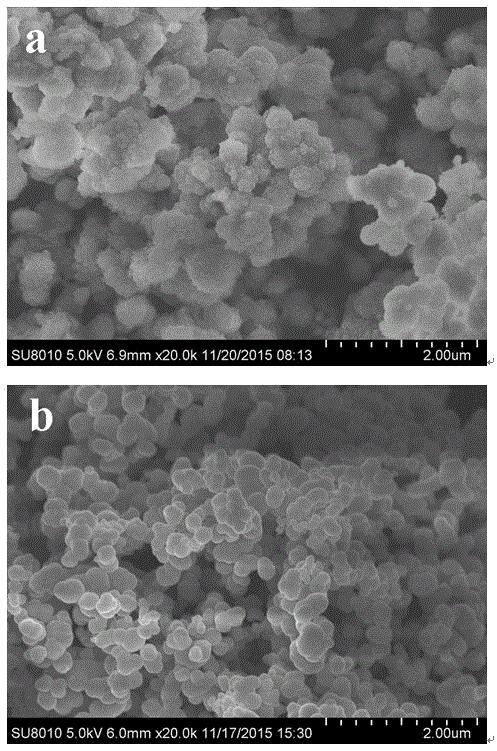

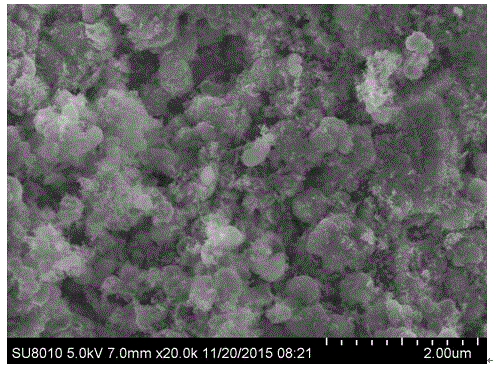

Embodiment 1

[0025] A method for preparing a silicon-carbon negative electrode material for a high-capacity lithium-ion battery, comprising the following steps:

[0026] (1) Add 0.5g of silicon nanoparticles and 0.05g of polyvinylpyrrolidone into 100mL of deionized water, ultrasonically disperse for 30min until the particles are evenly dispersed, and set aside.

[0027] (2) Take 40mL of the above solution and add 0.2g of glucose. After dissolving, transfer the solution to a reaction kettle with a polytetrafluoroethylene lining and seal it. Keep it warm at 180°C for 12h in a muffle furnace, and cool down to room temperature naturally. The solid product was centrifuged, washed, and vacuum-dried to obtain a silicon / amorphous carbon composite.

[0028] (3) The solid product obtained in step (2) was placed in a tube furnace under an Ar inert atmosphere, and was heated to 1000°C for carbonization for 1 hour to obtain the silicon-carbon composite negative electrode material of Example 1.

Embodiment 2

[0030] (1) Add 0.2g of silicon nanoparticles and 0.1g of polyvinylpyrrolidone into 40mL of deionized water, ultrasonically disperse for 5min until the particles are evenly dispersed, and set aside.

[0031] (2) Add 0.4g of citric acid to the above solution. After dissolving, transfer the solution to a reaction kettle with a polytetrafluoroethylene lining and seal it. Keep it in a muffle furnace at 220°C for 8 hours, and cool it down to room temperature naturally. The solid product was centrifuged, washed, and vacuum-dried to obtain a silicon / amorphous carbon composite.

[0032] (3) Place the solid product obtained in step (2) in a tube furnace, N 2 Under an inert atmosphere, the temperature was raised to 800° C. for carbonization for 5 hours to obtain the silicon-carbon composite negative electrode material of Example 2.

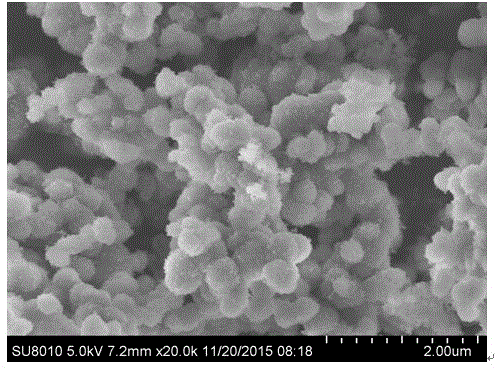

Embodiment 3

[0034] (1) Add 0.5g of silicon nanoparticles and 0.025g of cetyltrimethylammonium bromide into 50mL of deionized water, ultrasonically disperse for 60min until the particles are evenly dispersed, and set aside.

[0035] (2) Add 0.15g of starch and 0.1g of sucrose to the above solution. After dissolving, transfer the solution to a reaction kettle with a polytetrafluoroethylene lining and seal it. Keep it in a muffle furnace at 150°C for 24h, and cool it down to room temperature naturally. . The solid product was centrifuged, washed and dried in vacuo.

[0036] (3) The solid product obtained in step (2) was placed in a tube furnace, and under an Ar inert atmosphere, the temperature was raised to 900°C for carbonization for 2 hours, and the silicon-carbon composite negative electrode material of Example 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com