Preparation method for porous graphitized hard carbon for high-rate sodium ion battery cathode

A sodium-ion battery, porous graphite technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of poor rate performance, poor conductivity, capacity decline, etc., and achieve improved conductivity, easy operation, and steps. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

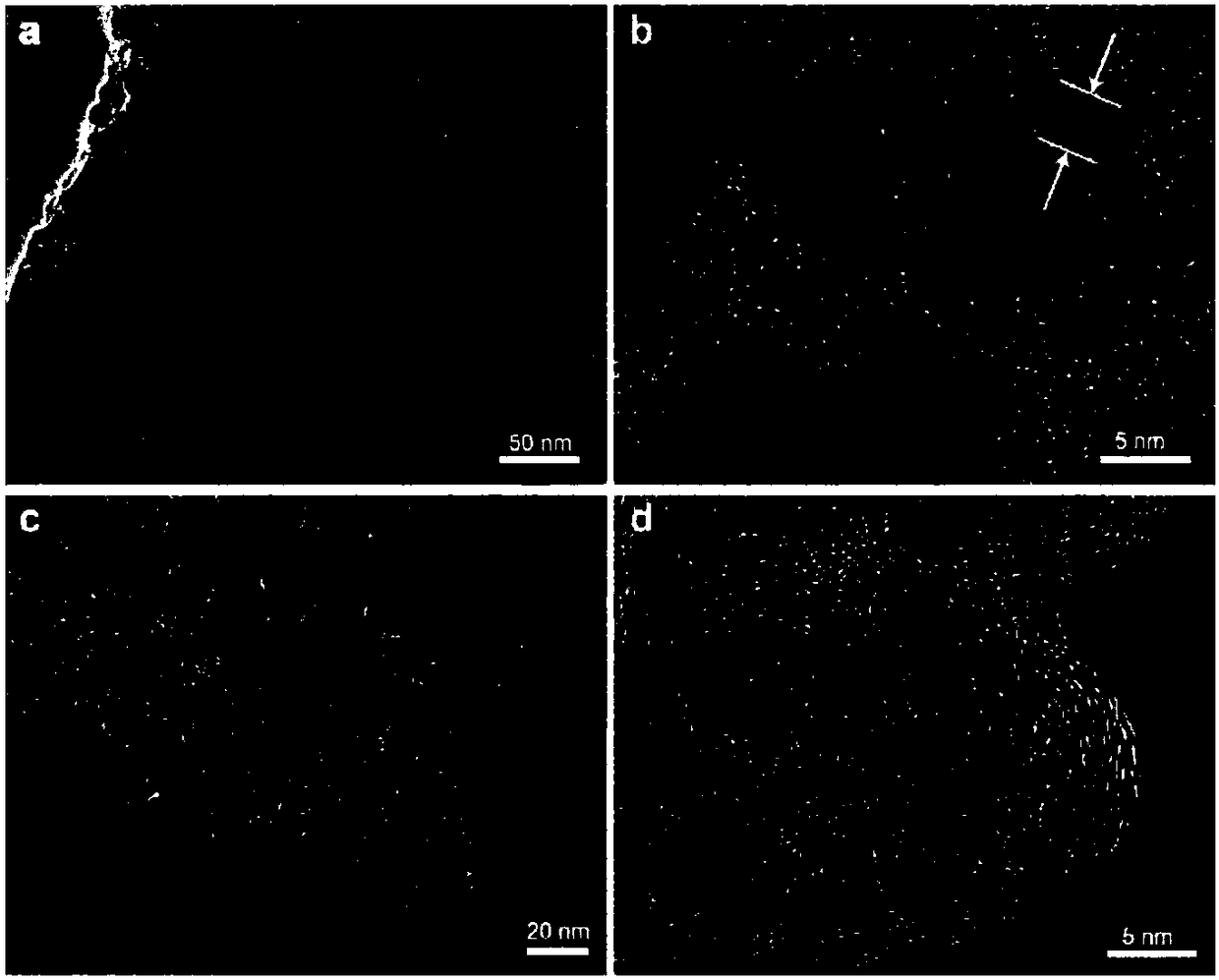

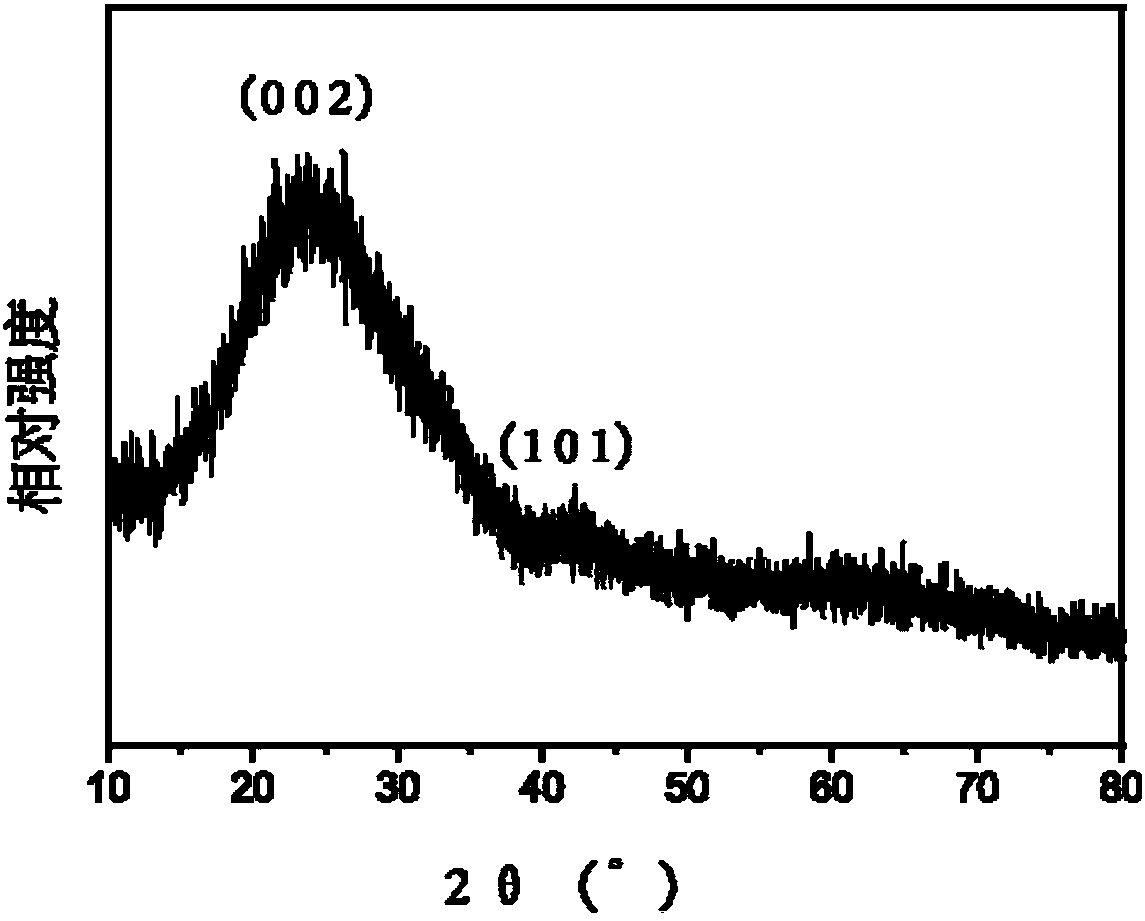

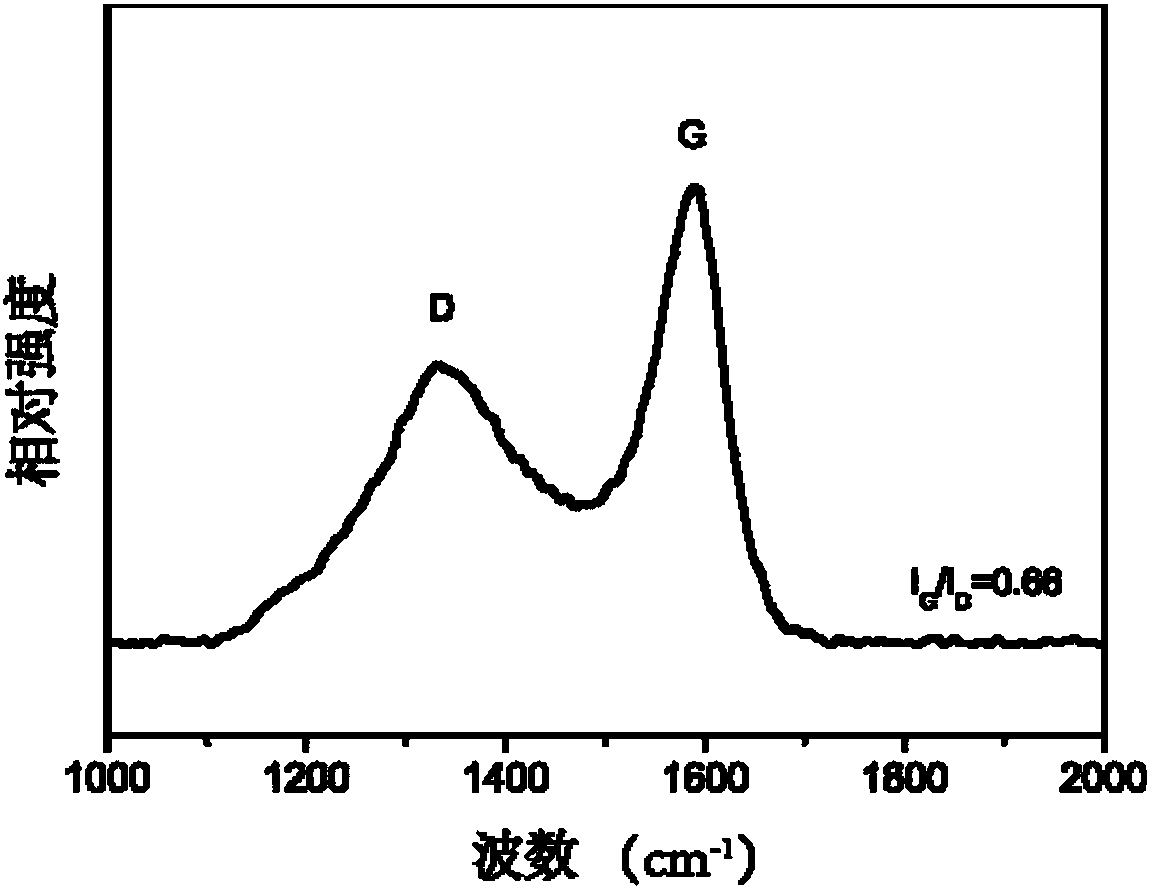

[0034] This embodiment relates to a preparation method of porous graphitized hard carbon for a negative electrode of a high-rate sodium ion battery, comprising the following steps:

[0035] (1) Cross-linking reaction: 25 g of sodium alginate was dissolved in 975 mL of deionized water to prepare a solution with a mass fraction of 2.5%. Dissolve 50 g of cobalt nitrate in 950 mL of deionized water to prepare a solution with a mass fraction of 5%. The sodium alginate solution was slowly added dropwise into the cobalt nitrate solution, and the volume ratio of the sodium alginate solution to the cobalt nitrate solution was 4:5. Let stand for 24 hours and wait for the cross-linking reaction to complete. Soak the cobalt alginate obtained by cross-linking in deionized water, wash it repeatedly three times, remove the cobalt ions on the surface that do not participate in the cross-linking reaction, and then freeze-dry for 24 hours.

[0036] (2) Carbonization: Transfer the freeze-dried...

Embodiment 2

[0041] This embodiment relates to a preparation method of porous graphitized hard carbon for a negative electrode of a high-rate sodium ion battery, comprising the following steps:

[0042] (1) Take 2 g of sodium alginate and dissolve it in 998 mL of deionized water to prepare a solution with a mass fraction of 0.2%. Take 25g of nickel nitrate and dissolve it in 975mL of deionized water to prepare a solution with a mass fraction of 2.5%. The sodium alginate solution is placed in a spray bottle and slowly sprayed into the nickel nitrate solution to obtain a nickel alginate gel film. The nickel alginate gel film was washed three times with deionized water, and freeze-dried for 24 hours.

[0043] (2) Take dry nickel alginate, put it into a tube furnace, pass in argon gas, raise the temperature to 1200°C at a rate of 10°C / min, keep it warm for 12 hours, take it out after natural cooling, and obtain nano-nickel / carbon composite Material.

[0044] (3) Add the nano-nickel / carbon c...

Embodiment 3

[0047] This embodiment relates to a preparation method of porous graphitized hard carbon for a negative electrode of a high-rate sodium ion battery, comprising the following steps:

[0048] (1) Take 100g of sodium alginate and dissolve it in 900mL of deionized water to prepare a solution with a mass fraction of 10%. Take 100g of ferric nitrate and dissolve it in 900mL of deionized water to prepare a solution with a mass fraction of 10%. The sodium alginate solution and the ferric nitrate solution were mixed according to the mass ratio of 1:1. The obtained iron alginate gel was repeatedly washed three times with deionized water, and freeze-dried for 24 hours.

[0049] (2) Take dry iron alginate, put it into a tube furnace, pass in argon gas, raise the temperature to 1000°C at a rate of 10°C / min, keep it warm for 12 hours, take it out after natural cooling, and obtain nano-iron / carbon composite Material.

[0050] (3) Add the nano-nickel / carbon composite material into 1L hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com