Novel method for synthesizing cubic phase interpose porus molecular sieve material

A technology of mesoporous molecular sieve and cubic phase, which is applied in the field of synthesis of cubic phase mesoporous molecular sieve materials, can solve the problems of incomplete polymerization of mesoporous molecular sieve walls, hinder the stability of mesoporous materials, and poor hydrothermal stability, etc., and achieve improvement Hydrogenation reaction activity, high degree of order, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

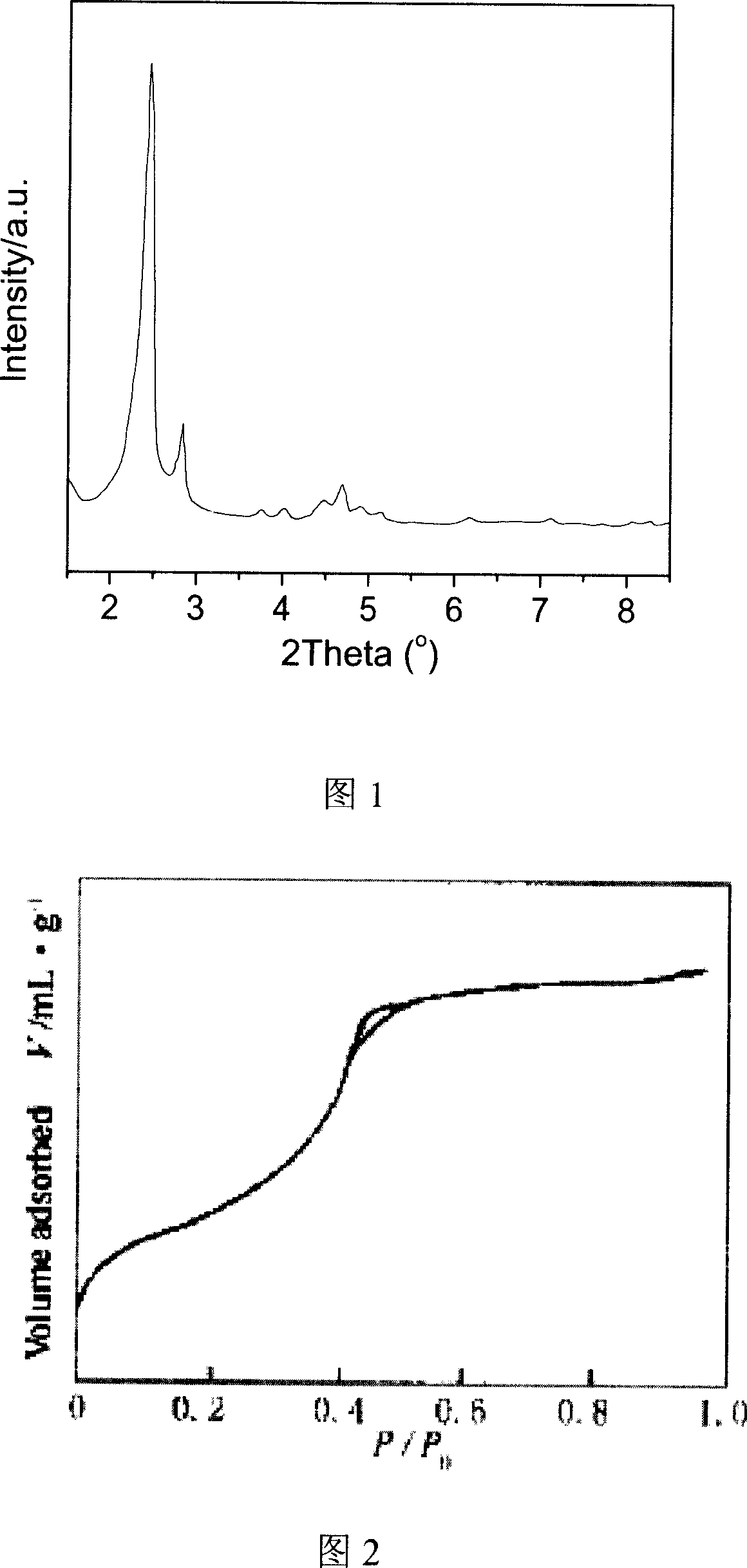

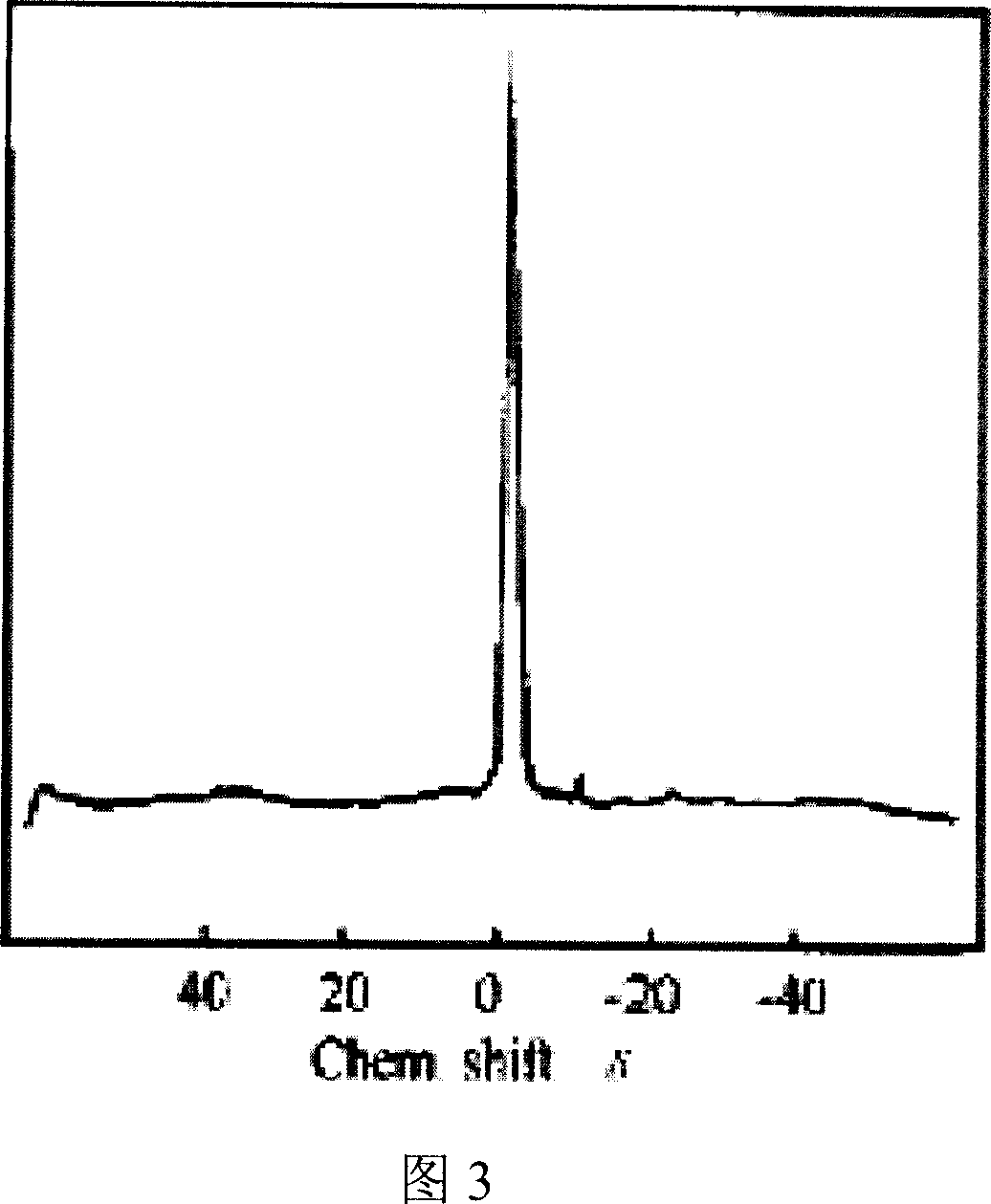

[0023] 0.001mol C 16 TMABr and 0.001mol C 18-3-1 Br 2 Completely dissolve in 3.25mol water, add 0.0015mol triethanolamine, stir well, add 0.2ml NaOH solution (1mol / l, containing 0.008mol NaOH), mix well, then add 0.001mol boric acid, continue stirring until boric acid is completely dissolved , while stirring, add 5.3ml of silica sol (SiO 2 6mol / l, containing 0.032mol SiO 2 ), stirred for 2 to 4 hours, then adjusted the pH value to 9 to 10 with hydrochloric acid, filled into a 100ml stainless steel reactor (with a polytetrafluoroethylene liner inside) after full stirring, and crystallized at 373K for 72 hours, wherein each Every 12 hours, adjust the pH value to be in the above range. After the reaction, the product was separated, washed and dried at room temperature. The dried product was mixed with deionized water at 1:20 (weight ratio), heated at 373K for 10 days, then filtered, dried, and calcined at 823K for 4 hours. It was identified by XRD that it had cubic phase (Ia...

Embodiment 2

[0028] 0.001mol C 16 TMACl and 0.0015mol C 16-3-1 Br 2 Completely dissolve in 3.54mol water, add 0.0014mol dimethylethanolamine, stir well, add 0.2ml 1mol / l NaOH solution (containing 0.008mol NaOH), mix well, add 0.0015mol boric acid, continue stirring until boric acid dissolves, then, in Under the condition of stirring, 6.7ml ethyl orthosilicate (containing 0.03mol SiO 2 ), after stirring for 4 hours, adjust the pH value to 9-10 with hydrochloric acid, fully stir it and put it into a 100ml stainless steel reactor, and crystallize it at 373K for 72 hours, wherein every 12 hours, adjust the pH value to be in the above-mentioned range. After the reaction, the product was separated, washed and dried at room temperature. The dried product was mixed with deionized water at 1:20 (weight ratio), heated at 373K for 10 days, then filtered, dried, and calcined at 823K for 4 hours. It was identified by XRD that it had cubic phase (Ia3d) mesoporous characteristics.

Embodiment 3

[0030] 0.001mol C 14 TMABr and 0.0018mol C 18-3-1 Br 2 Completely dissolve in 3.54mol water, add 0.001mol triethanolamine, stir well, add 0.3ml NaOH solution (1mol / l, containing 0.012mol NaOH), mix well, add 0.001mol boric acid, continue stirring until the boric acid is completely dissolved, then stir Under conditions, add 6.7ml ethyl orthosilicate (containing 0.03mol SiO 2 ), after stirring for 4 hours, adjust the pH value to 9 to 10 with hydrochloric acid, put into a 100ml stainless steel reaction kettle (with a polytetrafluoroethylene liner inside) after fully stirring, and crystallize at 373K for 72 hours, wherein every 12 Hours, adjust the pH value in the above range. After the reaction, the product was separated, washed and dried at room temperature. The dried product was mixed with deionized water at 1:20 (weight ratio), heated at 373K for 10 days, then filtered, dried, and calcined at 823K for 4 hours. It was identified by XRD that it had cubic phase (Ia3d) mesopor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com