A two-dimensional nitrogen-doped porous carbon nanosheet and its preparation method

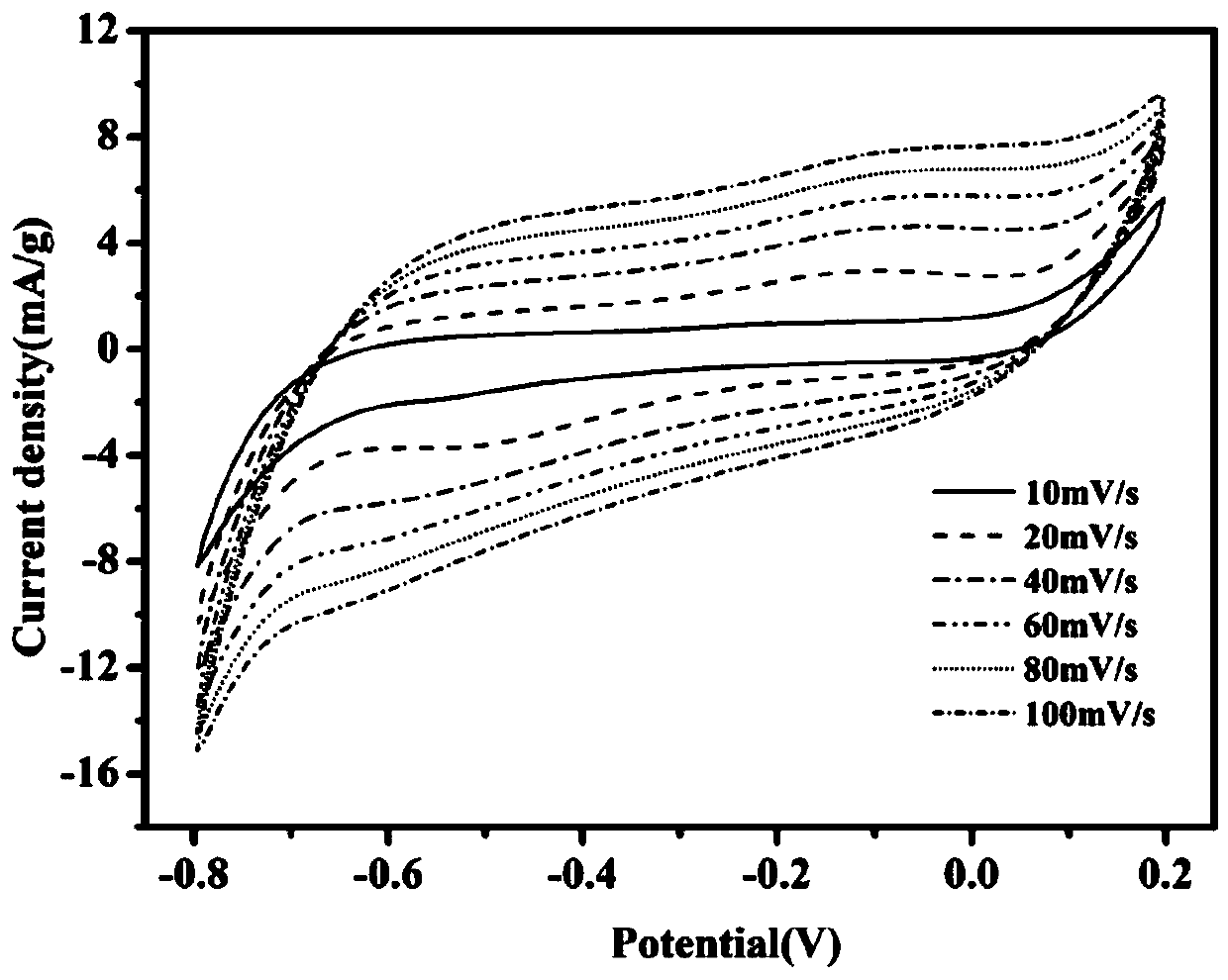

A technology of nitrogen-doped porous carbon and carbon nanosheets, which is applied in the manufacture of nano-carbon, hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of uneven mesopores, easy agglomeration, and poor cycle stability of capacitors. Achieve the effects of promoting uniform dispersion, improving doping quality, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

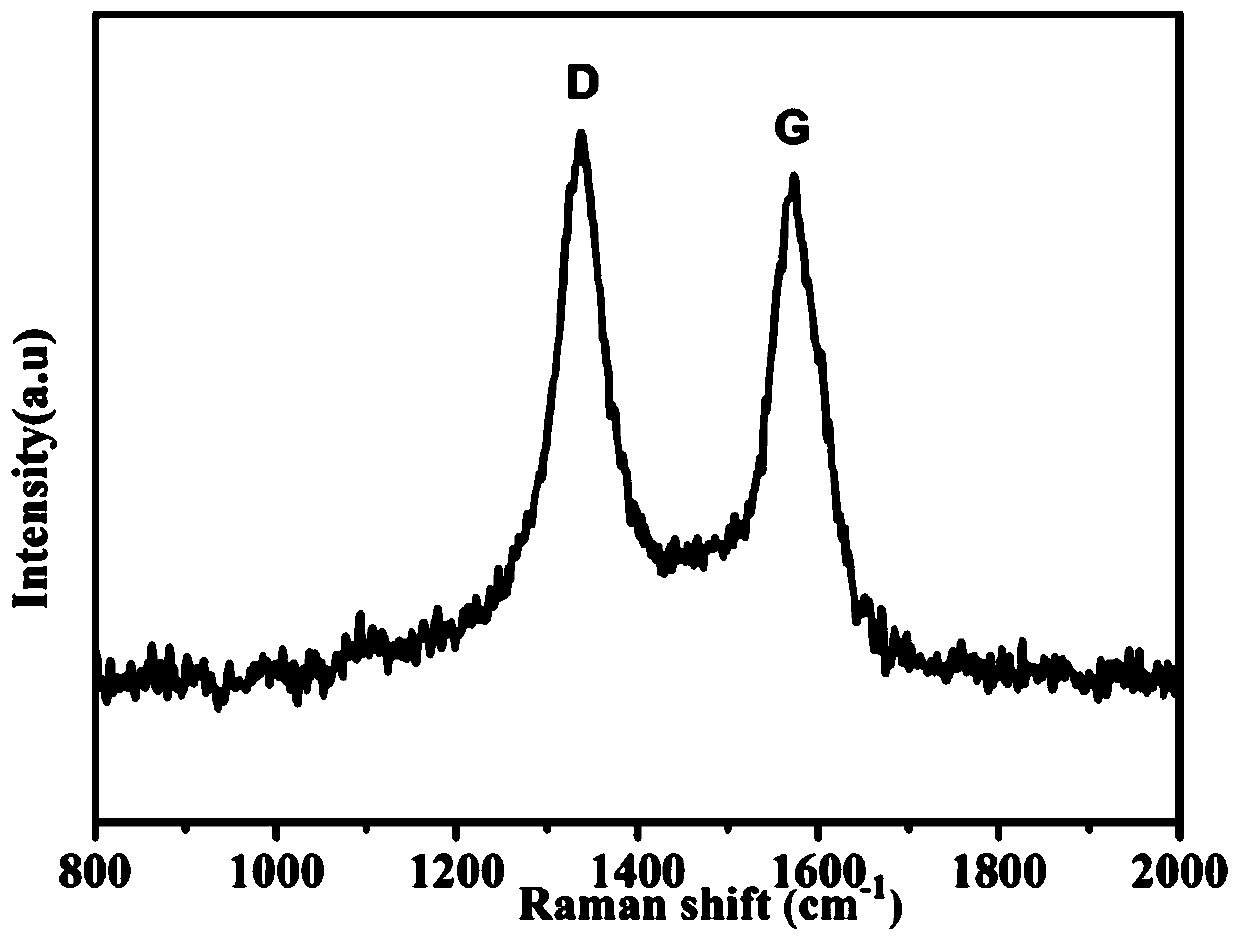

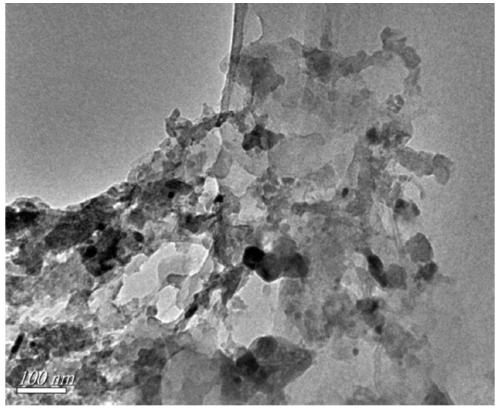

[0033] (1) Weigh 10 g of potassium citrate and put it into a corundum crucible, put the corundum crucible into a tube furnace, calcinate under the protection of an inert gas, raise the temperature to 850°C at a heating rate of 2°C / min, and keep it for 1h. After cooling down to room temperature naturally, the samples were collected by grinding with agate to obtain carbon nanosheets;

[0034] (2) adding the carbon nanomaterials prepared in step (1) to oxidation reaction in 500ml oxidizing acidic solution, the oxidizing acidic solution is configured by volume ratio of 1:1:1 by sulfuric acid, nitric acid and hydrogen peroxide, after the reaction is completed, wash, Wash and centrifuge twice with deionized water and ethanol respectively, and dry in a vacuum oven at 60°C for 12 hours to obtain porous carbon nanosheets;

[0035](3) Weigh 10 mg of the porous carbon nanomaterial prepared in step (2) and 10 mg of sodium dodecylbenzenesulfonate and add it to 200 ml of deionized water, co...

Embodiment 2

[0039] (1) Weigh 12 g of potassium citrate and put it into a corundum crucible, put the corundum crucible into a tube furnace, calcinate under the protection of an inert gas, raise the temperature to 850°C at a heating rate of 2°C / min, and keep it for 1h. After cooling down to room temperature naturally, the samples were collected by grinding with agate to obtain carbon nanosheets;

[0040] (2) Add the carbon nanomaterials prepared in step (1) into 450ml oxidative acidic solution for oxidation reaction. The oxidative acidic solution is configured by sulfuric acid, nitric acid and hydrogen peroxide in a volume ratio of 2:0.5:2. After the reaction, wash , washed and centrifuged twice with deionized water and ethanol respectively, and dried in a vacuum oven at 60°C for 12 hours to obtain porous carbon nanosheets;

[0041] (3) Weigh 20 mg of the porous carbon nanomaterial prepared in step (2) and 10 mg of sodium dodecylbenzenesulfonate and add it to 200 ml of deionized water, cont...

Embodiment 3

[0044] (1) Weigh 8 g of potassium citrate and put it into a corundum crucible, put the corundum crucible into a tube furnace, calcinate under the protection of an inert gas, raise the temperature to 850°C at a heating rate of 2°C / min, and keep it for 1h. After cooling down to room temperature naturally, the samples were collected by grinding with agate to obtain carbon nanosheets;

[0045] (2) Add the carbon nanomaterials prepared in step (1) into 550ml oxidative acidic solution for oxidation reaction, the oxidative acidic solution is configured by sulfuric acid, nitric acid and hydrogen peroxide in a volume ratio of 1:1:1, wash after the reaction , washed and centrifuged twice with deionized water and ethanol respectively, and dried in a vacuum oven at 60°C for 12 hours to obtain porous carbon nanosheets;

[0046] (3) Weigh 10 mg of the porous carbon nanomaterial prepared in step (2) and 20 mg of sodium dodecylbenzenesulfonate and add it to 200 ml of deionized water, continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com