Preparation method and application of Nb-Mo eutectic mesoporous metal oxide catalyst

A catalyst and oxide technology, used in the preparation of metal/metal oxide/metal hydroxide catalysts, organic compounds, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of large catalyst differences and low catalyst repeatability The problem is to achieve the effect of simple preparation method, short preparation period and good catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

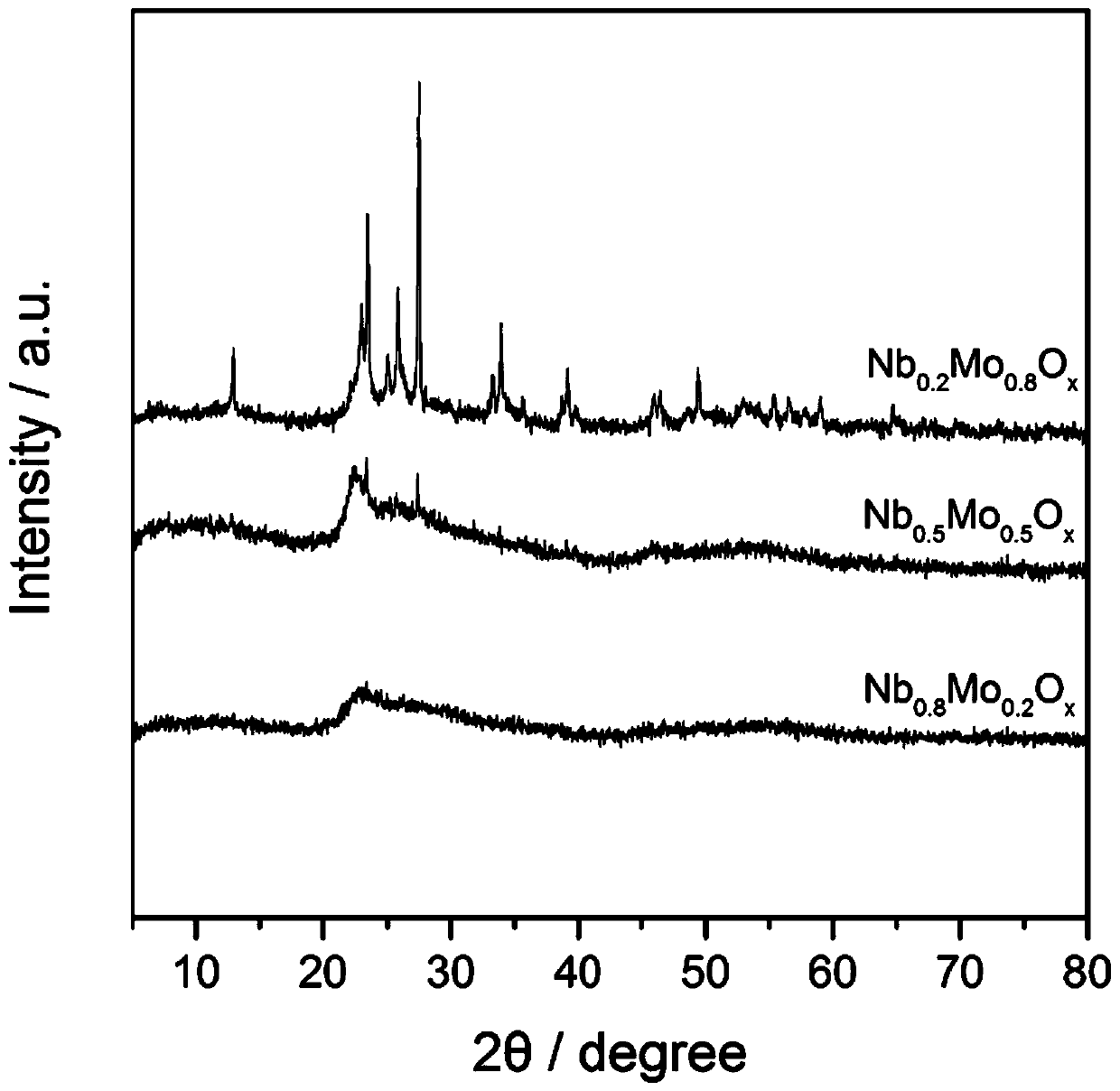

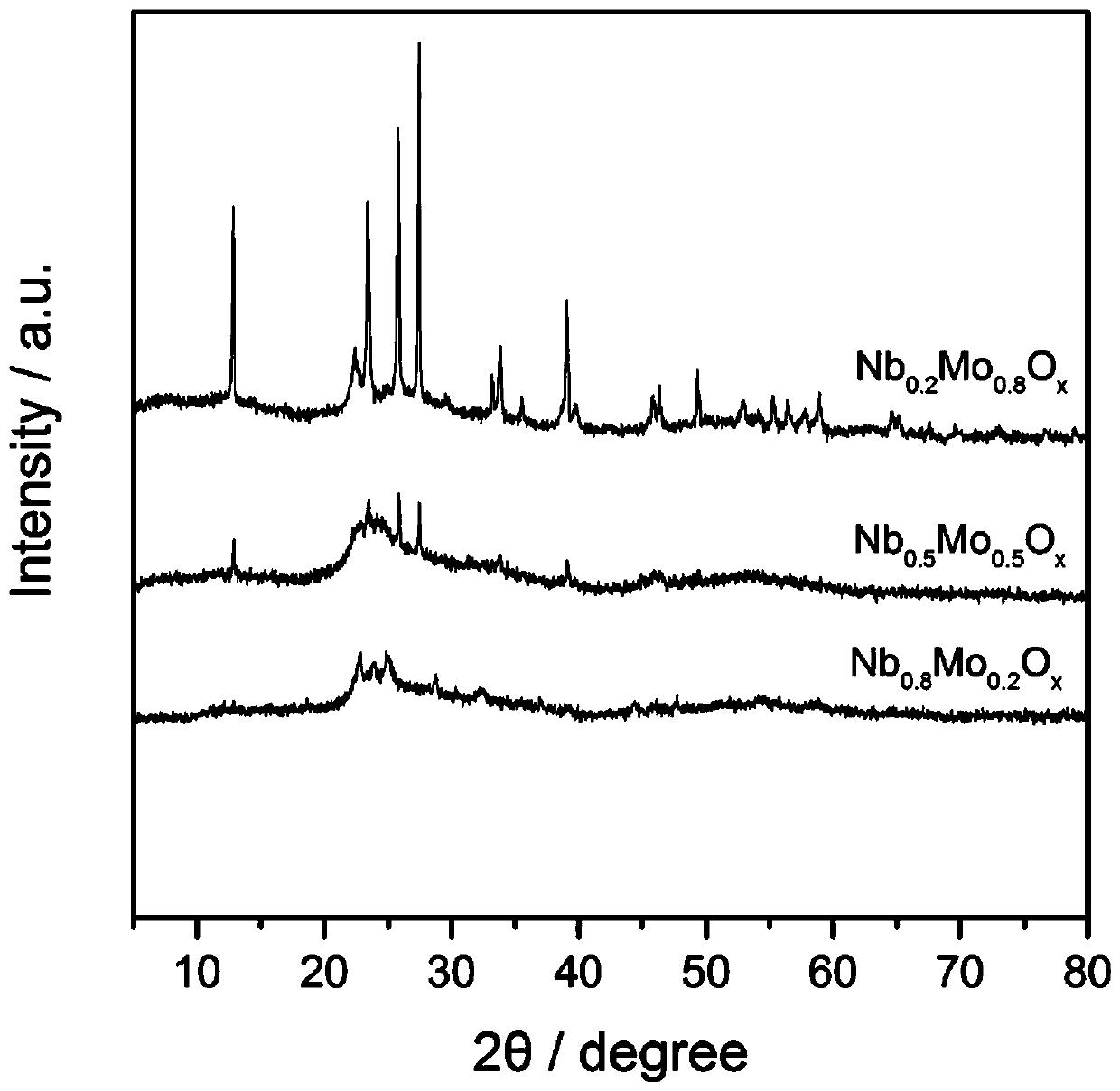

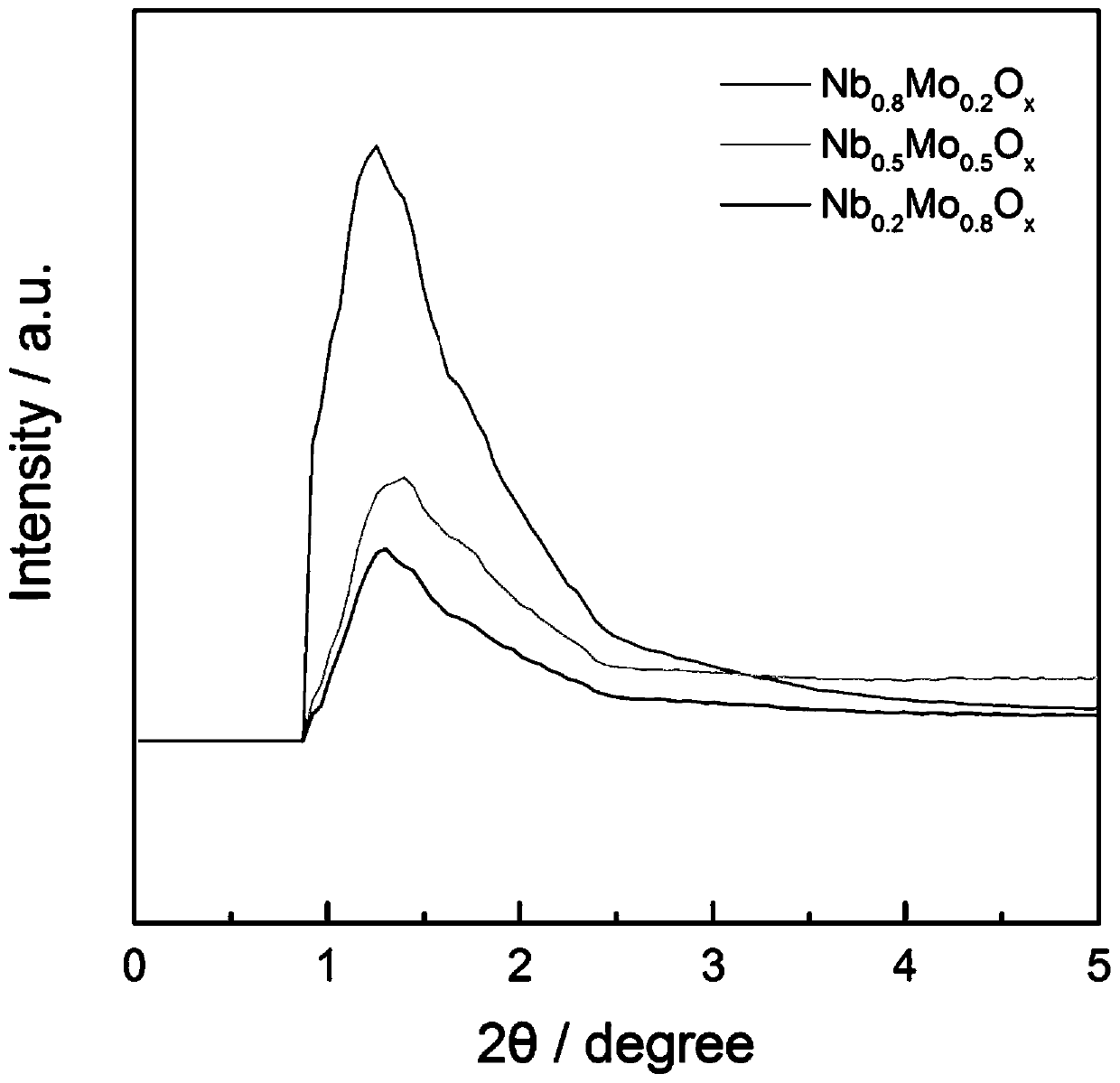

[0036] Embodiment 1: provide a kind of Nb 0.8 Mo 0.2 o x Catalyst preparation method

[0037] a) 7.5g cetyltrimethylammonium bromide was dissolved in 7.5mL H 2 O, stirred at 40°C until completely dissolved. Recorded as solution A.

[0038] b) Weigh 8mmol NbCl 5 (2.161g) and 2mmol MoCl 5 (0.546g), gradually added to 10mL ethanol solution, stirred vigorously for about 10min. Recorded as solution B.

[0039] c) Add the B solution to the A solution dropwise, and further fully stir for about 30 min. This solution is denoted as C solution.

[0040] d) Prepare 10 mL of HCl aqueous solution with pH ≈ 1, and add it to the C solution. This solution is denoted as D solution.

[0041] e) Transfer the D solution to a hydrothermal kettle, and heat it at 160° C. for 24 hours.

[0042] f) After the hydrothermal kettle is lowered to room temperature, the product in the kettle is washed until neutral, and the solid product is separated by suction filtration.

[0043] g) The solid p...

Embodiment 2

[0045] Embodiment 2: provide a kind of Nb 0.5 Mo0.5 o x Catalyst preparation method

[0046] Get 5mmol NbCl in step (b) 5 (1.351g) and 5mmol MoCl 5 (1.366g) was dissolved in ethanol and stirred thoroughly to prepare B solution. All the other steps are the same as in Example 1.

Embodiment 3

[0047] Embodiment 3: provide a kind of Nb 0.2 Mo 0.8 o x Catalyst preparation method

[0048] Get 2mmol NbCl in step (b) 5 (0.540g) and 8mmol MoCl 5 (2.186g) was dissolved in ethanol and stirred thoroughly to prepare B solution. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com