A kind of acidity adjustment method of MFI type molecular sieve

A technology of acidity adjustment and molecular sieve, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problem of uneven distribution of mesopores, achieve uniform distribution of mesopores, stable structure, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The acidity adjustment method of a kind of MFI type molecular sieve that present embodiment provides, comprises:

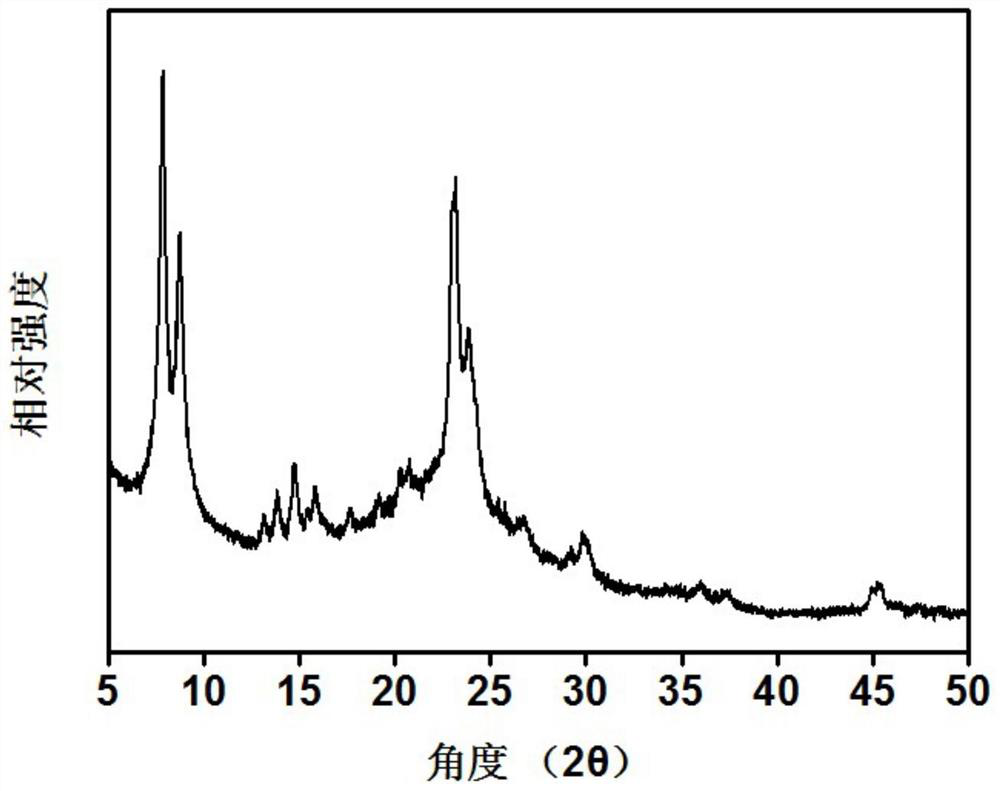

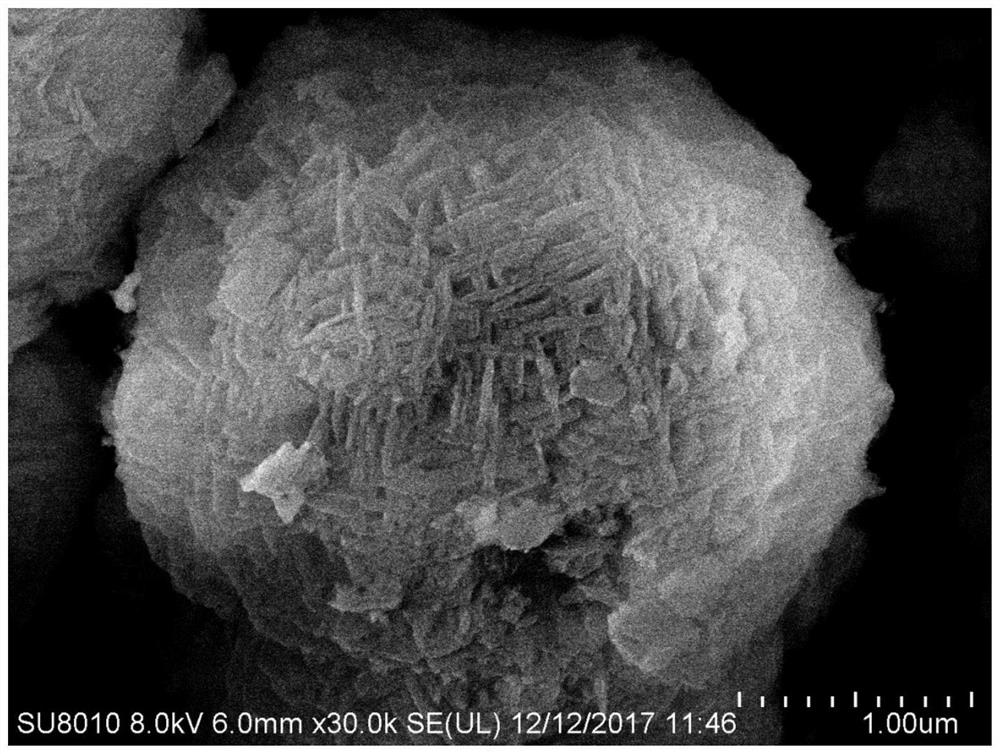

[0033] 1. Preparation of sheet MFI molecular sieves

[0034] With 0.04mol SiO 2 As a benchmark, NaOH, NaAlO 2 , template agent (tetraammonium base head Bola type surfactant C 6-6-12 Br 4 ) and tetraethyl orthosilicate were dissolved in water, stirred at 600rpm magnetically for 30min at room temperature until uniform, and obtained a precursor solution with a molar ratio of 16.28Na 2 O:125SiO 2 :2.0Al 2 o 3 :5C 6-6-12 Br 4 :5000H 2 O: Transfer the precursor solution A to a reaction kettle for crystallization at 150°C for 7 days, filter the reactant, collect the filter residue and dry it in a vacuum oven at 120°C for 10 hours to obtain a sheet MFI molecular sieve.

[0035] The above-mentioned preparation process specifically refers to the following documents:

[0036] B. Liu, Q. Duan, C. Li et al. Template synthesis of the hierarchically structured ...

Embodiment 2

[0042] The acidity adjustment method of a kind of MFI type molecular sieve that present embodiment provides, comprises:

[0043] 1. Preparation of sheet MFI molecular sieves

[0044] This step is the same as that of Embodiment 1, and will not be repeated one by one.

[0045] 2. Preparation of H + Lamellar MFI Molecular Sieve

[0046] The sheet MFI type molecular sieve and 1.2mol / L NH 4 NO 3 The solutions were mixed, and the mixed solution was refluxed at 80°C for 3 times, refluxed for 10 hours each time, then filtered, washed, dried, and roasted to obtain H + Type sheet MFI type molecular sieve. Among them, sheet MFI type molecular sieve and NH 4 NO 3 The mixing mass ratio of the solution is 1:20.

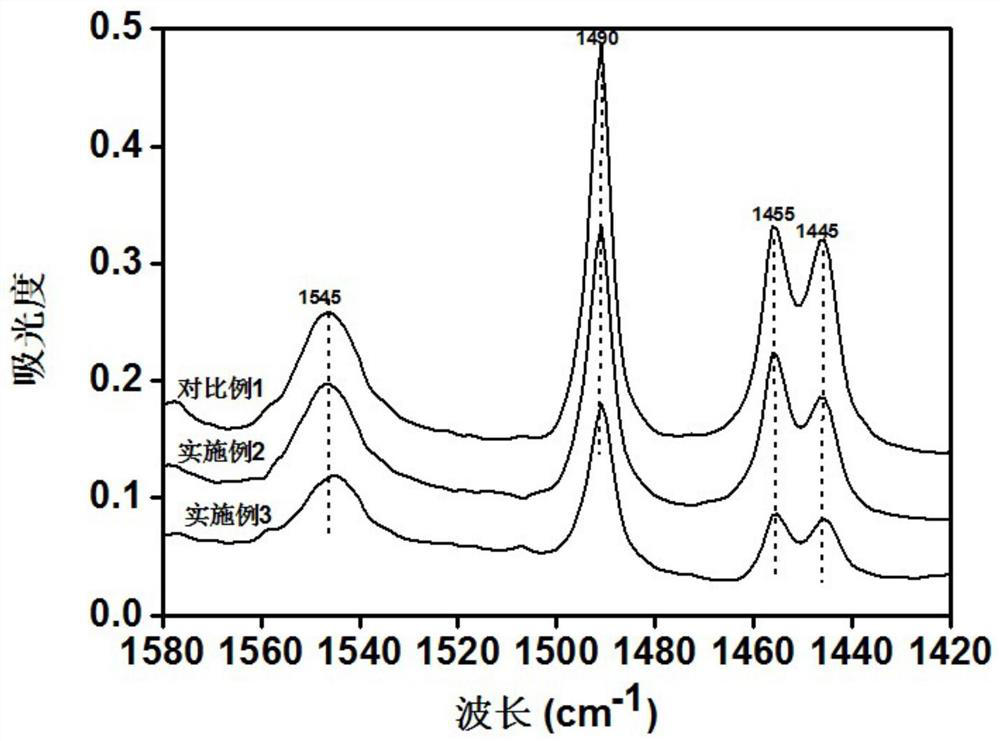

[0047] 3. Acidity adjustment

[0048] Take 1.2g of H + The type sheet MFI molecular sieve was put into a tube furnace and heated to 800 °C at a heating rate of 5 °C / min, and then NH 3 and N 2 The mixed gas (NH 3 Accounting for 10% of the total mixed gas, the total gas ...

Embodiment 3

[0050] The acidity adjustment method of a kind of MFI type molecular sieve that present embodiment provides, comprises:

[0051] 1. Preparation of sheet MFI molecular sieves

[0052] This step is the same as that of Embodiment 1, and will not be repeated one by one.

[0053] 2. Preparation of H + Lamellar MFI Molecular Sieve

[0054] The sheet MFI type molecular sieve and 1.2mol / L NH 4 NO 3 The solutions were mixed, and the mixed solution was refluxed at 80°C for 3 times, refluxed for 10 hours each time, then filtered, washed, dried, and roasted to obtain H + Type sheet MFI type molecular sieve. Among them, sheet MFI type molecular sieve and NH 4 NO 3 The mixing mass ratio of the solution is 1:20.

[0055] 3. Acidity adjustment

[0056] Take 1.2g of H + The type sheet MFI molecular sieve was put into a tube furnace and heated to 800 °C at a heating rate of 5 °C / min, and then NH 3 and N 2 The mixed gas (NH 3 Accounting for 10% of the total mixed gas, the total gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com