porous carbon @pd-al 2 o 3 @ meso tio 2 Microsphere catalyst and its preparation and application

A porous carbon and catalyst technology, applied in the chemical field, can solve the problems of low chemical stability and thermal stability of polymer hollow microspheres, easily damaged structure, large amount of solvent, etc., and achieve good thermal stability and recycling performance , High selectivity, small dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

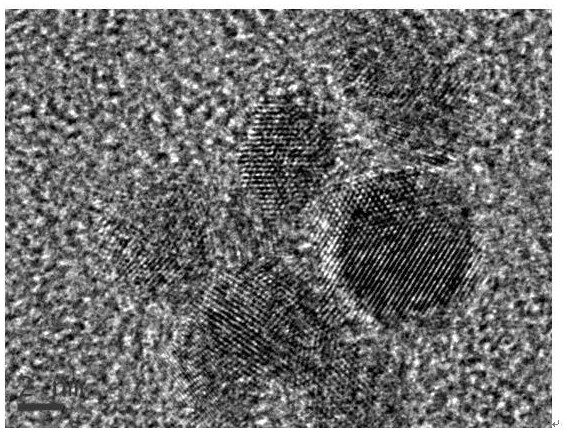

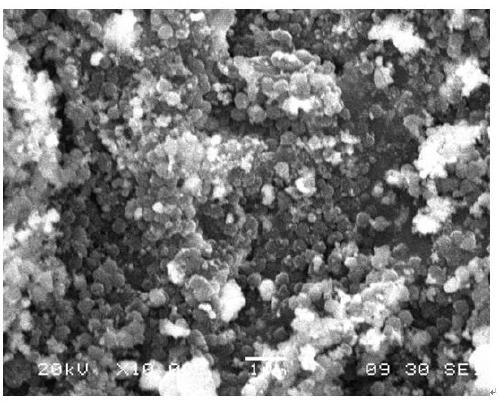

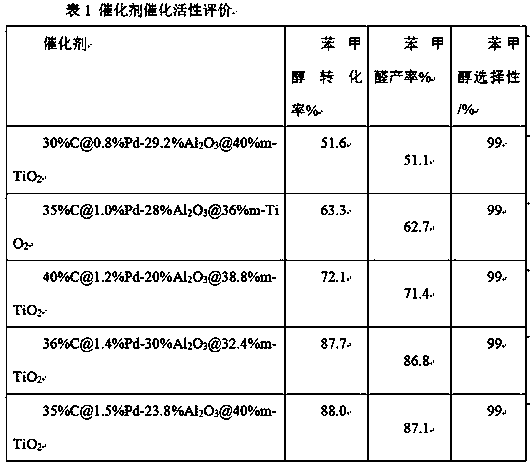

[0019] Example 1. 30%C@0.8%Pd-29.2%Al 2 o 3 @40%m-TiO 2 Preparation of (Pd loading of 0.8%, porous carbon content of 30%, Al 2 o 3 The content is 29.2%, mesoporous TiO 2 content is 40%)

[0020] (1) Dissolve 4 g of glucose in 25 mL of deionized water, add to a 30 mL Teflon-lined hydrothermal kettle, heat at 180°C for 8 hours, centrifuge and wash repeatedly with ethanol until the centrifuged supernatant is colorless, after separating the solution Dry to obtain carbon microspheres. The carbon microspheres were heated to 750 ° C in a tube furnace for 2 h under a nitrogen flow rate of 15 mL / min to form porous carbon microspheres.

[0021] (2) Disperse 0.45g of porous carbon microspheres in 40mL of ethanol, add 5.7mL of 20mmol / L palladium chloride ethanol solution and 1.8g of aluminum isopropoxide, stir at room temperature for 0.5h, heat to 120°C and reflux for 10h , and then concentrate the solution to 25mL, add 10mL of deionized water and stir evenly, then transfer to a 50mL...

Embodiment 2

[0023] Example 2. 35%C@1.0%Pd-28%Al 2 o 3 @36%m-TiO 2 Preparation of (Pd loading 1.0%, porous carbon content 35%, Al 2 o 3 The content is 28%, mesoporous TiO 2 content is 36%)

[0024] (1) Dissolve 4 g of glucose in 25 mL of deionized water, add to a 30 mL Teflon-lined hydrothermal kettle, heat at 180°C for 12 hours, centrifuge and wash repeatedly with ethanol until the centrifuged supernatant is colorless, and separate the solution Dry to obtain carbon microspheres. The carbon microspheres were heated to 780°C in a tube furnace for 2 hours under a nitrogen flow rate of 20mL / min to form porous carbon microspheres.

[0025] (2) Disperse 0.50g of porous carbon microspheres in 40mL of ethanol, add 6.7mL of 20mmol / L palladium chloride ethanol solution and 1.6g of aluminum isopropoxide, stir at room temperature for 0.5h, heat to 120°C and reflux for 10h , and then concentrate the solution to 25mL, add 10mL of deionized water and stir evenly, then transfer to a 50mL polytetra...

Embodiment 3

[0027] Example 3. 40%C@1.2%Pd-20%Al 2 o 3 @38.8%m-TiO 2 Preparation of (Pd loading 1.2%, porous carbon content 40%, Al 2 o 3 The content is 20%, mesoporous TiO 2 content is 38.8%)

[0028] (1) Dissolve 4 g of glucose in 25 mL of deionized water, add to a 30 mL Teflon-lined hydrothermal kettle, heat at 180°C for 16 hours, centrifuge and wash repeatedly with ethanol until the centrifuged supernatant is colorless, after separating the solution Dry to obtain carbon microspheres. The carbon microspheres were heated to 800 ° C in a tube furnace for 2 h under a nitrogen flow rate of 25 mL / min to form porous carbon microspheres.

[0029] (2) Disperse 0.55g of porous carbon microspheres in 40mL of ethanol, add 7.8mL of 20mmol / L palladium chloride ethanol solution and 1.1g of aluminum isopropoxide, stir at room temperature for 0.5h, heat to 120°C and reflux for 10h , and then concentrate the solution to 25mL, add 10mL of deionized water and stir evenly, then transfer to a 50mL po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com