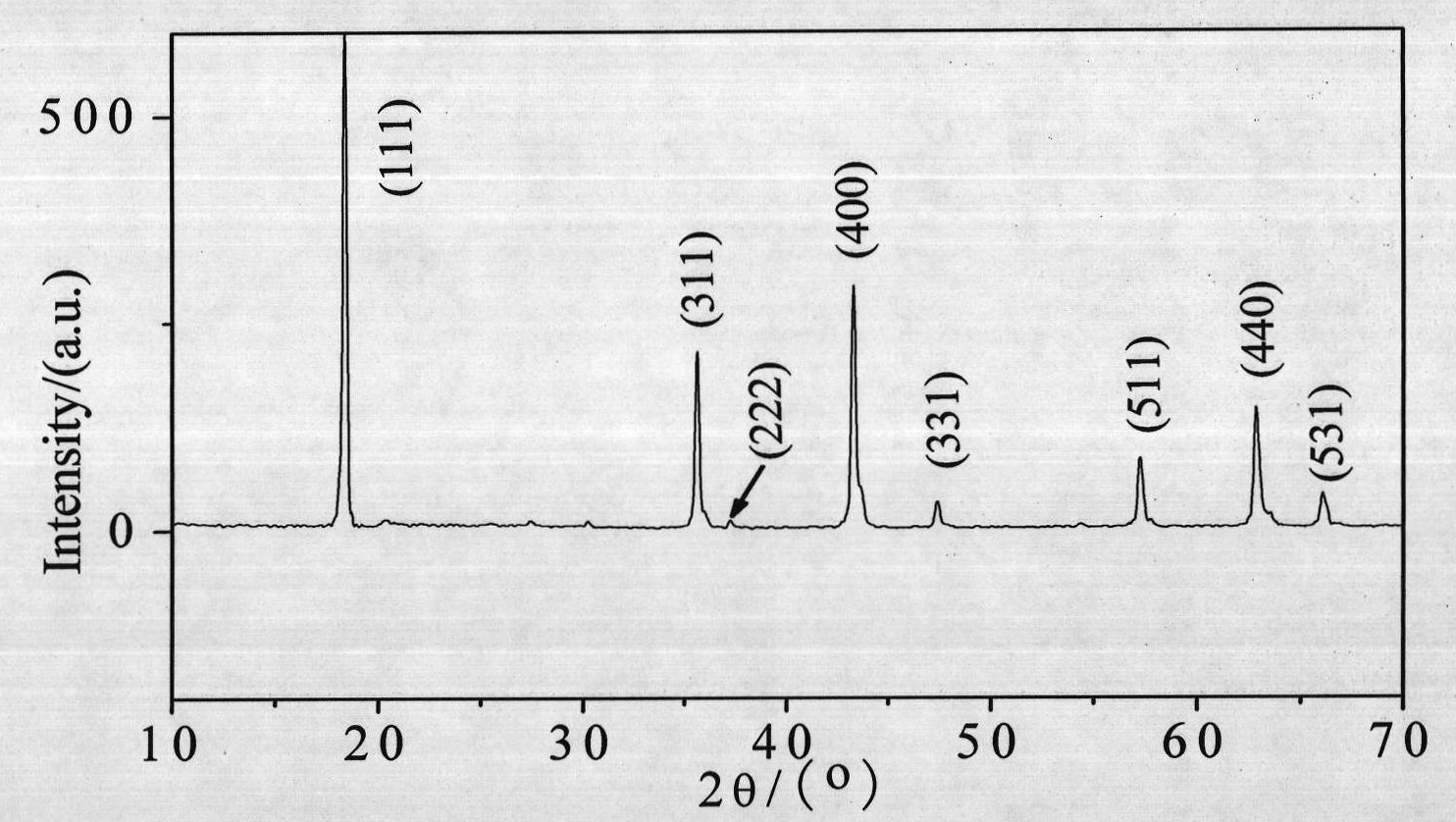

Method for preparing spinel type lithium titanate nanowire array

A nanowire array, spinel-type technology, applied in nanotechnology, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of long ion migration distance, complex preparation process, low utilization rate, etc., and achieve an orderly degree. High, uniform aperture size, adjustable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

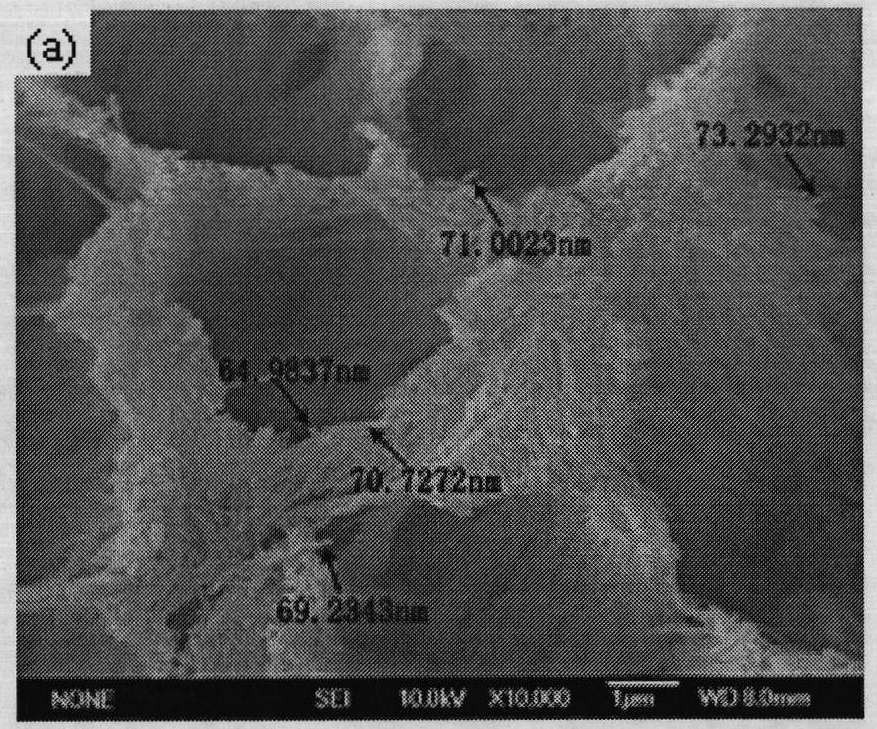

Embodiment 1

[0017] (1) Preparation of porous alumina template. Degrease an aluminum plate with a size of 2cm×2cm×0.5mm and a purity greater than 99.999% with acetone, then anneal at 500°C for 3 hours, in a perchloric acid + ethanol polishing solution with a volume ratio of 1:4, the temperature is 0°C, Electrochemical polishing was carried out at a voltage of 15V for 5 minutes. After polishing, the aluminum plate was anodized for the first time in an electrolyte solution with a concentration of 0.3mol / L oxalic acid. The reaction was carried out at 0°C for 1 hour, and the anodic oxidation voltage was 55V; then the sample was placed in a In the mixed solution of 0.4mol / L phosphoric acid + 0.2mol / L chromic acid, chemically corrode at 70°C for 30 minutes; after that, use the same anodizing conditions as the first time for 4 hours of secondary anodizing; finally , the aluminum plate was treated with 5wt% phosphoric acid solution for 1 hour at room temperature, washed with ultrapure water and dr...

Embodiment 2

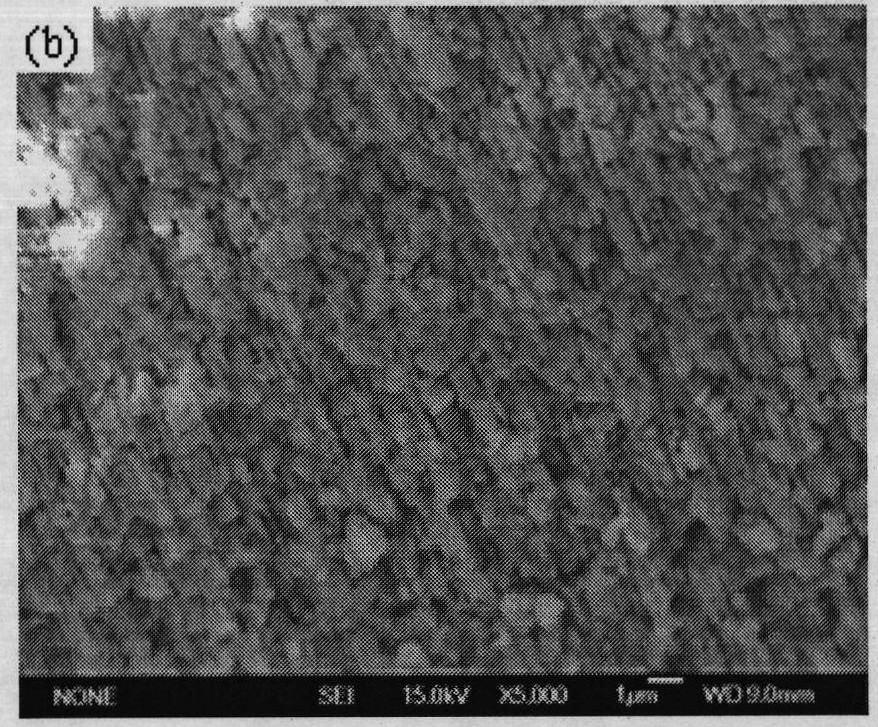

[0022] (1) Preparation of porous alumina template. Degrease an aluminum plate with a size of 2cm×2cm×0.5mm and a purity greater than 99.999% with acetone and anneal at 400°C for 3 hours. Electrochemical polishing was carried out at a voltage of 15V for 5 minutes. After polishing, the aluminum plate was anodized for the first time in an electrolyte solution with a concentration of 0.2mol / L oxalic acid. The reaction was carried out at 10°C for 3 hours, and the anodic oxidation voltage was 60V; then the sample was placed in a In a mixed solution of 0.4mol / L phosphoric acid + 0.2mol / L chromic acid, chemically corrode at 70°C for 30 minutes; then, use the same anodizing conditions as the first time for 5 hours of secondary anodizing; finally , the aluminum plate was treated with 5wt% phosphoric acid solution for 2 hours at room temperature, washed with ultrapure water and dried to obtain a porous alumina template with uniform pore size attached to the pure aluminum plate.

[0023]...

Embodiment 3

[0026] (1) Preparation of porous alumina template. Degrease an aluminum plate with a size of 2cm×2cm×0.5mm and a purity greater than 99.999% with acetone and anneal at 450°C for 3 hours. Electrochemical polishing was carried out at a voltage of 15V for 5 minutes. After polishing, the aluminum plate was anodized for the first time in an electrolyte solution with a concentration of 0.4mol / L oxalic acid. The reaction was carried out at 6°C for 2 hours, and the anodic oxidation voltage was 40V; then the sample was placed in a In the mixed solution of 0.4mol / L phosphoric acid + 0.2mol / L chromic acid, chemically corrode at 70°C for 30 minutes; after that, use the same anodizing conditions as the first time for 6 hours of secondary anodizing; finally , the aluminum plate was treated with 5wt% phosphoric acid solution for 1.5 hours at room temperature, washed with ultrapure water and dried to obtain a porous alumina template with uniform pore size attached to the pure aluminum plate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com