Synthetic method of organic functional mesoporous silicon oxide

A technology of mesoporous silica and synthesis method, applied in the directions of silica, dyed organosilicon compound treatment, silica, etc., can solve the problems of low degree of functionalization, collapse of pores, etc., and achieve excellent performance, increase output, wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

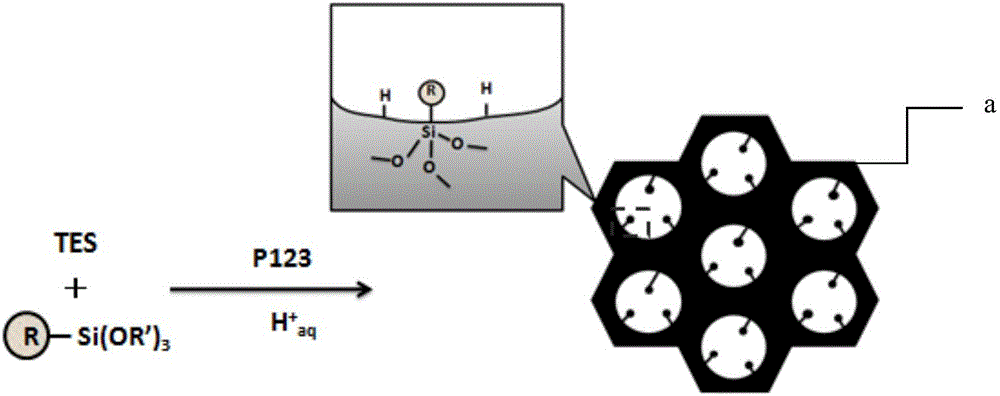

[0031] Example 1: Synthesis of 10% methylated mesoporous hydrogenated silica

[0032] Dissolve 5.0 g of P123 in 200 ml of 0.01 M hydrochloric acid solution at room temperature, and control the speed of the magnetic stirrer at about 450 rpm. The solution was transferred to a 250ml round-bottomed flask, 10g of solid sodium chloride (NaCl) and 5ml of n-butanol were added, and the stirring was continued for 1 hour at a rotation speed of 450rpm. Mix 1.35ml of methyltriethoxysilane and 12.15ml of triethoxysilane evenly, then quickly pour it into the above-mentioned mixed solution, continue to stir for 12 hours, keep the temperature at room temperature at 25°C, and mix the obtained milky white liquid at 9000rpm ( Rotating speed can be adjusted according to the actual situation) After centrifugation, discard the supernatant, transfer the white precipitate to the filter paper tube, and place it in a Soxhlet extractor for extraction for 24 hours to wash away the surfactant, wherein the ...

Embodiment 2

[0033] Example 2: Synthesis of 50% vinylated mesoporous hydrogenated silica

[0034]Dissolve 5.0 g of P123 in 180 ml of 0.1 M hydrochloric acid solution (HCl) at room temperature, and control the speed of the magnetic stirrer at about 450 rpm. The solution was transferred to a 250ml round bottom flask, 9g of solid sodium chloride (NaCl) and 0.5ml of n-butanol were added, and the stirring was continued for 1 hour at a rotation speed of 450rpm. The total amount of silicon source is 13.5ml, and the proportion of vinyltriethoxysilane is 50% of the total amount. Mix 6.75ml of vinyltriethoxysilane and 6.75ml of triethoxysilane evenly, then quickly pour it into the above mixed solution, continue to stir for 16 hours, keep the temperature at room temperature 25°C, and mix the milky white liquid obtained at 9000rpm ( Rotating speed can be adjusted according to the actual situation) After centrifugation, discard the supernatant, transfer the white precipitate to the filter paper tube, ...

Embodiment 3

[0035] Example 3: Synthesis of 80% methylated mesoporous hydrogenated silica

[0036] Dissolve 5.0 g of P123 in 100 ml of 1 M hydrochloric acid solution (HCl) at room temperature, and control the rotation speed of the magnetic stirrer at about 450 rpm. The solution was transferred to a 250ml round bottom flask, 4g of solid sodium chloride (NaCl) and 0.5ml of n-butanol were added, and the stirring was continued for 1 hour at a rotation speed of 450rpm. Adjust the total amount of silicon source to 10 ml, and the proportion of methyltriethoxysilane to be 80% of the total amount. Mix 8ml of methyltriethoxysilane and 2ml of triethoxysilane evenly, then quickly pour it into the above mixed solution, continue to stir for 14 hours, keep the temperature at room temperature 25°C, and mix the milky white liquid obtained at 9000rpm (speed can Adjust according to the actual situation) after centrifugation, discard the supernatant, transfer the white precipitate to a filter paper tube, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com