Ordered mesoporous carbon/tungsten carbide composite material and supported catalyst thereof and preparation method thereof

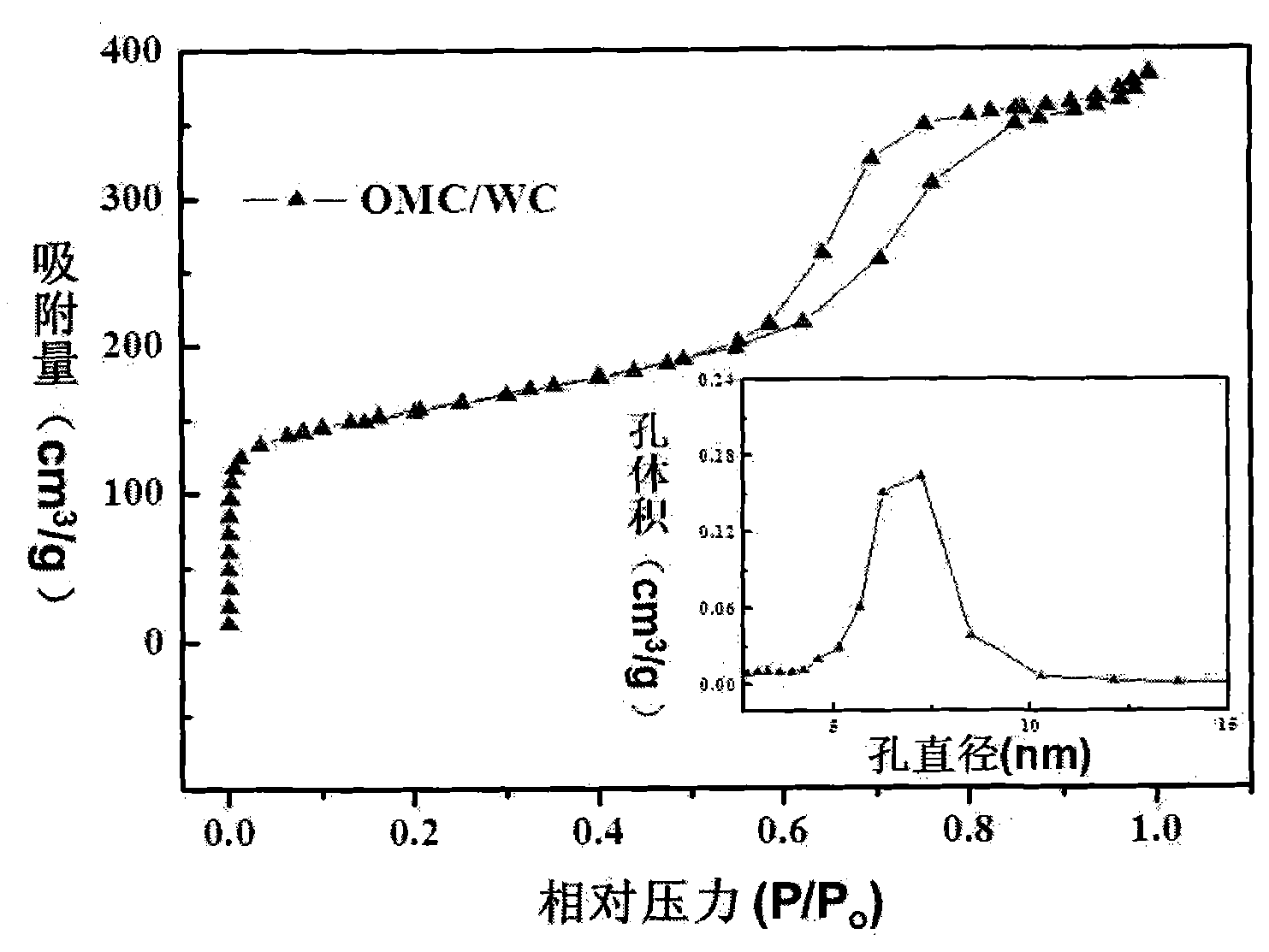

A tungsten carbide composite material and mesoporous carbon technology, applied in the field of material science, can solve the problems of cumbersome steps, high energy consumption, and difficulty in synthesizing orderly openings, and achieve high methanol oxidation catalytic activity, high specific surface area, and pore size distribution narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 6.5g of resorcinol in 10.2mL of formaldehyde, add 1.4mL of 5mol / L sodium hydroxide under stirring, then stir and mix evenly at 70°C for 3 hours, place in the refrigerator, and adjust pH=7 with hydrochloric acid solution And use methanol to prepare 20wt.% resole phenolic resin.

[0031] Add 5.6mL of resole phenolic resin, 0.2g of ammonium metatungstate and 0.5g of surfactant P123 into 15mL of ethanol, and add 5mL of deionized water under vigorous stirring to make the solution uniform. Pour the solution into a petri dish, evaporate to dryness, and dry at 120° C. to obtain a brown-yellow ordered mesoporous carbon / tungsten carbide composite material precursor.

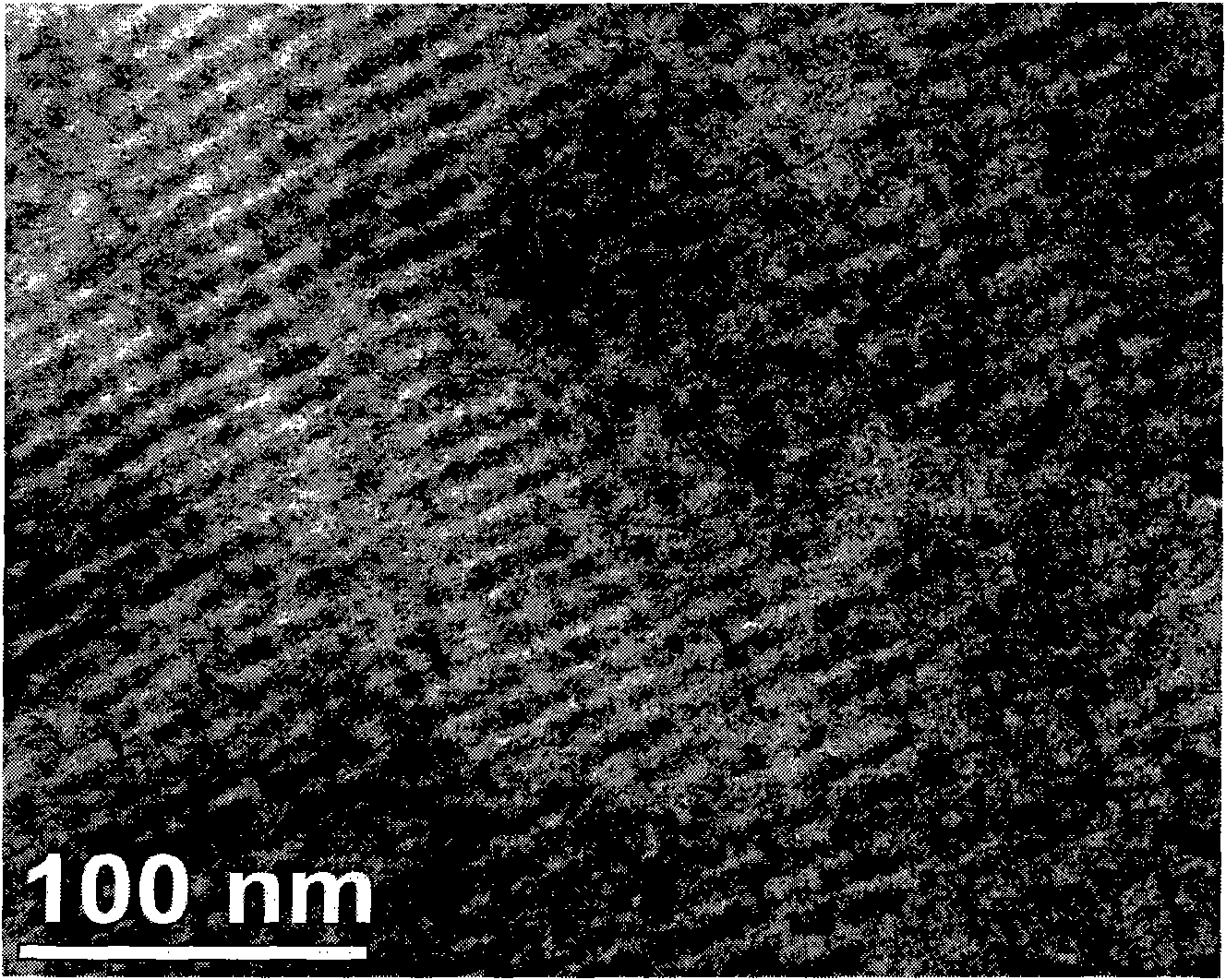

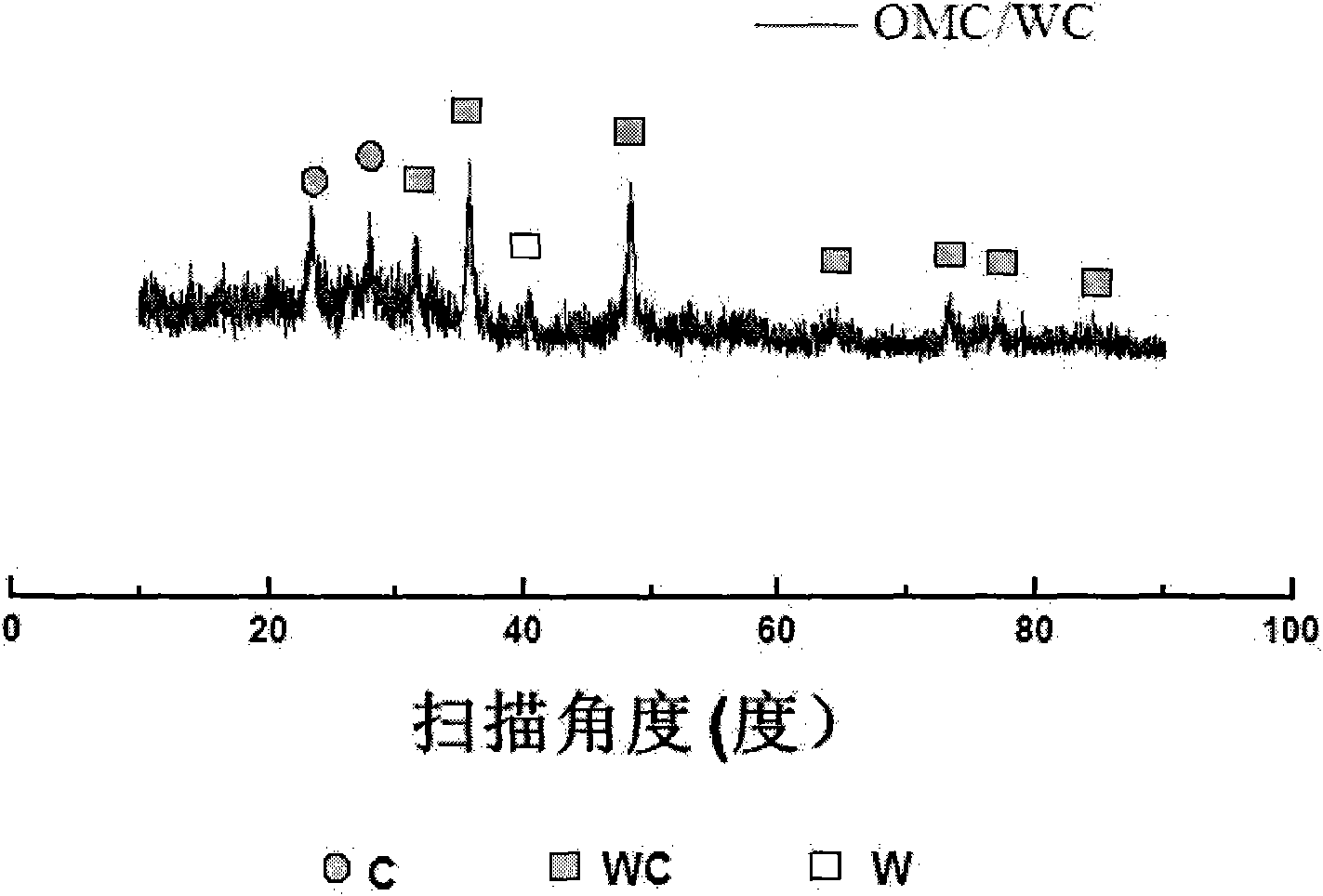

[0032] Put the ordered mesoporous carbon / tungsten carbide composite precursor in a boat, place it in a muffle furnace, and under the protection of argon, heat it up to 800°C at 5°C / min, heat it for 6 hours, and cool it to get a composite material. From figure 1 It can be seen that the prepared samples hav...

Embodiment 2

[0034] Dissolve 6.5g of phenol in 10mL of formaldehyde, add 1.5mL of 5mol / L sodium hydroxide under stirring, then stir and mix evenly at 70°C for 1 hour, place in the refrigerator, adjust pH=7 with hydrochloric acid solution and use ethanol to prepare 20wt.% resole phenolic resin.

[0035] Add 6.0mL of resole phenolic resin, 0.1g of ammonium metatungstate and 1.0g of surfactant F127 into 20mL of ethanol, and add 10mL of deionized water under vigorous stirring to make the solution uniform. Pour the solution into a petri dish, evaporate to dryness, and dry at 100° C. to obtain a brown-yellow ordered mesoporous carbon / tungsten carbide composite material precursor.

[0036] Put the ordered mesoporous carbon / tungsten carbide composite precursor in a boat, place it in a muffle furnace, and under the protection of nitrogen, heat up to 1000°C at 5°C / min, heat it for 2 hours, and cool to obtain ordered mesoporous Carbon / tungsten carbide composite.

Embodiment 3

[0038] Dissolve 7.0g of phenol in 12mL of furfural, add 2.0mL of 6.0mol / L sodium hydroxide under stirring, then stir and mix evenly at 70°C for 3 hours, place in the refrigerator, adjust pH=7 with hydrochloric acid solution and prepare with methanol Into 20wt.% resole phenolic resin.

[0039] Add 5.0mL of resole phenolic resin, 0.3g of ammonium metatungstate and 1.1g of surfactant F127 into 40mL of ethanol, and add 10mL of deionized water under vigorous stirring to make the solution uniform. The solution was poured into a petri dish, evaporated to dryness, and dried at 110° C. to obtain a brown-yellow ordered mesoporous carbon / tungsten carbide composite material precursor.

[0040] Put the ordered mesoporous carbon / tungsten carbide composite precursor in a boat, place it in a muffle furnace, and under the protection of helium, heat up to 1200°C at 2°C / min, heat it for 3 hours, and cool to obtain an ordered mesoporous carbon Porous carbon / tungsten carbide composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com