Mesoporous carbon-tungsten carbide composite material platinum-supporting catalyst preparation method

A composite material, platinum catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of complex preparation method steps, large particle size of tungsten carbide, unfavorable mass production, etc., Achieve the effect of narrow particle size distribution and reduction of agglomeration, which is beneficial to catalytic performance and anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

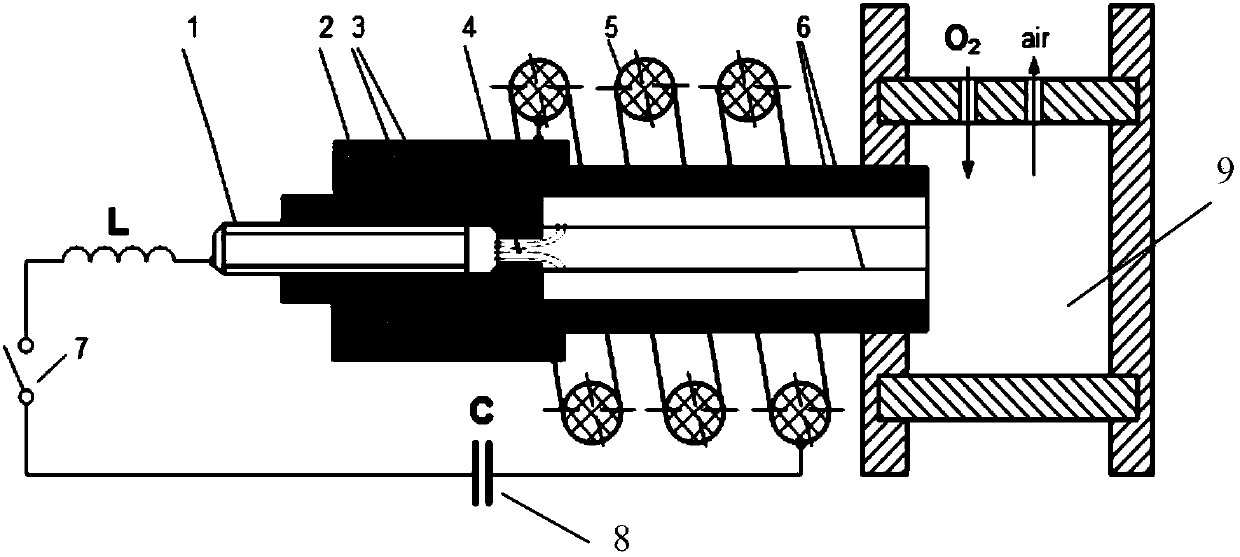

[0025] Embodiment 1 equipment structure

[0026] The structural representation of the preparation system used in the present invention is as follows: figure 1 As shown, its main structure includes a coaxial magnetron plasma accelerator system composed of a non-magnetic metal inner cover 1, a plasma generating device 2, a non-magnetic metal outer cover 3, an accelerator system 4, and an iron electrode sheet 6, and an inductive element system 5, a switch 7. Capacitor 8, reaction chamber 9. Among them, the non-magnetic metal inner cover 1 and the non-magnetic metal outer cover 3 constitute a graphite electrode system, which mainly plays the role of heat dissipation and protection. The maximum charging voltage of the system is 5 kV, and the maximum charging capacitance is 28.8mF. Under the action of the plasma generator 2, the electric current generated by the discharge of the capacitor 8 converts the oxygen into a plasma state, and then the oxygen in the plasma state is acceler...

Embodiment 2

[0027] Example 2 Preparation of mesoporous carbon-tungsten carbide composite supported platinum catalyst

[0028] (1) Preparation of tungsten electrode: Process the commercially available tungsten sheet into the electrode sheet of the magnetron plasma accelerator system device, and then go through the standard semiconductor silicon wafer cleaning process (deionized water, acetone and absolute alcohol, respectively, ultrasonic cleaning for 20 minutes) after cleaning , which is assembled in the coaxial magnetron plasma accelerator system device of embodiment 1 as the tungsten source of the reactant. The system comes with a graphite electrode to provide the carbon source.

[0029] (2) Inflating: After the reaction chamber 9 in the equipment system of Example 1 was evacuated, it was filled with high-purity argon with a purity of 99.99%. After the system pressure returned to 1 atmospheric pressure, the inflation was stopped.

[0030] (3) Plasma heating reaction. The equipment res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com