An inorganic fiber state bismuth compound and application thereof

A bismuth compound and inorganic fiber technology, which is applied in the field of inorganic bismuth compounds, can solve the problems of high density and high shear dissociation, and achieve the effects of uniform size distribution, simple preparation method, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

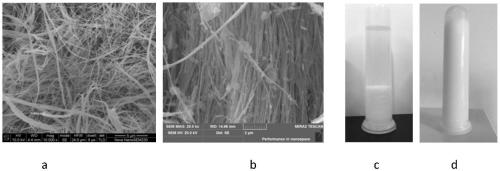

[0046] A kind of preparation method of ordered bismuth compound fiber and colloid thereof of the present embodiment, its specific steps are as follows:

[0047] (1) Mix 8.8g NaCl and 1.6g NaCl 2 CO 3 Dissolve in 70mL containing 1.26g cetyltrimethylammonium chloride (critical micelle concentration 1.6×10 -2 mol / L) in deionized water, the surfactant concentration is 2.52 times of the critical micelle concentration, the pH is adjusted to 3 with 1M HCl solution, and then 7g of Bi with a median diameter of 15 μm is added 2 o 3 The powder was heated to 140° C. in a hydrothermal kettle and kept for 4 hours, and after cooling, it was washed twice with deionization to obtain ordered bismuth subcarbonate nanofibers.

[0048] (2) 0.5 g of octadecylamine was dissolved in 5 mL of ethanol to obtain an ethanol solution of octadecylamine.

[0049] (3) The above prepared (BiO) 2 CO 3 The nanofibers were treated with octadecyl ammonium ethanol solution and re-dispersed in 70mL deionized w...

Embodiment 2

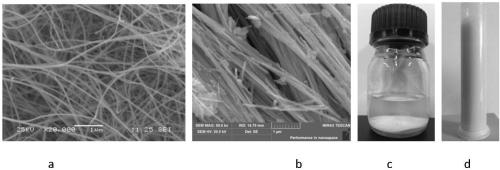

[0051] A kind of preparation method of ordered bismuth compound fiber and colloid thereof of the present embodiment, its specific steps are as follows:

[0052] (1) Weigh 3.65g KCl and 7.6g K 2 SO 4 Dissolve in 70mL potassium oleate (critical micelle concentration 4.5×10 - 3 mol / L) 0.17g in deionized water, the concentration of surfactant is 1.68 times of the critical micelle concentration, and then use H 2 SO 4 (1.0M) adjust its pH to 2.0-3.0, then add 5g of Bi with a median diameter of 2μm 2 o 3 Powder, magnetically stirred at room temperature for 5 minutes, transferred to a polytetrafluoroethylene reactor, stirred and crystallized at 140 ° C for 4 hours;

[0053] (2) 0.5 g of octadecylamine was dissolved in 5 mL of ethanol to obtain an ethanol solution of octadecylamine.

[0054] (3) The above-mentioned hydrothermal product was washed with deionized water for 3 times, then treated with octadecylamine ethanol solution and then dispersed in 70mL of deionized water, add...

Embodiment 3

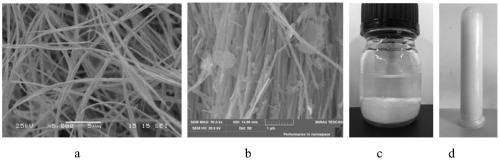

[0056] A kind of preparation method of ordered fiber bismuth compound and colloid thereof of the present embodiment, its specific steps are as follows:

[0057] (1) Dissolve 13.2g NaCl in 70mL containing dodecyltrimethylammonium chloride (critical micelle concentration 1.6×10 - 2 mol / L) 1.08g of deionized water, the surfactant concentration is 3.65 times the critical micelle concentration, adjust the pH to 3 with 1M HCl solution, and then add 7g of Bi with a median diameter of 0.5μm 2 o 3 The powder was heated up to 160° C. in a hydrothermal kettle and kept for 2 hours. After cooling, it was washed twice with deionization to obtain bismuth oxychloride nanofibers.

[0058] (2) 0.5 g of octadecylamine was dissolved in 5 mL of ethanol to obtain an ethanol solution of octadecylamine.

[0059] (3) Add the aforementioned bismuth oxychloride nanofibers to deionized water after being treated with octadecyl ammonium ethanol solution, then add 1g polyvinyl alcohol and 0.5g sodium ole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com