Preparation method of columnar monocrystal nano-TiO2 array film

A technology of single crystal nanometer and titanium oxide, which is applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of many grain boundaries between nanotube particles, improved efficiency of titanium oxide, unfavorable electron transport, etc., to achieve High degree of crystallinity and order, easy operation, and favorable electron transport effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

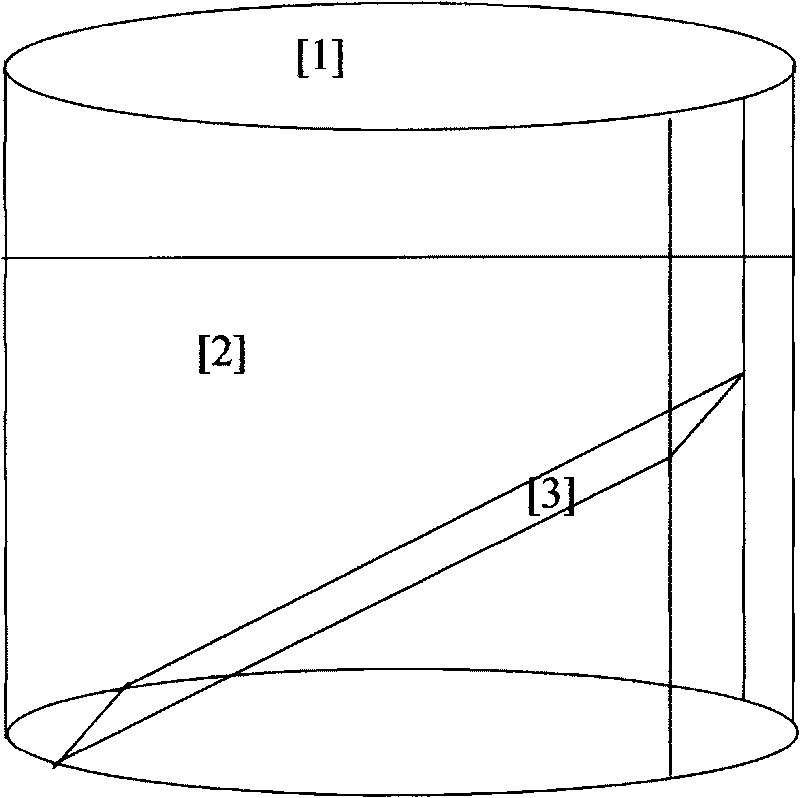

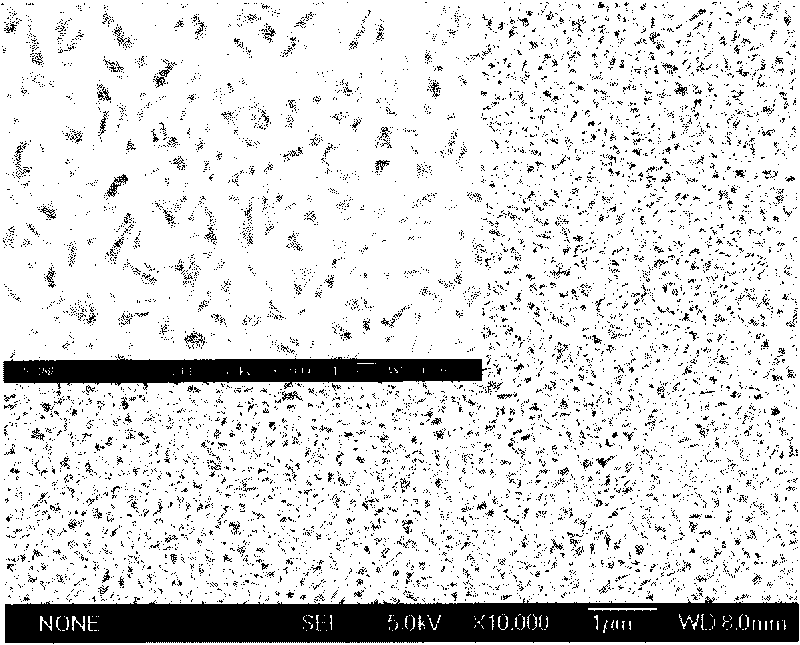

[0027] Mix and stir 30mL of hydrochloric acid and 30mL of deionized water, add 1mL of butyl titanate dropwise while stirring, and pour the mixture of water, hydrochloric acid and butyl titanate into a polytetrafluoroethylene-lined reaction kettle. Clean the conductive glass with a mixed solution of water, acetone and ethanol at a ratio of 1:1:1, and then lean the conductive surface of the glass against the wall of the reaction kettle where the reaction solution is placed. Cover the reactor tightly and place it in a constant temperature oven for 4 hours of hydrothermal treatment at 180°C. After the reaction was completed, the reactor cooled to room temperature was taken out, and the conductive glass was taken out, washed with deionized water and air-dried naturally.

Embodiment 2

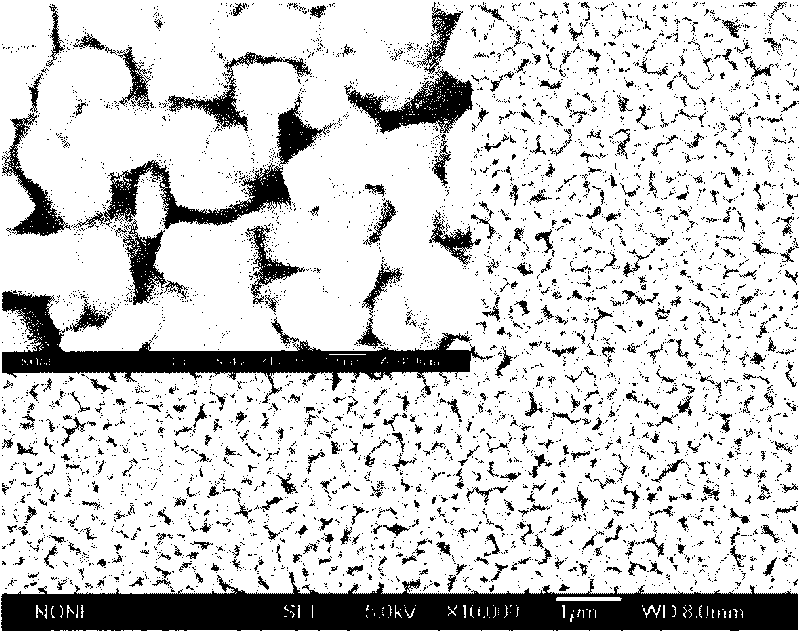

[0029] Mix and stir 30mL hydrochloric acid, 5mL methanol and 25mL deionized water, add 2mL butyl titanate dropwise while stirring, pour the mixture of methanol, water, hydrochloric acid and butyl titanate into polytetrafluoroethylene to react in the cauldron. Clean the conductive glass with a mixed solution of water, acetone and ethanol in a ratio of 1:1:1, and then lean the conductive surface of the glass against the wall of the reaction kettle with the reaction solution, and immerse the conductive glass in the solution. Cover the reactor tightly and place it in a constant temperature oven for 6 hours of hydrothermal treatment at 160°C. After the reaction was completed, the reactor cooled to room temperature was taken out, and the conductive glass was taken out, washed with deionized water and air-dried naturally.

Embodiment 3

[0031] Mix and stir 30mL hydrochloric acid, 10mL ethanol and 20mL deionized water, add 4mL butyl titanate dropwise while stirring, pour the mixture of ethanol, water, hydrochloric acid and butyl titanate into the polytetrafluoroethylene Lining the reactor. Clean the conductive glass with a mixed solution of water, acetone and ethanol at a ratio of 1:1:1, and then lean the conductive surface of the glass against the wall of the reaction kettle where the reaction solution is placed. Cover the reactor tightly and place it in a constant temperature oven for 8 hours of hydrothermal treatment at 150°C. After the reaction was completed, the reactor cooled to room temperature was taken out, and the conductive glass was taken out, washed with deionized water and air-dried naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com