Organic-inorganic hybrid mesoporous catalyst for purifying VOCs (volatile organic compounds) and method for preparing organic-inorganic hybrid mesoporous catalyst

A catalyst and inorganic technology, applied in the field of organic-inorganic hybrid mesoporous catalyst and its preparation, can solve the problems of easy volatilization and sintering of active components, high complete conversion temperature, low light-off temperature, etc. Catalytic performance, uniform distribution of functional groups, and not easy to deactivate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

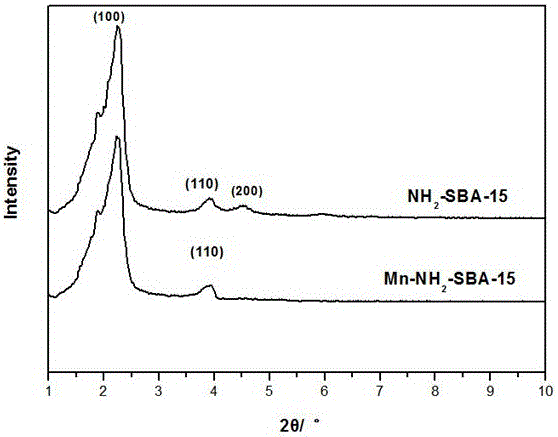

Image

Examples

Embodiment 1

[0039] (1) Mix 1.0g of surfactant triblock copolymer P123, 50mL of 1.0mol / L KCl solution, 120mL of 2mol / L hydrochloric acid solution, and 30mL of absolute ethanol, and stir until clear at room temperature to fully dissolve the solid .

[0040] (2) Then add 1g of 1,3,5-trimethylbenzene (TMB) and stir magnetically at 40°C for 30 minutes, then add 4g of tetraethyl orthosilicate (TEOS) and 1mmol of phenyltriethoxysilane in sequence, and use ultrasonic Vibration assisted mechanical stirring for 1h.

[0041] (3) The reaction solution obtained in step (2) was transferred to an autoclave for crystallization at 100°C for 24 hours.

[0042] (4) Suction filter the reaction product obtained in step (3), wash with distilled water at a temperature of 60°C, and vacuum-dry at 60°C for 6 hours. / V (concentrated hydrochloric acid) = 50, concentrated hydrochloric acid (36wt%)) was refluxed for 12 hours, repeated twice, and washed twice with absolute ethanol, dried in vacuum at 60°C for 6 hour...

Embodiment 2

[0046] (1) Mix 3g of surfactant triblock copolymer P123, 80mL of 1.0mol / L NaCl solution, 50mL of 2mol / L hydrochloric acid solution, and 50mL of absolute ethanol, and stir until clear at room temperature to fully dissolve the solid.

[0047] (2) Then add 0.5g of 1,3,5-trimethylbenzene (TMB) and stir magnetically at 40°C for 60 minutes, then add 5g of tetraethyl orthosilicate (TEOS) and 1.5mmol of aminopropyltriethoxysilane in sequence , using ultrasonic vibration to assist mechanical stirring for 2h.

[0048] (3) The reaction solution obtained in step (2) was transferred to an autoclave for crystallization at 100°C for 24 hours.

[0049] (4) Suction filter the reaction product obtained in step (3), wash with distilled water at a temperature of 60°C, and vacuum-dry at 70°C for 4 hours. / V (concentrated hydrochloric acid) = 50, concentrated hydrochloric acid (38wt%)) was refluxed for 12 hours, repeated twice, and washed twice with absolute ethanol, dried in vacuum at 70°C for 4...

Embodiment 3

[0053] (1) Mix 5.0g of surfactant triblock copolymer P123, 65mL of 1.0mol / L KCl solution, 85mL of 2mol / L hydrochloric acid solution, and 40mL of absolute ethanol, stir until clear at room temperature, and fully dissolve the solid .

[0054] (2) Then add 0.75g of 1,3,5-trimethylbenzene (TMB) and stir magnetically at 40°C for 45 minutes, then add 5g of tetraethyl orthosilicate (TEOS), 1.25mmol of mercaptopropyltrimethoxysilane, Mechanical stirring was assisted by ultrasonic vibration for 1 h.

[0055] (3) The reaction solution obtained in step (2) was transferred to an autoclave for crystallization at 150°C for 12 hours.

[0056] (4) Suction filter the reaction product obtained in step (3), wash with distilled water at a temperature of 80°C, and vacuum-dry at 80°C for 4 hours. / V (concentrated hydrochloric acid) = 50, concentrated hydrochloric acid (37wt%)) was refluxed for 12 hours, repeated twice, and washed twice with absolute ethanol, dried in vacuum at 80°C for 4 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com