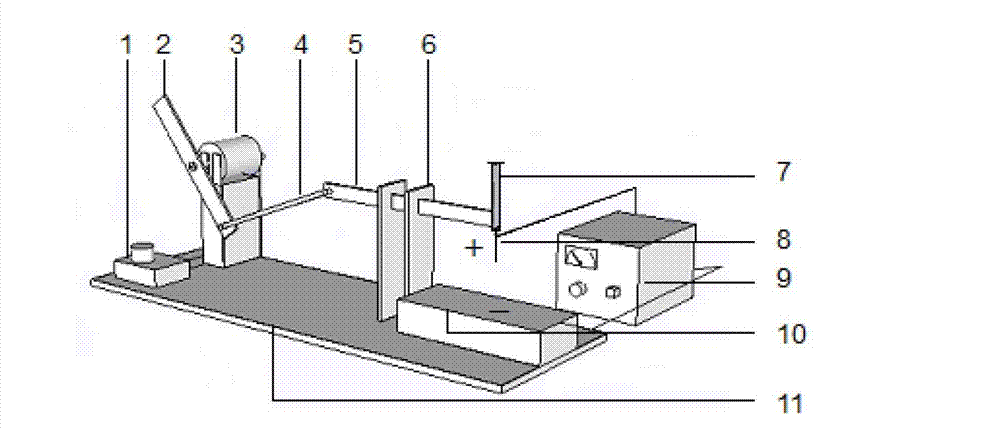

Electrostatic spinning device with spinning nozzle capable of doing linear reciprocating motion

A reciprocating straight line, electrospinning technology, applied in filament/thread forming, textile and papermaking, bundling of newly ejected filaments, etc. The effect of low operating voltage and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

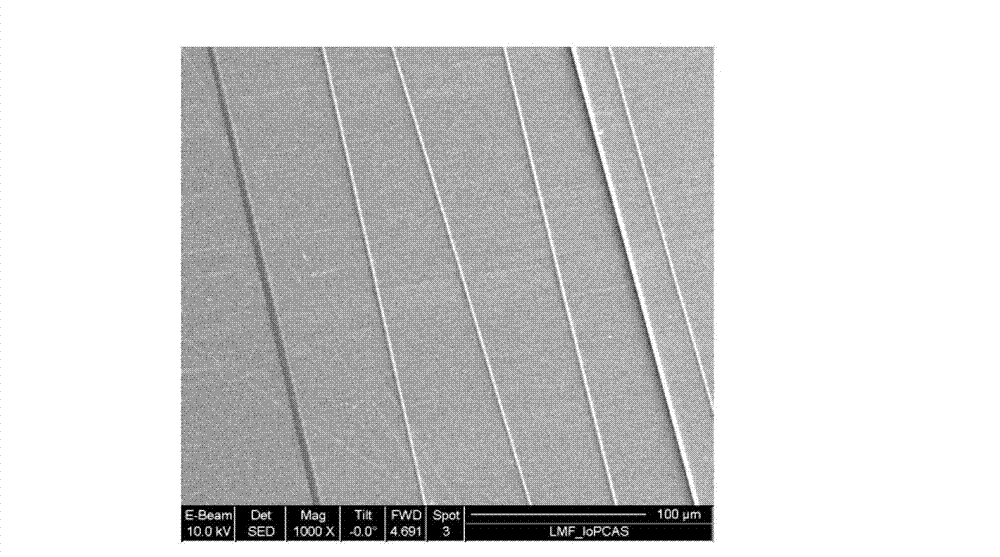

Embodiment 1

[0017] Example 1: Preparation of PVP fibers with a linear structure in an orderly arrangement: Use a disposable straw to extract about 1 milliliter of PVP precursor solution and inject it into the syringe needle tube 7 for spinning. 10. Adjust the distance between the stainless steel needle 8 and the aluminum foil collector 10 to 1 cm, put a glass slide on the collector, cover the glass slide with a piece of clean and dry paper, and connect the high-voltage DC power supply 9 to make The switch is in the "ON" state, the voltage is adjusted to 1.8 kV, and the stationary needle starts spinning; the power supply of the brushless DC motor 3 is turned on, and the knob of the governor 1 is rotated so that the rotating speed is 200rpm, and the stationary needle starts spinning. Reciprocating linear motion, after a few seconds of stable speed, quickly remove the paper covering the cover glass, and start timing, after 15 seconds, turn off the high-voltage DC power supply 9, make its swit...

Embodiment 2

[0018]Example 2: Preparation of cross-structured PVP fibers: first prepare orderly arranged PVP fibers according to the steps in Example 1, then rotate the collected samples by 90° and repeat the electrospinning once again with the same conditions and steps to obtain The optical microscope photos of the cross-structured PVP fibers are as follows image 3 shown.

Embodiment 3

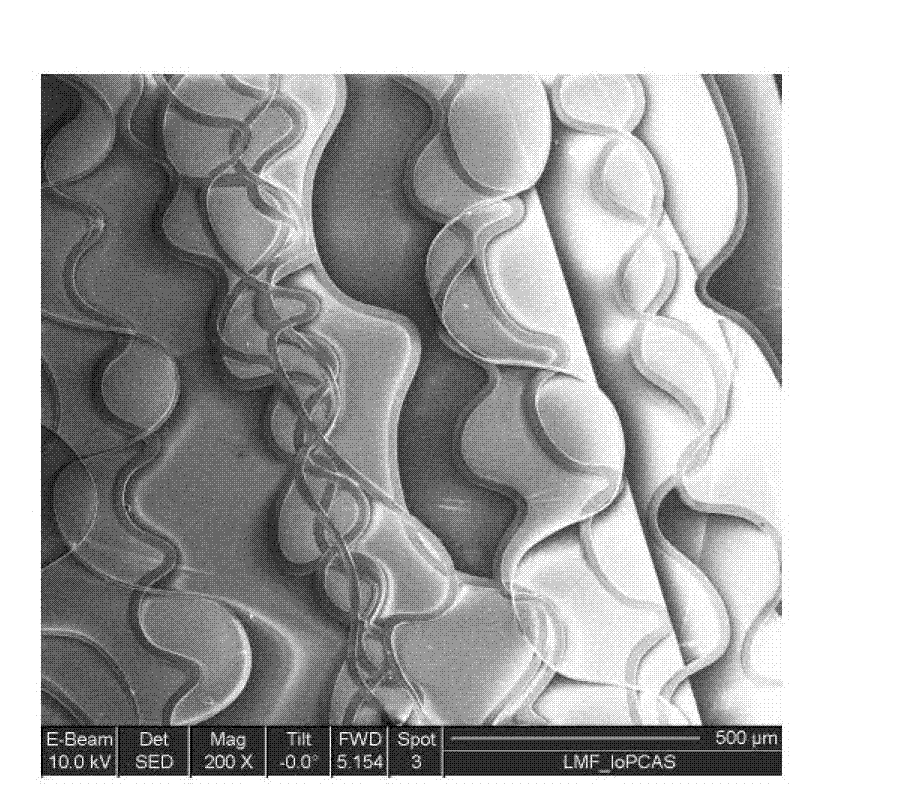

[0019] Embodiment 3: the preparation of the PVP fiber of orderly arrangement distorted structure: adjusting the voltage among the embodiment 1 is 3.5 kilovolts, other steps are constant, finally obtain the PVP fiber of orderly arrangement distorted structure, the SEM photo of its sample is as follows Figure 4 As shown, it can be seen that the prepared fibers have a twisted structure and are arranged in an orderly manner, but due to the distribution of wave-shaped fibers on a two-dimensional scale, there is an intercrossing phenomenon between the fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com