Preparation method for heteratom-containing ordered mesoporous carbon with high specific capacitance

A technology with high specific capacitance and heteroatoms, which is applied in the field of mesoporous carbon preparation, can solve the problems of difficult control of the physical structure and surface chemical structure of mesoporous carbon, low specific surface area of mesoporous carbon, and long synthesis cycle, etc. Large-scale production, high specific capacitance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

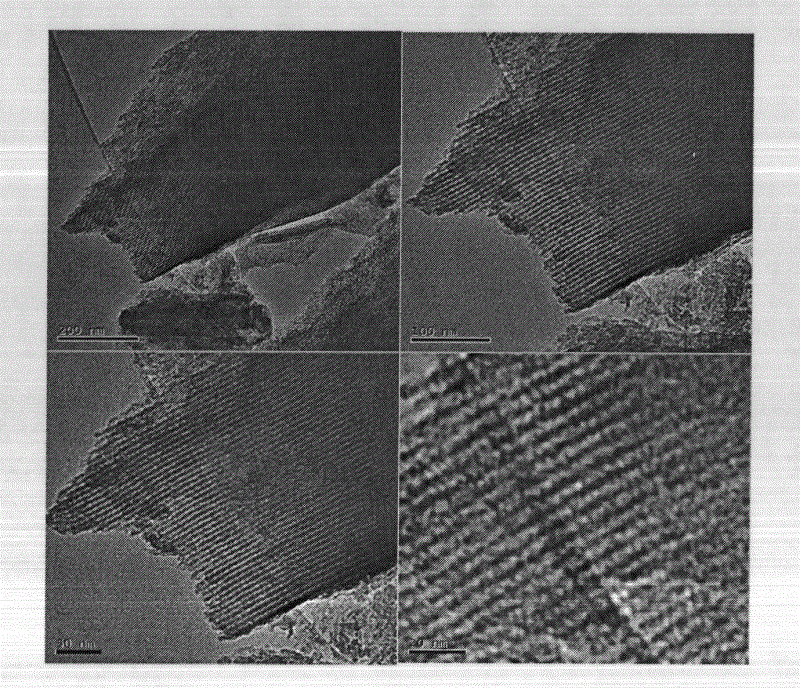

Image

Examples

Embodiment 1

[0031] Melt 4.2g of phenol and add 30wt% Na 2 CO 3 0.5g aqueous solution, stirred for 10min, added 5.0g of 37wt% formaldehyde aqueous solution, reacted at 72°C for 30min, added 0.3g of ammonium phosphate, and continued to react for 40min. Adjust the pH of the solution to 7, and dehydrate under reduced pressure for 1 h. The resulting resin was dissolved in tetrahydrofuran.

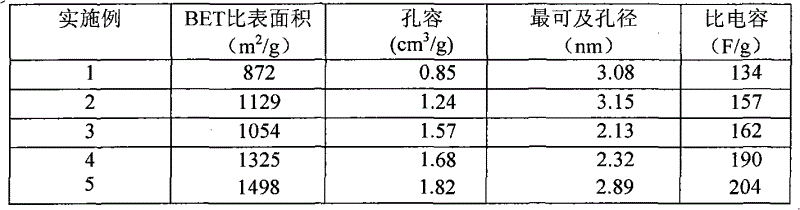

[0032] Dissolve 1.0g of F127 in tetrahydrofuran, add 0.9g of silica sol and stir for 2h, then add 4.0g of tetrahydrofuran solution of phosphorus-containing phenolic resin, stir for 10min, transfer to a petri dish to evaporate the solvent for 6h, and solidify at 100°C for 48h. Carbonization at 900°C for 1h under an inert atmosphere. The carbonized sample was treated with hydrofluoric acid to remove silicon, washed and dried to obtain phosphorus-containing ordered mesoporous carbon, and the properties of mesoporous carbon are shown in Table 1.

Embodiment 2

[0034] Melt 8.5g of phenol, add 2.6g of 20wt% NaOH aqueous solution, stir for 30min, add 9.0g of 37wt% formaldehyde aqueous solution, react at 78°C for 20min, add 0.8g of phosphoric acid, and continue the reaction for 60min. Adjust the pH value of the solution to 9, and distill under reduced pressure for 2 h. The resulting resin was dissolved in ethanol.

[0035] Dissolve 1.8g of HD2018 in ethanol, add 2.0g of TEOS and stir for 1h, then add 5.0g of ethanol solution of phosphorus-containing phenolic resin, stir for 30min, transfer to a petri dish to evaporate the solvent for 8h, and solidify at 120°C for 18h. Carbonization at 800°C for 3h under an inert atmosphere. The carbonized sample was treated with 30wt% NaOH solution to remove silicon, and after washing and drying, ordered mesoporous carbon containing phosphorus was obtained. The properties of mesoporous carbon are shown in Table 1.

Embodiment 3

[0037] Melt 5.8g of phenol, add 0.4g of concentrated ammonia water, stir for 20min, add 4.5g of 37wt% formaldehyde solution, react at 85°C for 40min, add 0.8g of melamine, and continue to react for 20min. Adjust the pH value of the solution to 8, and distill under reduced pressure for 1 h. The resulting resin was dissolved in ethanol.

[0038] Dissolve 1.5g of P123 in ethanol, add 1.5g of TEOS and stir for 1.5h, then add 5.0g of ethanol solution of nitrogen-containing phenolic resin, stir for 40min, transfer to a petri dish to evaporate the solvent for 10h, and solidify at 150°C for 12h. Carbonization at 1100°C for 0.5h under an inert atmosphere. The carbonized sample was treated with 35wt% NaOH solution to remove silicon, washed and dried to obtain nitrogen-containing ordered mesoporous carbon. The properties of mesoporous carbon are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com