Nano grade titanium silicon molecular sieve and its synthesis technology

A titanium-silicon molecular sieve, nano-scale technology, used in the field of environmental protection and applied chemistry, can solve the problems of low ion exchange capacity, poor thermal stability and radiation resistance, and achieve high exchange capacity, thermal stability and radiation resistance Good lighting performance and reduced synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

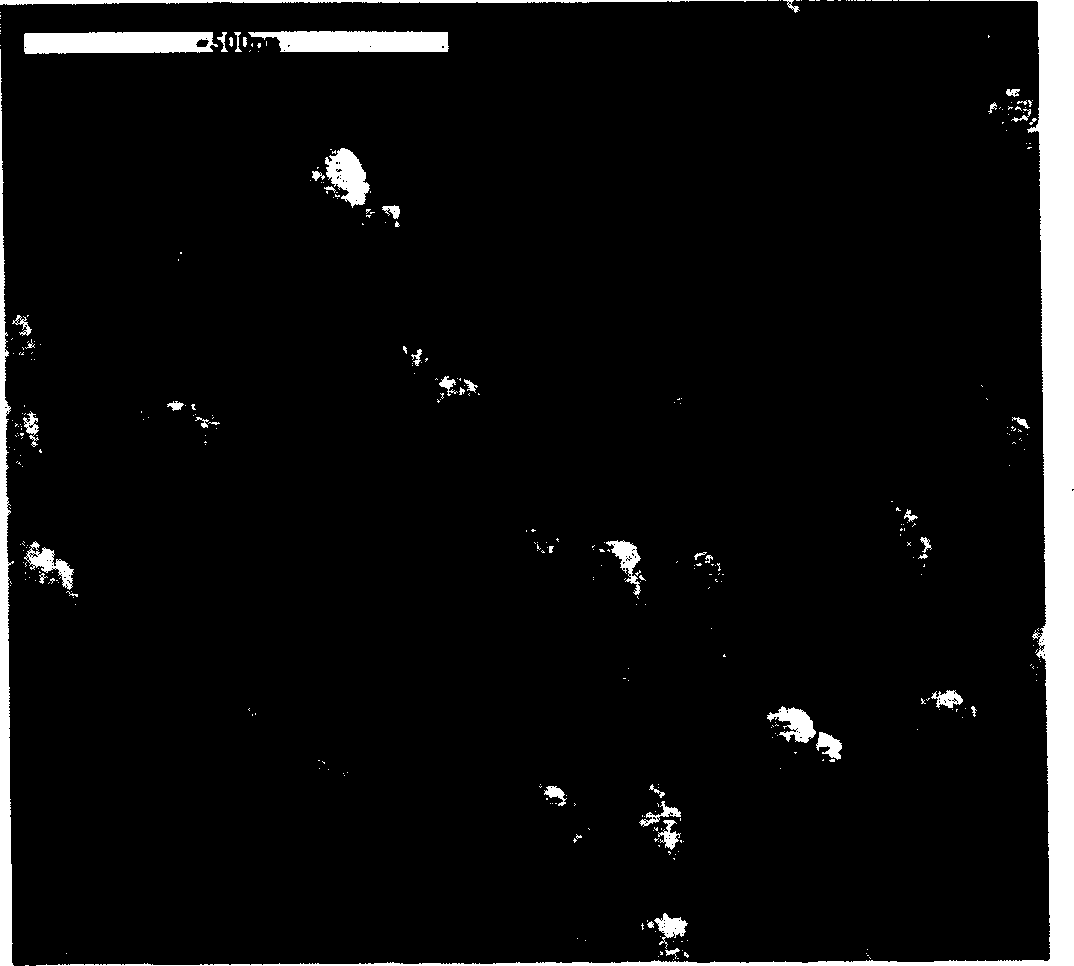

[0032] Add 6% sodium hydroxide to 76% water, under continuous stirring, first add 8% tetraisopropyl titanate dropwise to the aqueous solution of sodium hydroxide, then add 10% tetraethyl orthosilicate in 0.06ml / s speed dropwise into the mixture to obtain a white colloid. Then the colloid was transferred to a simple high-pressure reactor, and the hydrothermal reaction was carried out at a temperature of 190° C. for 4 days. The obtained solid product was washed with acetone and deionized water respectively, centrifuged and dried in an oven to obtain the desired sample.

[0033] Atomic absorption spectrometry (AAS) was used to determine the concentration of the sample in 0.1M HNO 3 , In an aqueous solution of 100ppm cesium, the distribution coefficient of cesium can be as high as 36500ml / g; in an aqueous solution of 0.1M NaOH and 100ppm strontium, the distribution coefficient of strontium can be as high as 9000ml / g; in an aqueous solution of 0.1M NaOH and 100ppm lithium , the ...

Embodiment 2

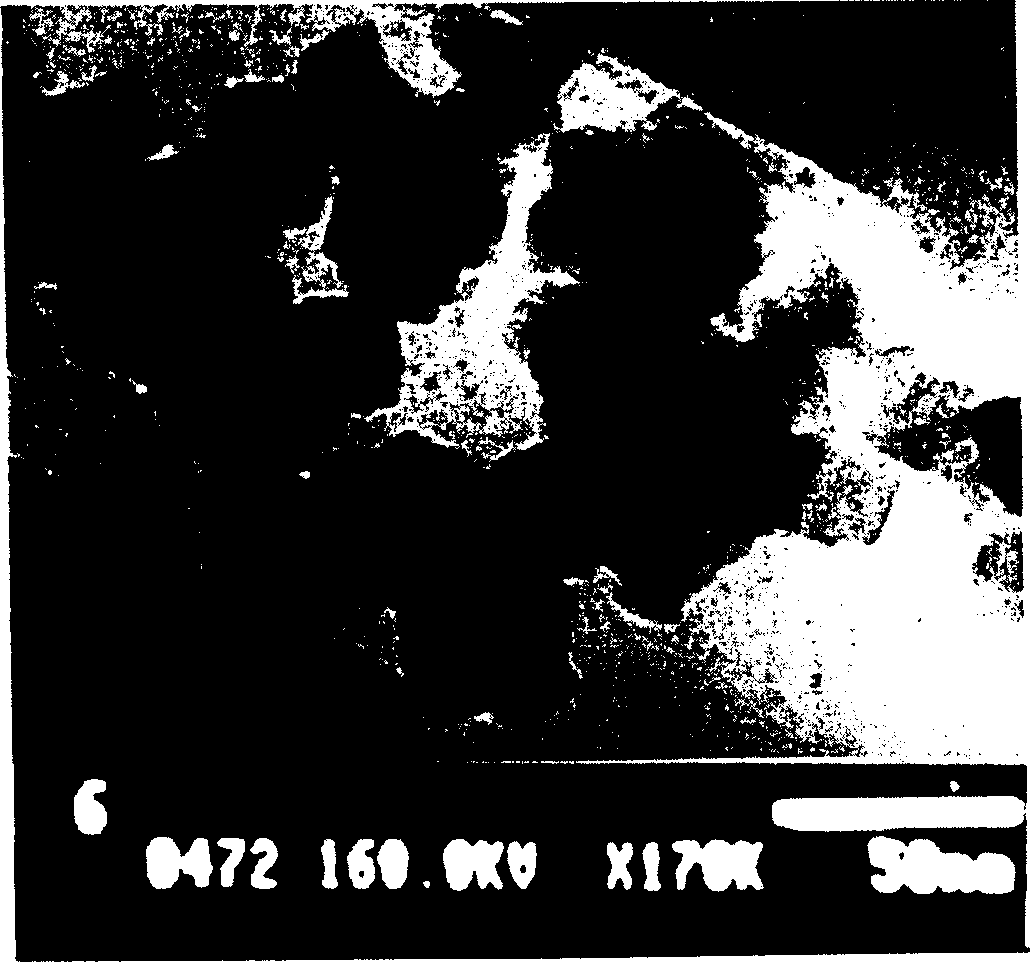

[0035] Add 2% sodium hydroxide to 80% water, under continuous stirring, first add 5% tetraisopropyl titanate dropwise to the aqueous solution of sodium hydroxide, then add 13% tetraethyl orthosilicate in 0.02ml / s speed dropwise into the mixture to obtain a white colloid. Then the colloid was transferred to a simple reactor, and the hydrothermal reaction was carried out at a temperature of 140° C. for 10 days. The obtained solid product was washed with acetone and deionized water respectively, centrifuged and dried in an oven to obtain the desired sample.

[0036] Atomic absorption spectrometry (AAS) was used to determine the concentration of the sample in 0.1M HNO 3, In an aqueous solution of 100ppm cesium, the distribution coefficient of cesium can be as high as 10000ml / g. In the aqueous solution of 0.1M NaOH and 100ppm strontium, the distribution coefficient of strontium can be as high as 15000ml / g. In an aqueous solution of 0.1M NaOH and 100ppm lithium, the distribution...

Embodiment 3

[0038] Add 10% sodium hydroxide to 70% water, under continuous stirring, first add 15% tetraisopropyl titanate dropwise to the aqueous solution of sodium hydroxide, then add 5% tetraethyl orthosilicate in 0.09ml / s speed dropwise into the mixture to obtain a white colloid. Then the colloid was transferred to a simple reactor, and the hydrothermal reaction was carried out at 250° C. for 4 days. The obtained solid product was washed with acetone and deionized water respectively, centrifuged and dried in an oven to obtain the desired sample.

[0039] Atomic absorption spectrometry (AAS) was used to determine the concentration of the sample in 0.1M HNO 3 , In an aqueous solution of 100ppm cesium, the distribution coefficient of cesium can be as high as 11000ml / g. In the aqueous solution of 0.1M NaOH and 100ppm strontium, the distribution coefficient of strontium can be as high as 8000ml / g. In an aqueous solution of 0.1M NaOH and 100ppm lithium, the distribution coefficient for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com