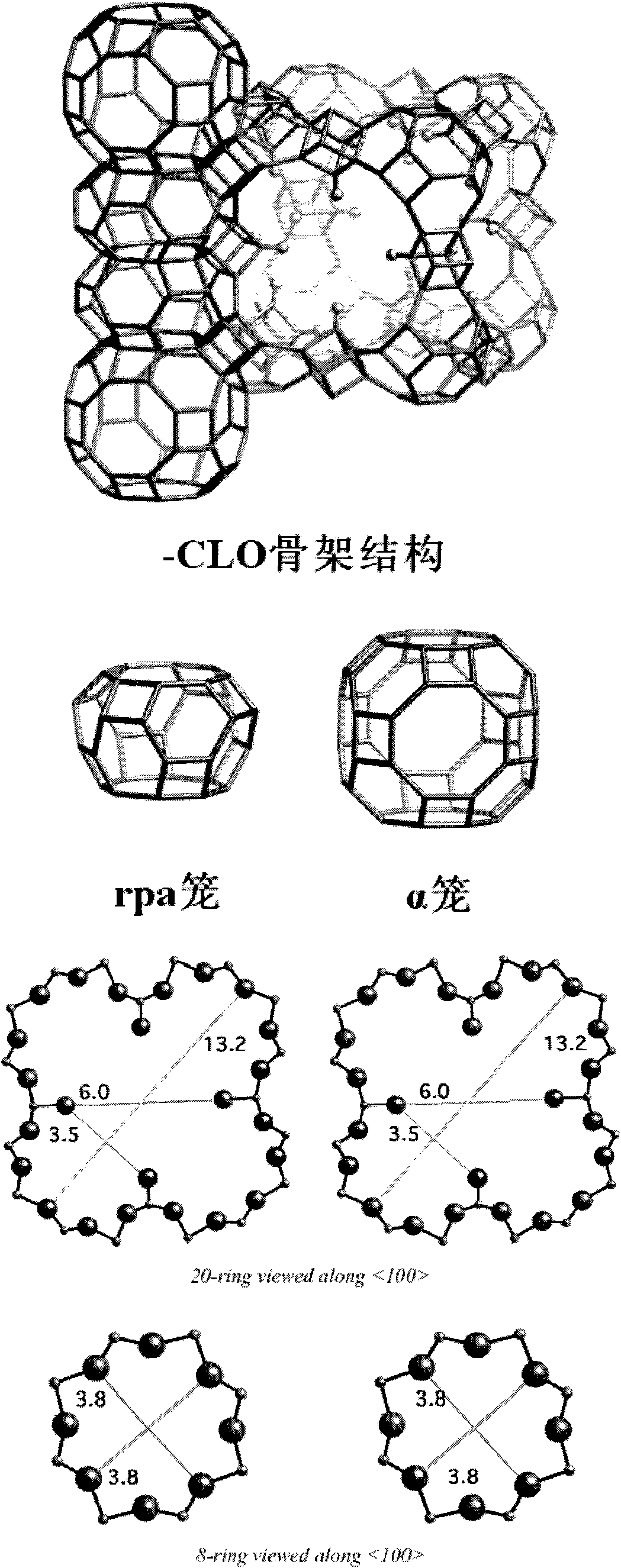

-CLO structural aluminum phosphate molecular sieve and preparation method thereof

A technology of aluminum phosphate molecular sieve and molecular sieve, applied in the field of molecular sieve, can solve the problem of long crystallization time of molecular sieve, and achieve the effects of low synthesis cost, no acid and alkali discharge, safe and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

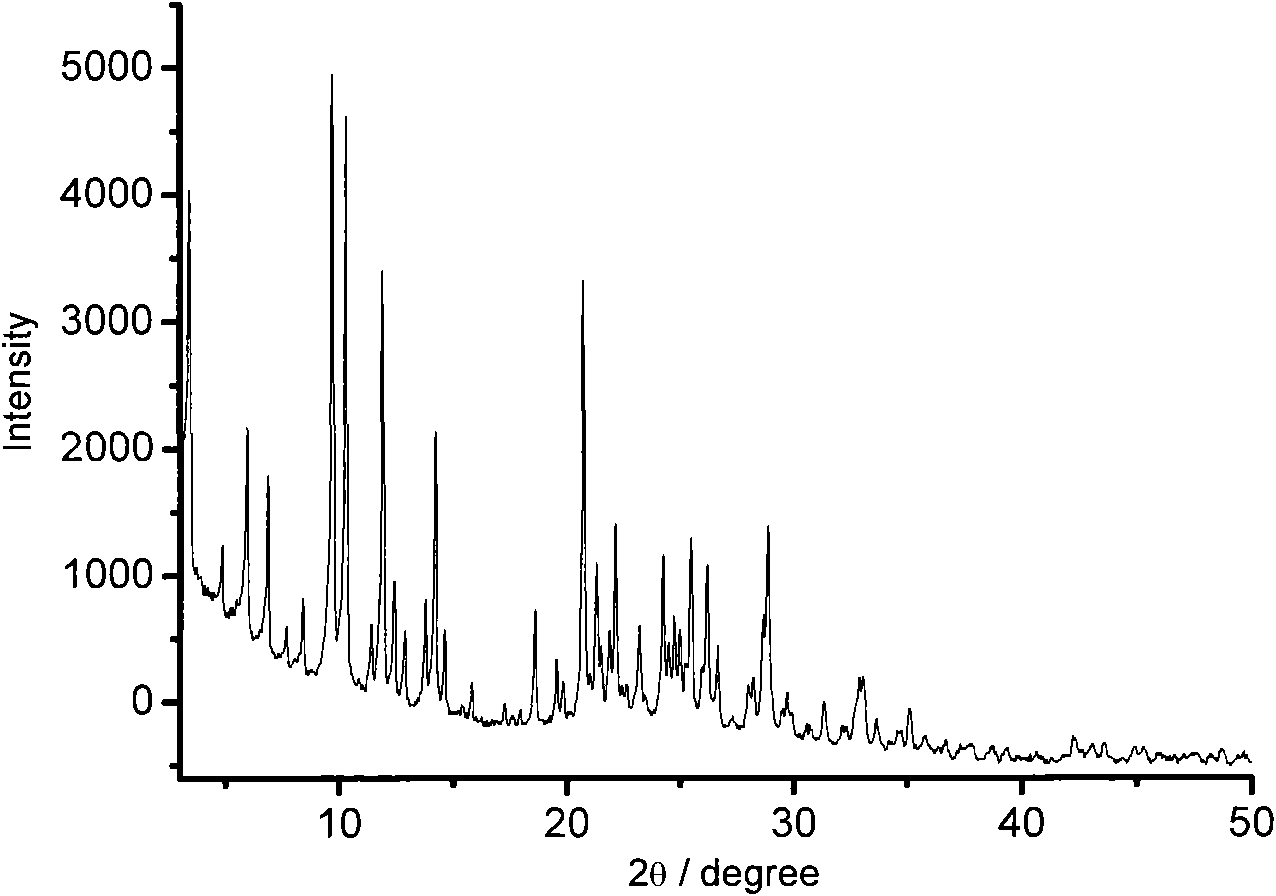

[0033] Add 52.8g of 1-ethyl-3-methylimidazolium bromide ionic liquid (EMIMBr) into a 100ml beaker, heat up to 100°C, add 0.8g of phosphoric acid with a concentration of 85wt%, 1.4g of aluminum isopropoxide, and mix evenly Add 0.41g concentration of 40% hydrofluoric acid dropwise, stir until uniform, then add 0.64g hexamethylenediamine (HDA), continue stirring until uniform to obtain the reaction precursor mixture, the mixture of Al 2 o 3 :P 2 o 5 :F - The ratio of :EMIMBr:HDA (phosphorus and aluminum are expressed in the form of their oxides) is (molar ratio) 1:1:2.4:80:1.6. Transfer the mixture to a 100ml stainless steel reaction kettle with a Teflon liner, put it in an oven at 230°C, and keep it for 1 hour, then cool the reaction mixture to room temperature, add 150ml of deionized water, stir, and wash it ultrasonically. The thing was filtered to obtain a white solid powder, which was washed three times, and the white powder was washed with 50ml of acetone. The final wh...

Embodiment 2

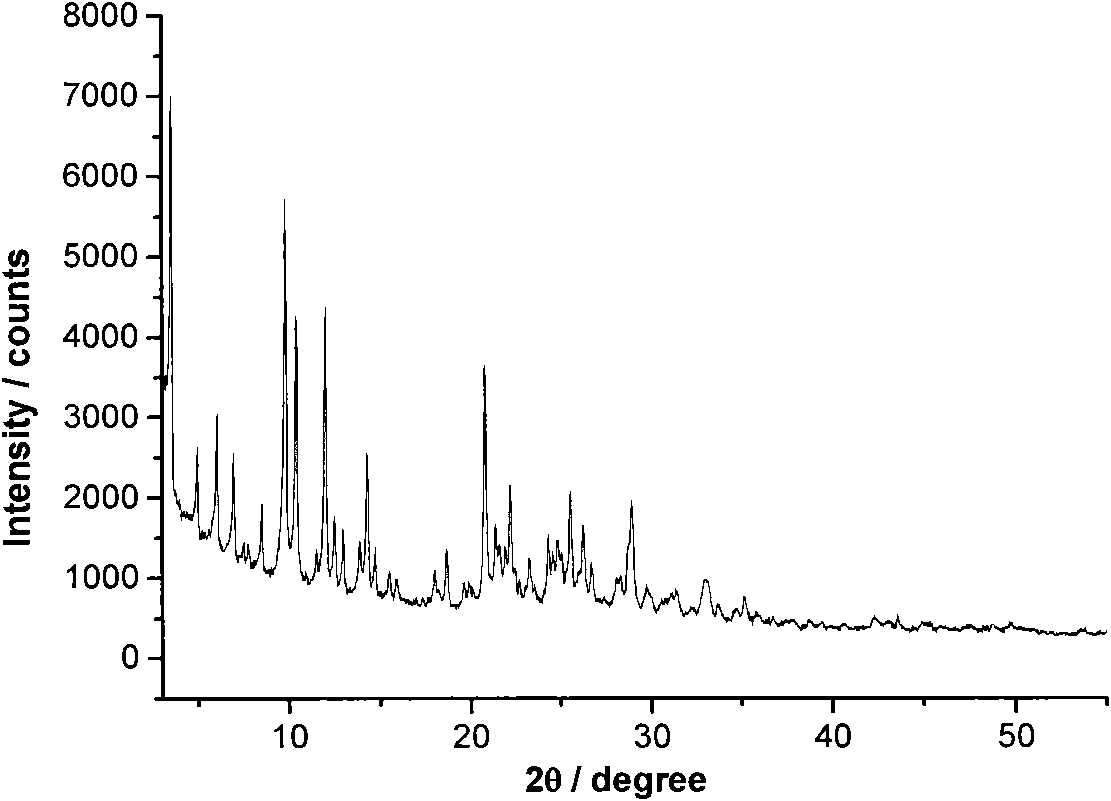

[0035] Add 52.8g of 1-ethyl-3-methylimidazolium bromide ionic liquid (EMIMBr) into a 100ml beaker, heat up to 100°C, add 0.8g of phosphoric acid with a concentration of 85wt%, 1.4g of aluminum isopropoxide, and mix evenly Add 0.34g concentration of 40% hydrofluoric acid dropwise, stir until uniform, then add 0.40g hexamethylenediamine (HDA), continue stirring until uniform to obtain the reaction precursor mixture, the mixture of Al 2 o 3 :P 2 o 5 :F - The ratio of :EMIMBr:HDA (phosphorus and aluminum expressed in the form of their oxides) is (molar ratio) 1:1:2:80:1. Transfer the mixture to a 100ml stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in an oven at 190°C, and keep it for 6 hours, then cool the reaction mixture to room temperature, add 150ml of deionized water, stir, and wash it ultrasonically. The thing was filtered to obtain a white solid powder, which was washed three times, and the white powder was washed with 50ml of acetone. Th...

Embodiment 3

[0037] Add 52.8g of 1-ethyl-3-methylimidazolium bromide ionic liquid (EMIMBr) into a 100ml beaker, heat up to 100°C, add 0.8g of phosphoric acid with a concentration of 85wt%, 1.4g of aluminum isopropoxide, and mix evenly Add 0.16g concentration of 40% hydrofluoric acid dropwise, stir until uniform, then add 0.12g hexamethylenediamine (HDA), continue stirring until uniform to obtain the reaction precursor mixture, the mixture of Al 2 o 3 :P 2 o 5 :F - The ratio of :EMIMBr:HDA (phosphorus and aluminum are expressed in the form of their oxides) is (molar ratio) 1:1:0.8:80:0.3. Transfer the mixture to a 100ml stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in an oven at 150°C, and keep it for 12 hours, then cool the reaction mixture to room temperature, add 150ml of deionized water, stir, and wash it ultrasonically. The thing was filtered to obtain a white solid powder, which was washed three times, and the white powder was washed with 50ml of ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com