Method for synthesizing ordered mesoporous titanium oxide molecular sieve

A technology of mesoporous titanium oxide and synthesis method, applied in the direction of molecular sieve characteristic aluminum phosphate, crystalline aluminosilicate zeolite, etc., can solve the problems of difficult matching, inability to form an ordered mesoscopic structure, and fast hydrolysis speed of titanium source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

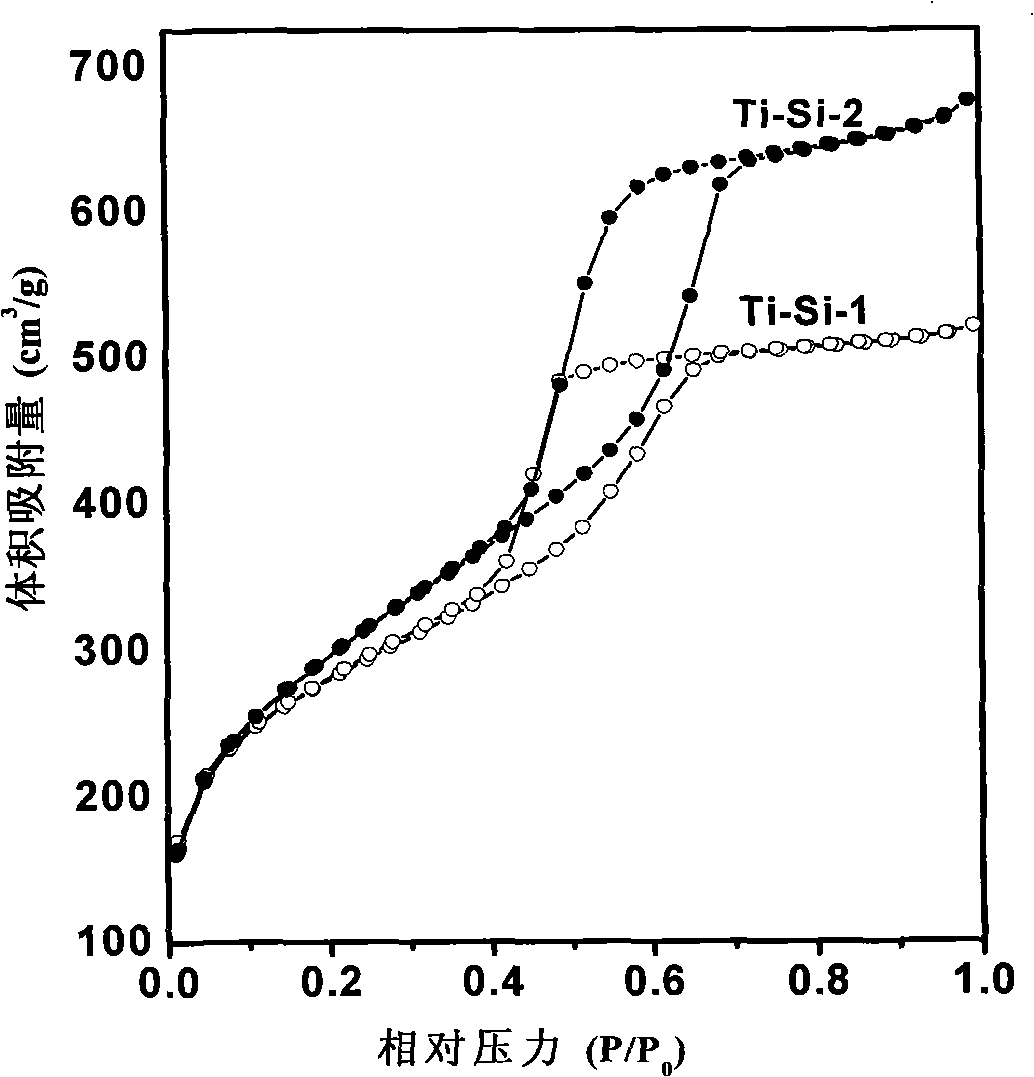

[0028] Example 1: Preparation of mesoporous titanium oxide silicon molecular sieve with Si / Ti molar ratio of 20.

[0029] Step 1: At 40°C, mix 2.0g P123, 30g 1M hydrochloric acid, 15g H 2 O mixed, stirred at 40°C until all surfactants were dissolved, then added 4.23mL TEOS and continued to stir for 4 hours.

[0030] Step 2: Stir 8.0 mL of isopropanol, 0.043 mL of titanium tetrachloride, and 0.204 mL of n-butyl titanate at 40° C. for 2 hours. The solution described in mixing step 1 was continued to stir at the same temperature for 20 hours. The obtained mixed solution was transferred to an oven at 80° C. to volatilize for 2 hours, then transferred to a polytetrafluoroethylene hydrothermal kettle, and reacted hydrothermally in an oven at 100° C. for 1 day. After cooling, white powder was obtained after suction filtration, washing and natural drying at room temperature.

[0031] Step 3: Calcining 1.5 g of the sample without removing the surfactant at 450° C. for 8 hours in the...

Embodiment 2

[0033]Example 2: Preparation of mesoporous titania silica molecular sieve with Si / Ti molar ratio of 12.5.

[0034] Step 1: At 20°C, mix 2.0g P123, 30g 1M hydrochloric acid, 15g H 2 O mixed, stirred at 20°C until all surfactants were dissolved, then added 4.04mL TEOS and continued to stir for 4 hours.

[0035] Step 2: Stir 8.0 mL of isopropanol, 0.070 mL of titanium tetrachloride, and 0.310 mL of n-butyl titanate at 20° C. for 2 hours. The solution described in mixing step 1 was continued to stir at the same temperature for 28 hours. Transfer the obtained mixed solution to a 70°C oven to volatilize for 4 hours, then transfer it to a polytetrafluoroethylene hydrothermal kettle, and conduct a hydrothermal reaction in a 100°C oven for 1 day. A white powder was obtained after drying.

[0036] Step 3: Calcining 1.5 g of the sample without removing the surfactant at 350° C. for 15 hours in the air, and the obtained white powder is the product.

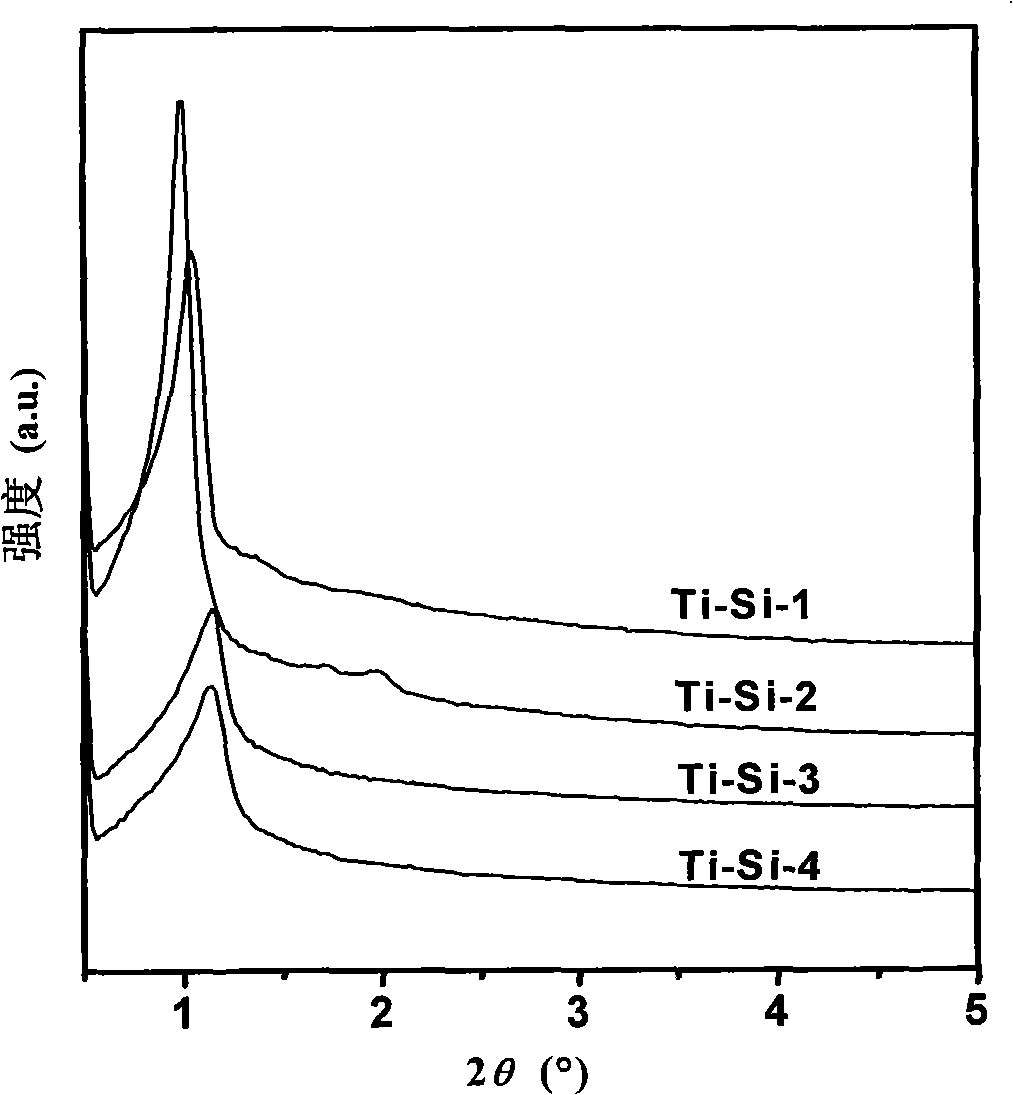

[0037] The product is a two-dimens...

Embodiment 3

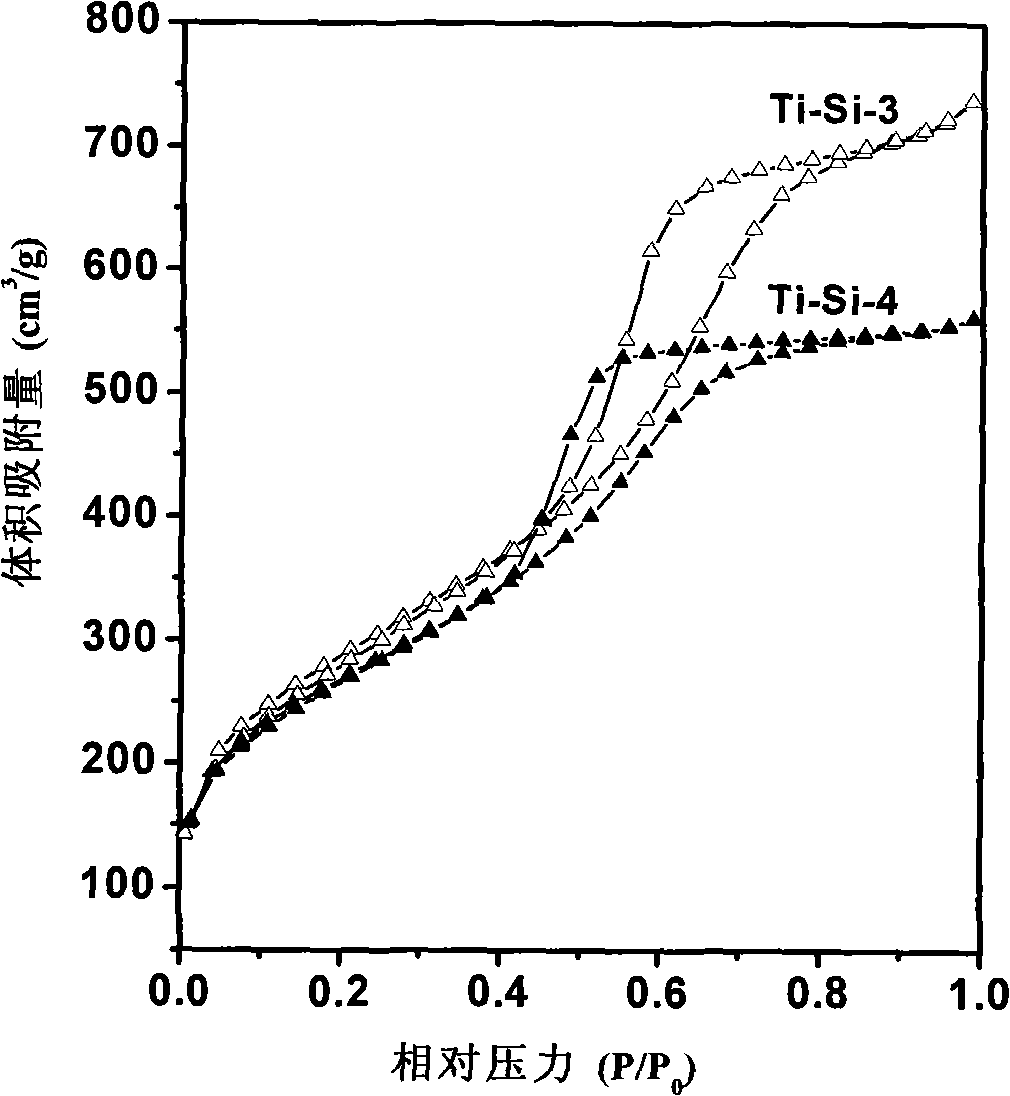

[0038] Example 3: Preparation of a titania-silicon molecular sieve with a Si / Ti molar ratio of 10.

[0039] Step 1: At 30°C, mix 2.0g P123, 30g 1M hydrochloric acid, 15g H 2 O mixed, stirred at 40°C until all surfactants were dissolved, then added 4.00 mL TEOS and continued to stir for 3 hours.

[0040] Step 2: Stir 8.0 mL of isopropanol, 0.090 mL of titanium tetrachloride, and 0.410 mL of n-butyl titanate at 30° C. for 2 hours. The solution described in mixing step 1 was continued to stir at the same temperature for 40 hours. Transfer the obtained mixed solution to an oven at 80°C to volatilize for 2 hours, then transfer it to a polytetrafluoroethylene hydrothermal kettle, and react hydrothermally in an oven at 100°C for 1 day. A white powder was obtained after drying.

[0041] Step 3: Calcining 1.5 g of the sample without removing the surfactant at 550° C. for 10 hours in the air, and the obtained white powder is the product.

[0042] The product is a two-dimensional hex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com