Solid-phase synthesizing method of flaky lamellar SAPO-34

A SAPO-34, solid-phase synthesis technology, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, molecular sieves and alkali-exchanged phosphate, etc., can solve poor stability, low crystallinity in solid-phase production, crystallinity Low-level problems, to achieve the effect of strong anti-carbon deposition, high crystallinity, and prolonged catalytic life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] With the initial gel molar ratio as 50H 2 O: 0.2SiO 2 (Silica sol): 1.0Al 2 o 3 (pseudoboehmite): 1.0P 2 o 5 : 0.5TEA: 0.05NaF to prepare a gel (code S-0.05NaF), age at room temperature for 8 hours, then transfer to a 90°C oven to dry overnight to obtain a dry gel, crush the dry gel, weigh 20g and place it in a polyamide Fluoride beaker. Take a 200ml reaction kettle, add 10gH to the bottom of the kettle 20, 5g TEA, place the polytetrafluoro beaker with dry glue on the upper layer of the kettle liquid, seal it and place it in a 200°C oven for crystallization for 48h, and place the dry powder sample in a 550°C muffle furnace for 300min roasting after the reaction , the final product can be obtained.

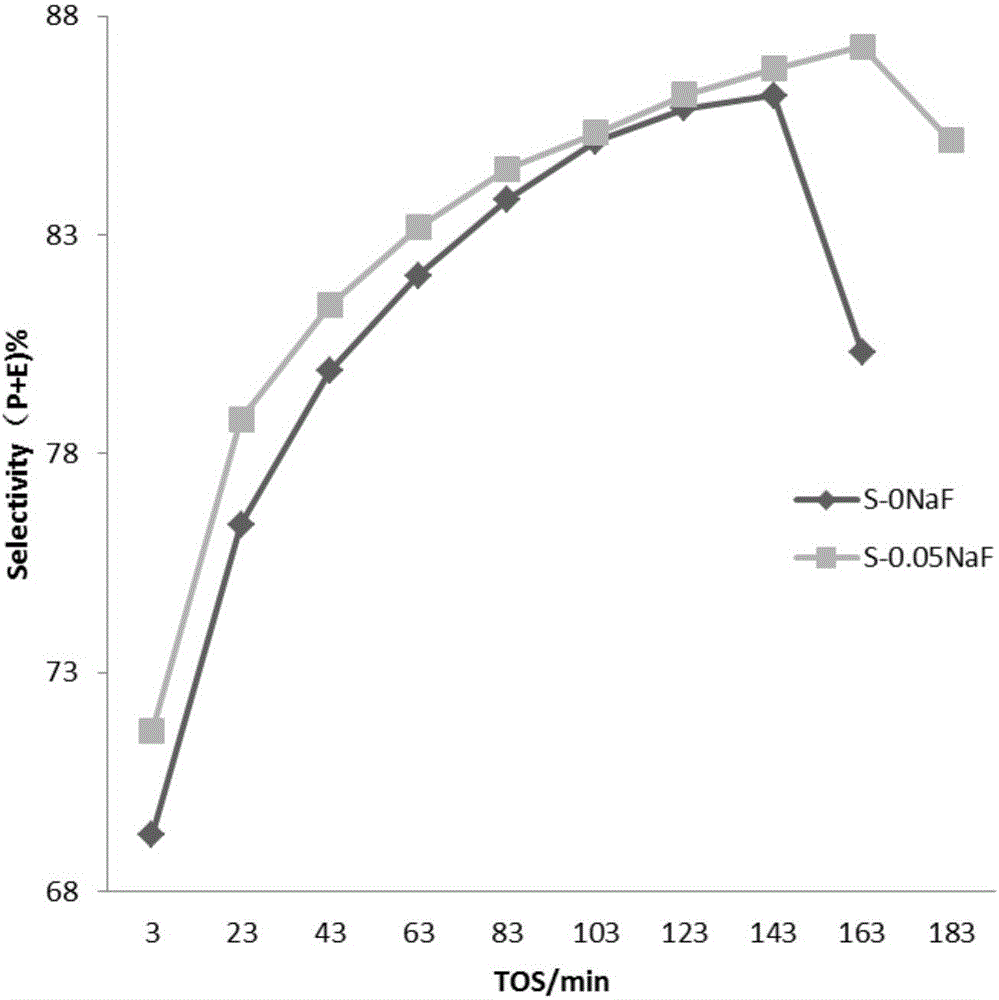

[0038] The S-0.05NaF obtained in Example 1 was granulated, and 1.0 g of 40-60 mesh particle samples were weighed for the fixed-bed methanol-to-olefin reaction. The samples were loaded into the constant temperature zone of the reactor, and both ends were filled with qu...

Embodiment 2

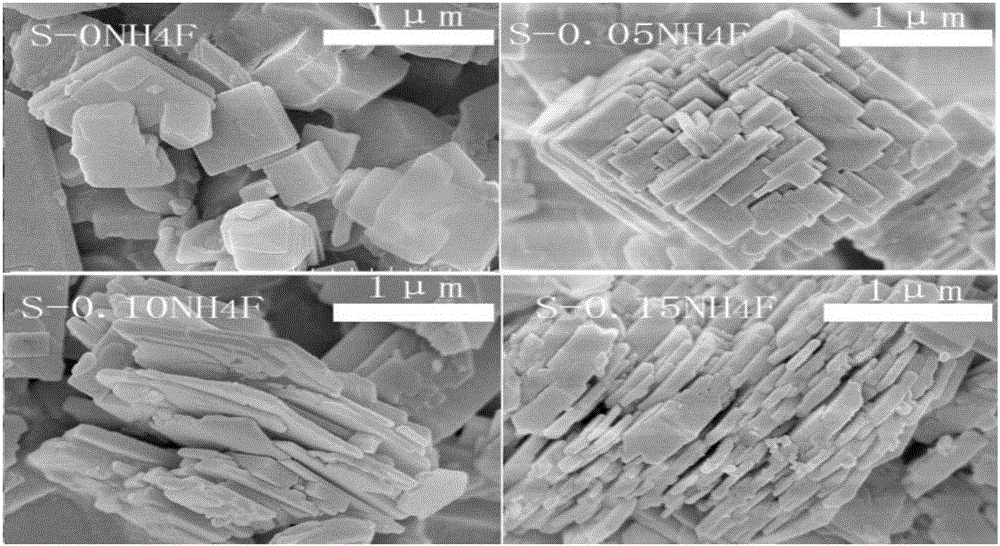

[0040] With the initial gel molar ratio as 50H 2 O: 0.2SiO 2 (Silica): 1.0Al 2 o 3 (pseudoboehmite): 1.0P 2 o 5 :0.5TEA: x NH 4 F prepares gel, wherein x=0(S-ONH 4 F), x=0.05(S-0.05NH 4 F), x=0.10(S-0.10NH 4 F), x=0.15(S-0.15NH 4 F), aged at room temperature for 8 hours, then transferred to an oven at 90°C to dry overnight to obtain dry glue, crushed dry glue, weighed 20 g and placed it in a polytetrafluoro beaker. Take a 200ml reaction kettle, add 10gH to the bottom of the kettle 2 0. 5gTEA, place the polytetrafluoro beaker with dry glue on the upper layer of the kettle liquid, seal it and place it in a 200°C oven for crystallization for 48h, and place the dry powder sample in a 550°C muffle furnace for roasting for 300min after the reaction. The final product can be obtained, and its SEM analysis is as follows: figure 2 shown.

Embodiment 3

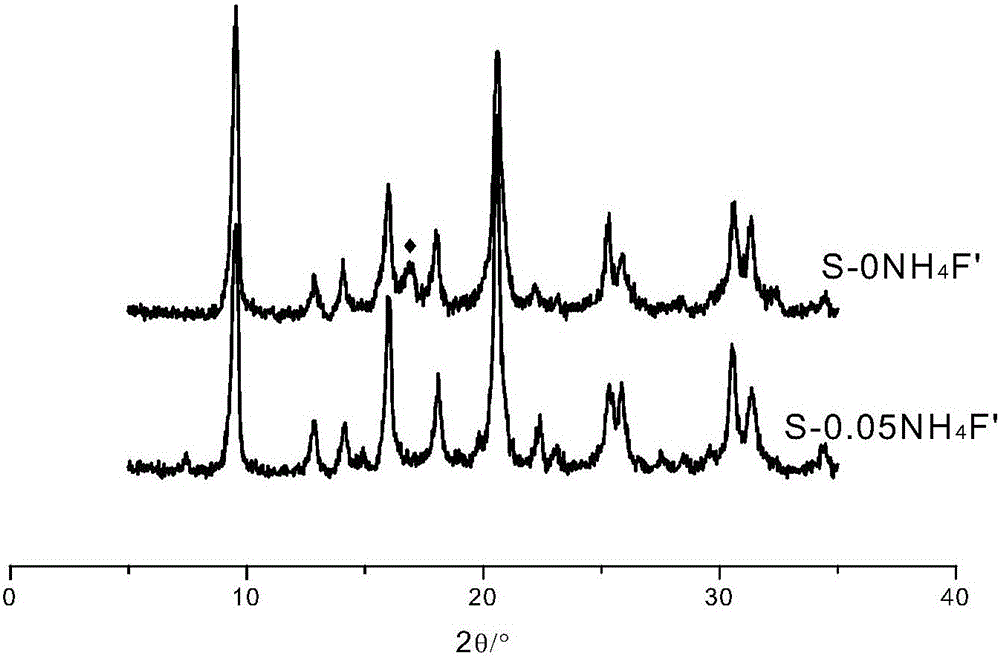

[0042] With the initial gel molar ratio as 50H 2 O: 0.15TEOS (orthoethyl silicate): 1.0Al 2 o 3 (Aluminum isopropoxide): 1.0P 2 o 5 :1.0DEA:x NH 4 F Prepare the gel. x=0(S-0NH 4 F'), x=0.05(S-0.05NH 4 F') Aging at room temperature for 8 hours, and then transferred to a 90°C oven to dry overnight to obtain dry glue. After crushing the dry glue, weigh 20 g and place it in a polytetrafluoro beaker. Take a 200ml reaction kettle, add 10g H2O and 5g TEA to the bottom of the kettle, place a polytetrafluoro beaker with dry glue on the upper layer of the kettle liquid, seal it and place it in a 200°C oven for crystallization for 48h, after the reaction is over, put the dry powder The sample is placed in a muffle furnace at 550°C and roasted for 300 minutes to obtain the final product. The XRD analysis is as follows: image 3 As shown, the NH3-TPD analysis is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com