A carried-type aluminium dihydrogen tripolyphosphate catalyst and a preparation method thereof

A technology of aluminum dihydrogen tripolyphosphate and catalyst, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of insignificant catalytic effect and insignificant improvement of catalytic effect, and achieve economic benefits. and social benefits, the reaction conditions are not high, and the effect of improving the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

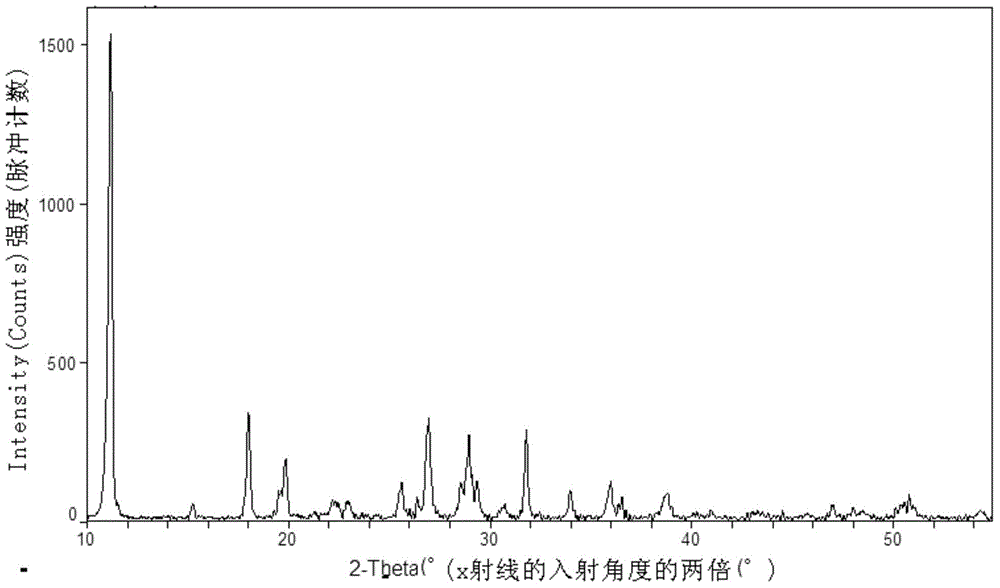

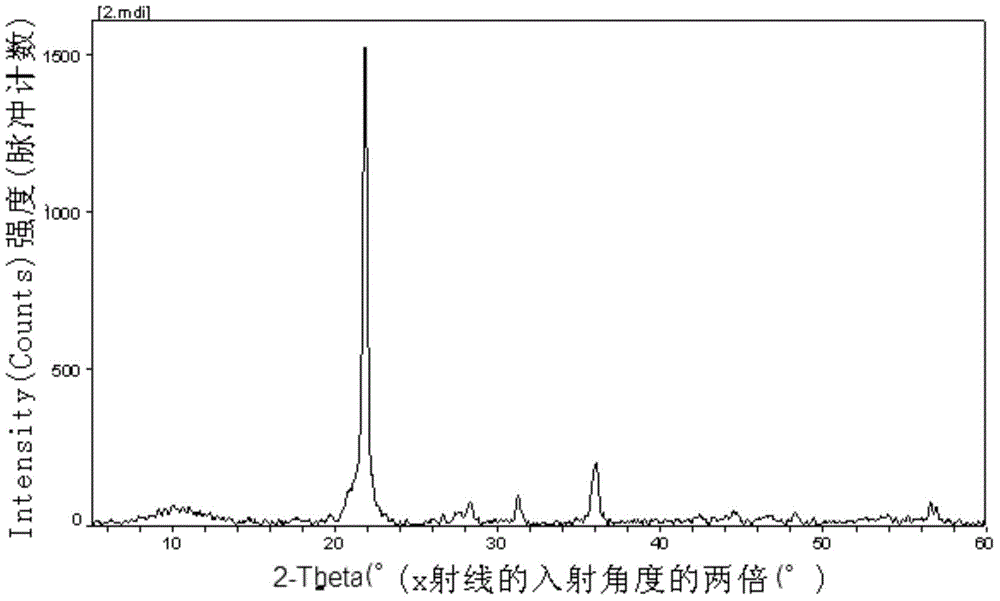

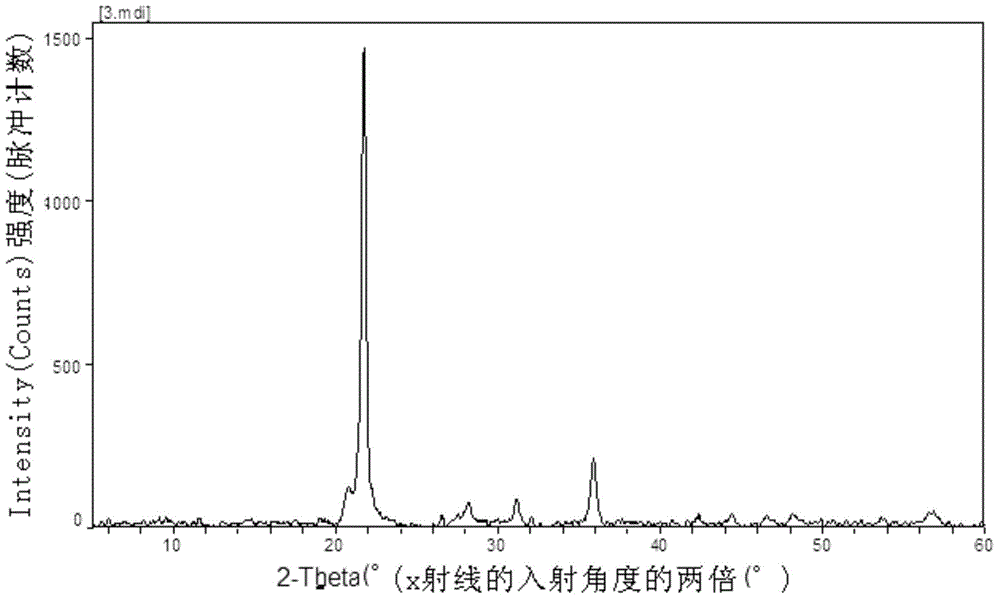

Image

Examples

Embodiment 1

[0044] 1. Raw material composition and mass quantity:

[0045]5 grams of sublimated sulfur, 200 grams of diatomaceous earth, 200 grams of water, 34.5 grams of phosphoric acid, and 8 grams of aluminum hydroxide.

[0046] 2. Preparation method:

[0047] Take 5 grams of sublimated sulfur in a crucible and 200 grams of diatomite on a porcelain plate, put them into a muffle furnace at the same time, heat to 500 ° C, keep for 3 hours, take out after cooling and grind to obtain sulfur-loaded diatomite.

[0048] Pour 34.5 grams of phosphoric acid and 20 grams of water into a beaker, heat on an electric furnace, stir, and slowly add 8 grams of aluminum hydroxide when the temperature of the solution is 70-80°C, continue heating and stirring, and control the temperature of the solution at 100-110°C , stop the reaction until the solution becomes transparent, and cool down to obtain the phosphorus-aluminum intermediate.

[0049] Add 60 grams of water to the above-mentioned cooled phospho...

Embodiment 2

[0051] 1. Raw material composition and mass quantity:

[0052] 10 grams of sublimated sulfur, 280 grams of activated clay, 280 grams of water, 38 grams of phosphoric acid, and 8 grams of aluminum hydroxide.

[0053] 2. Preparation method:

[0054] Take 10 grams of sublimated sulfur in a crucible and 280 grams of activated clay on a porcelain plate, put it into a muffle furnace at the same time, heat it to 700°C, keep it for 2 hours, take it out after cooling, and grind it to obtain sulfur-loaded activated clay.

[0055] Pour 38 grams of phosphoric acid and 30 grams of water into a beaker, place it on an electric furnace, stir, and slowly add 8 grams of aluminum hydroxide when the temperature of the solution is 70-80 ° C, continue heating and stirring, and control the temperature of the solution at 100-110 ° C, Stop the reaction until the solution becomes transparent, and cool to obtain the acid aluminum intermediate.

[0056] Add 100 grams of water to the above-mentioned coo...

Embodiment 3

[0058] 1. Raw material composition and mass quantity:

[0059] 20 grams of pyrite, 400 grams of activated carbon, 170 grams of water, 32 grams of phosphoric acid, and 5.2 grams of activated alumina.

[0060] 2. Preparation method:

[0061] Take 20 grams of pyrite in a crucible and 400 grams of activated carbon on a porcelain plate, put it into a muffle furnace at the same time, heat it to 800 ° C, keep it for 4 hours, take it out after cooling, and grind it to obtain sulfur-loaded activated carbon.

[0062] Pour 32 grams of phosphoric acid and 20 grams of distilled water into a beaker, place it on an electric furnace, stir, and slowly add 5.2 grams of activated alumina when the temperature of the solution is 70-80 ° C, continue heating and stirring, and control the temperature of the solution at 100-110 ° C, Stop the reaction until the solution becomes transparent, and cool to obtain the phosphorus-aluminum intermediate.

[0063] Add 50 grams of water to the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com