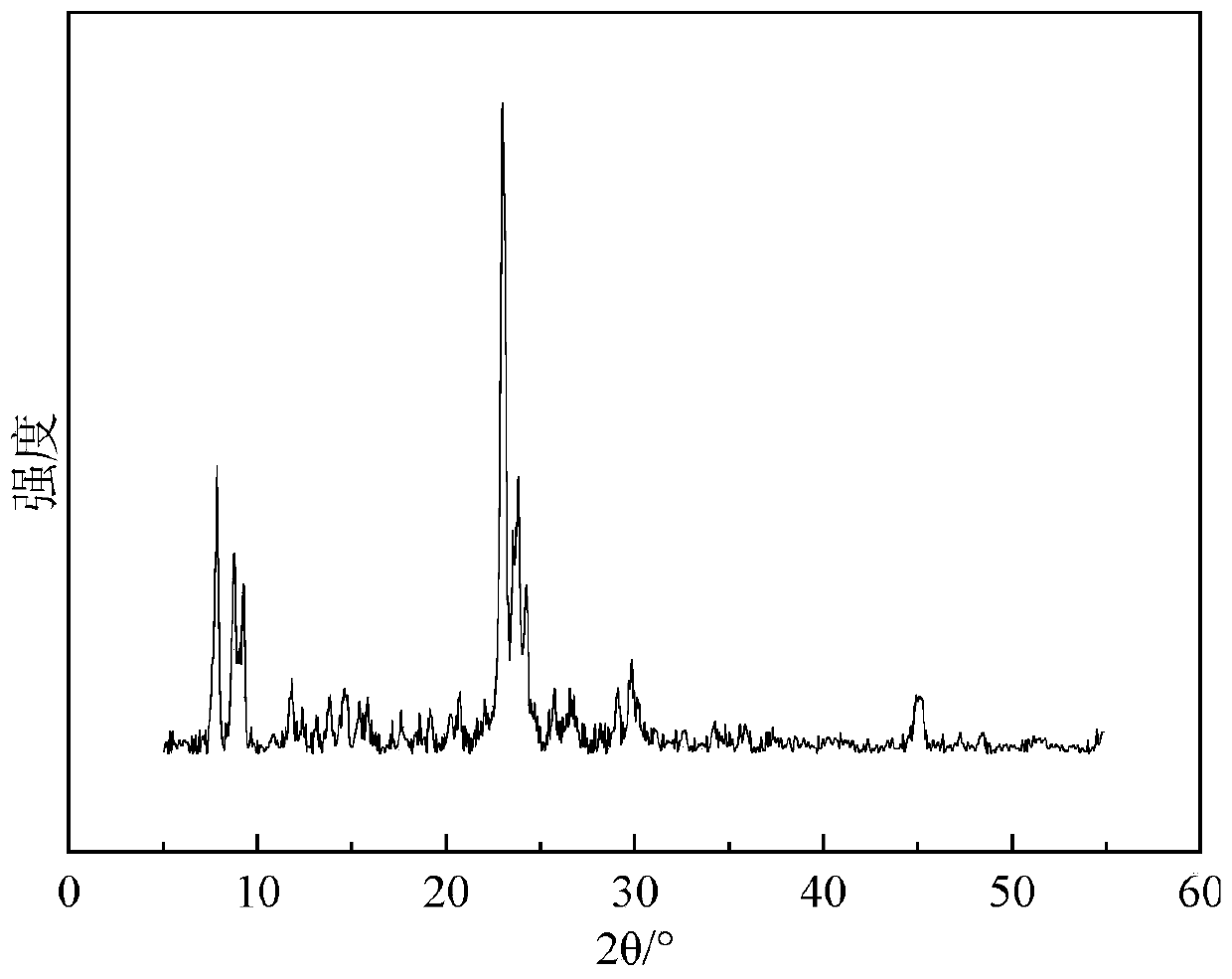

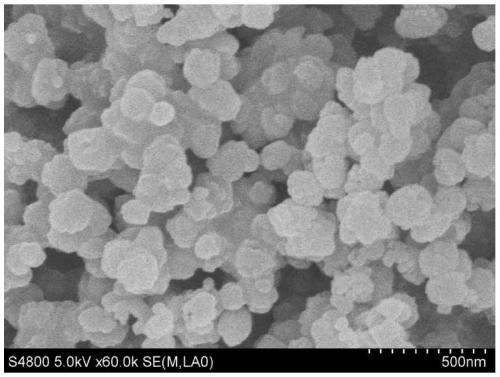

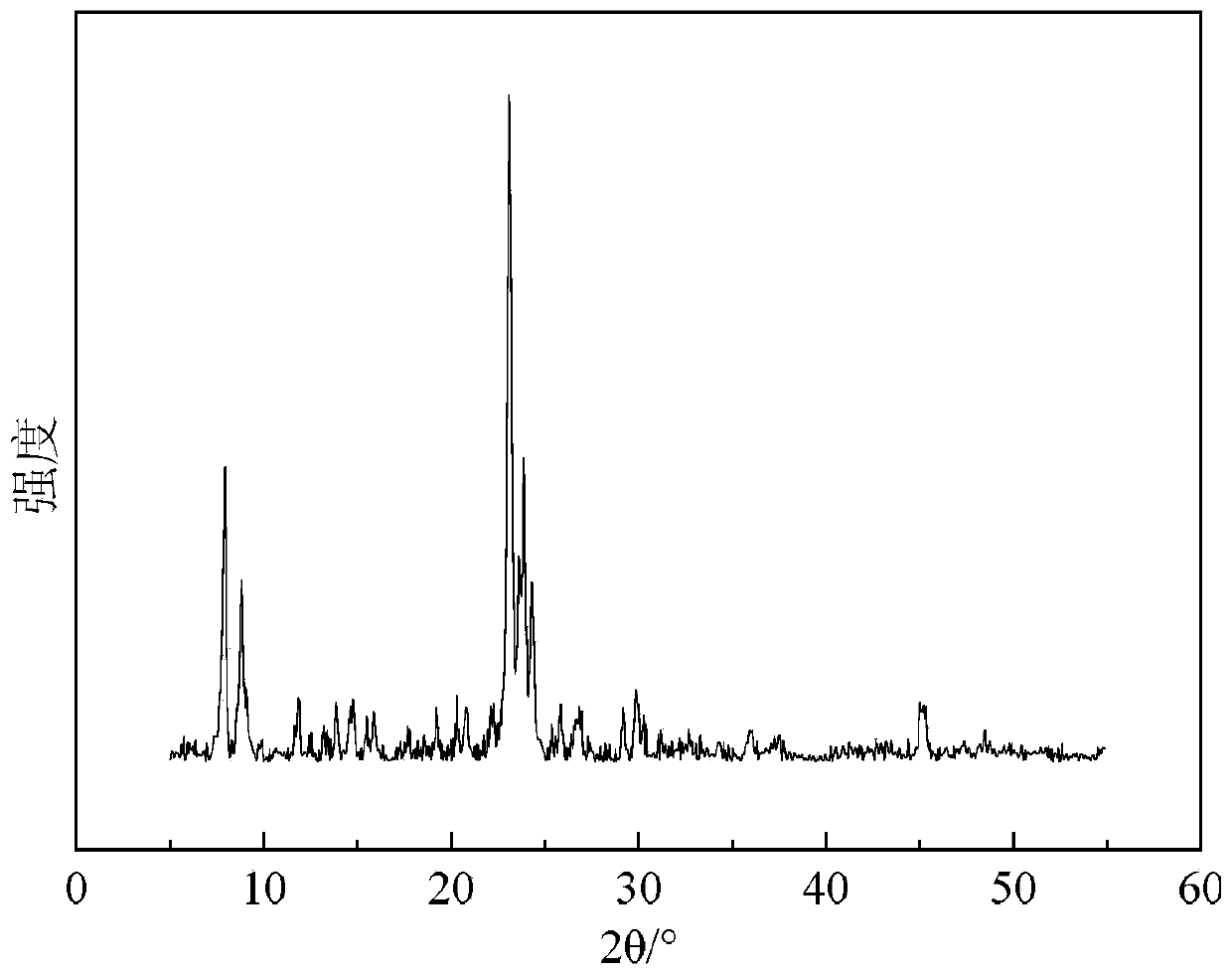

Method for in-situ synthesis of nano Zn/Al-ZSM-5 molecular sieve with steam-assisted dry glue conversion method

A technology of dry rubber conversion and in-situ synthesis, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large molecular sieve grain size, long crystallization time, and high energy consumption. The effect of shortening the curing time, reducing the acid strength and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific implementation mode one: the method for synthesizing nano Zn / Al-ZSM-5 molecular sieve in situ by steam-assisted dry rubber conversion method in this embodiment is implemented according to the following steps:

[0025] 1. Weigh 1 part of aluminum isopropoxide, 21 to 85 parts of tetrapropylammonium hydroxide aqueous solution, 33 to 136 parts of ethyl orthosilicate, 0.9 to 1.0 parts of zinc nitrate hexahydrate and 27-110 parts of deionized water as raw material;

[0026] The mass percentage composition of tetrapropyl ammonium hydroxide in the tetrapropyl ammonium hydroxide aqueous solution described therein is 54.78%;

[0027] 2. Add aluminum isopropoxide and tetrapropylammonium hydroxide aqueous solution into deionized water and stir evenly to form A solution; under stirring conditions, add the solution of zinc nitrate hexahydrate dissolved in deionized water to A solution , and stir evenly to form B solution; then add tetraethyl orthosilicate dropwise to B solu...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that step 1 weighs 1 part of aluminum isopropoxide, 21 to 60 parts of tetrapropylammonium hydroxide aqueous solution, 33 to 90 parts of Ethyl orthosilicate, 0.9-1.0 parts of zinc nitrate hexahydrate and 27-80 parts of deionized water.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, aluminum isopropoxide and tetrapropyl ammonium hydroxide aqueous solution and deionized water in the raw material are mixed at a stirring speed of 750-800r / min Stirring for 10-20min under the conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com