Carbon dioxide electrochemical reduction conversion utilization method

一种二氧化碳、电化学的技术,应用在电化学发生器、电极、电路等方向,能够解决催化剂利用率和产率低等问题,达到提高循环利用率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

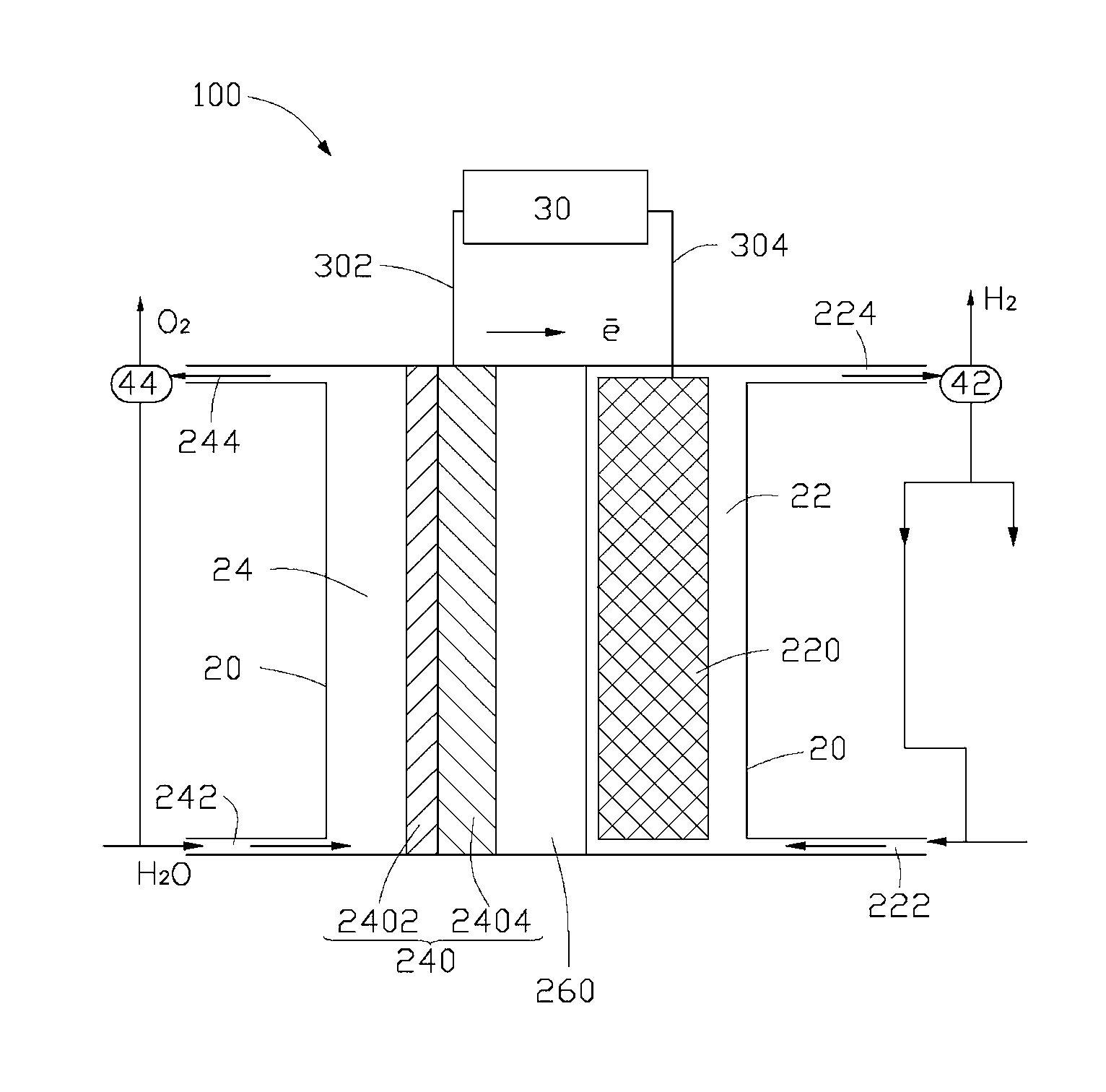

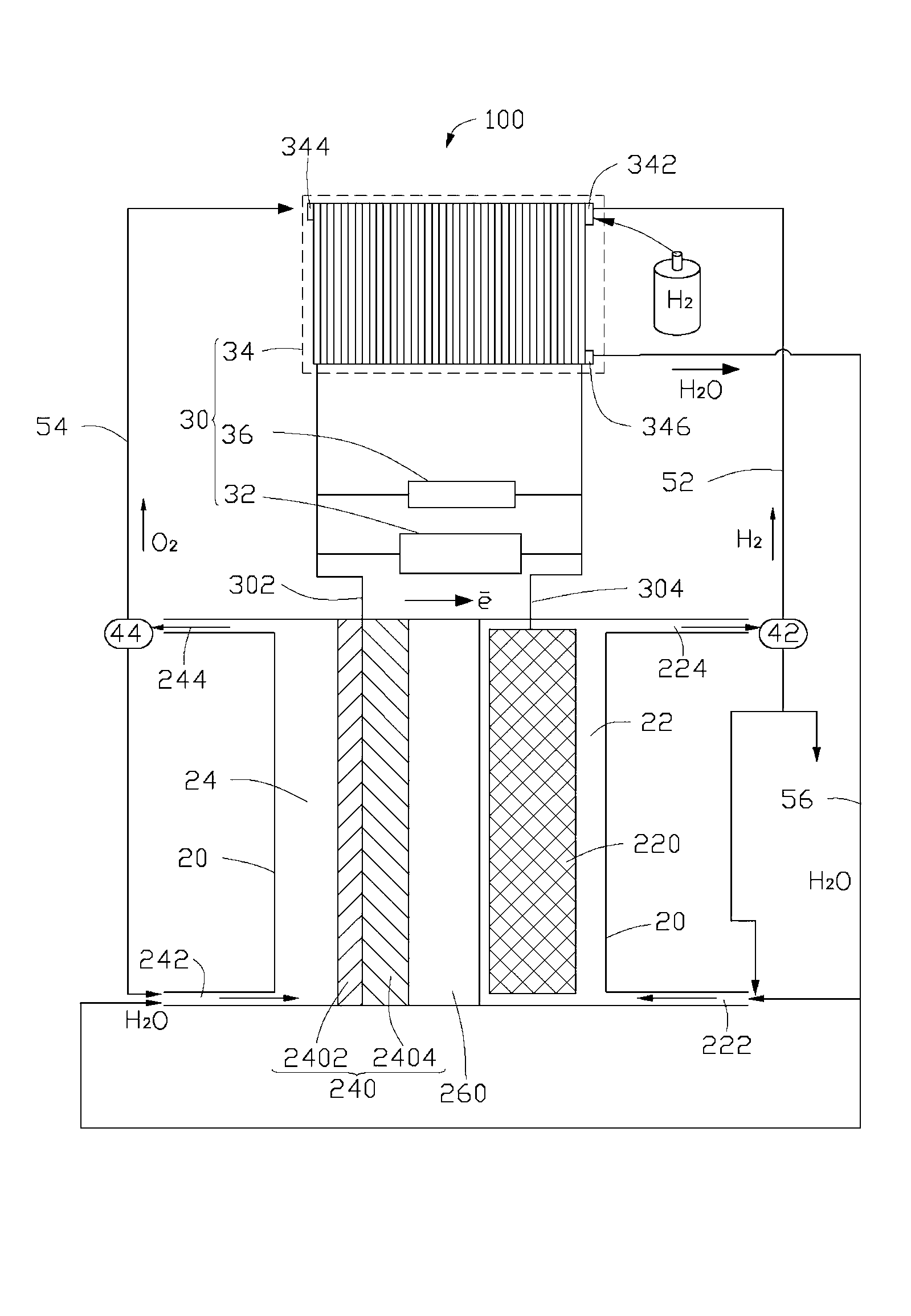

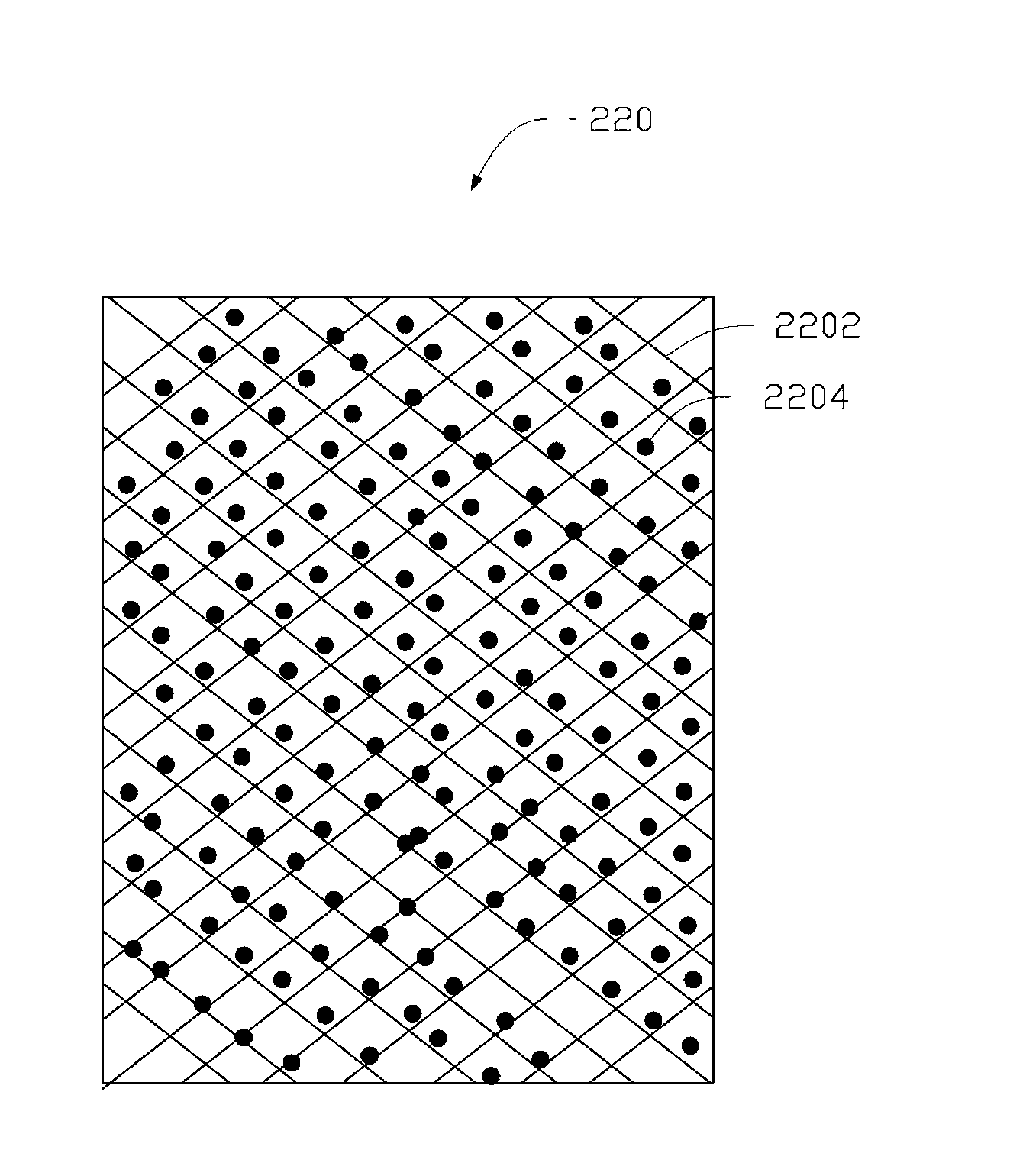

[0044] CO 2 The cathode 220 of the membrane reactor 10 used in the electrochemical reduction conversion uses a 10 mm thick porous titanium mesh as the porous support layer, and the porous support layer has an opening ratio of 60%. Highly dispersed Sn / Cu alloy particles are selected as the cathode catalyst, and the cathode catalyst particles are uniformly deposited in the pores of the porous support layer. In the anode 240, graphite carbon paper is used as the porous diffusion layer 2402, Ni powder is selected as the anode catalyst, and the Ni powder is plated on the surface of the graphite carbon paper to form the anode 240. The electrolyte diaphragm 260 is a perfluorosulfonic acid cation exchange membrane reinforced with polytetrafluoroethylene mesh, and the electrolyte diaphragm 260 and the anode 240 are hot-pressed to form a composite structure. The thickness of the perfluorosulfonic acid cation exchange membrane is 150 microns. An air-cooled proton exchange membrane fuel...

Embodiment 2

[0047] The structure of this embodiment membrane reactor 10 and the membrane reactor in embodiment 1 and CO 2 The electrochemical conversion process is basically the same, the difference is:

[0048] The porous support layer of the cathode 220 of the membrane reactor 10 is a porous nickel mesh with a thickness of 2.1 mm and a porosity of 31%. The cathode catalyst adopts Cd / In alloy, and is electroplated on the supporting frame of the porous nickel mesh. The anode catalyst uses MnO 2 and Ag powder mixture. The electrolyte diaphragm 260 is a perfluorocarboxylic acid cation exchange membrane reinforced by a porous polytetrafluoroethylene membrane. The enhanced perfluorocarboxylic acid cation exchange membrane has a thickness of 52 microns. A self-humidifying proton exchange membrane fuel cell is used as the electrochemical power source 34 . CO 2 Produced by winter heating boilers. Catholyte using KHCO 3 of aqueous solution. The electrolysis voltage is 3.5V. The product ...

Embodiment 3

[0050] The structure of the membrane reactor 10 in this embodiment and the membrane reactor 10 in Example 1 and the CO 2 The electrochemical conversion process is basically the same, the difference is:

[0051] The porous support layer of the cathode 220 of the membrane reactor 10 is a porous stainless steel mesh with a thickness of 20 mm and a porosity of 90%. The cathode catalyst adopts mixed particles of Bi and Zn, and is electroplated on the support skeleton of the porous stainless steel mesh. Porous nickel mesh is used as the porous diffusion layer 2402 of the anode 240, and the anode catalyst is LaNi 5 and Co powder mixture, LaNi 5 and Co powder are sprayed on the porous diffusion layer 2402 to form the anode catalyst layer 2404 . The electrolyte diaphragm 260 is a reinforced perfluorosulfonic acid / carboxylic acid composite cation exchange membrane. The perfluorosulfonic acid / carboxylic acid composite cation exchange membrane has a thickness of 200 microns. A solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com